Detection device and device method for packaging effect of soft pack lithium batteries

A soft-pack lithium battery and detection device technology, which is applied in the direction of testing fluid tightness by detecting the dimensional change of the structural components to be tested, and using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of injecting electrolyte, easy leakage detection Problems such as poor packaging position and long test cycle can achieve the effect of comprehensive inspection, significant application effect and short inspection cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for detecting the encapsulation effect of a soft pack lithium battery, the steps are as follows:

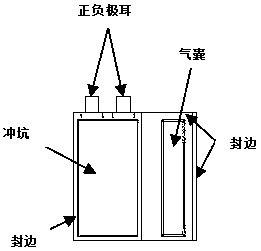

[0041] (a) Dig the DNP aluminum-plastic film with a thickness of 152 μm, and the depth of both pits is 6 mm;

[0042] (b) Fix the tabs at the corresponding positions of the positive and negative tabs of the aluminum-plastic film, and perform top sealing and edge sealing on both sides;

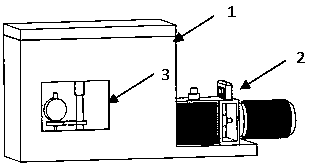

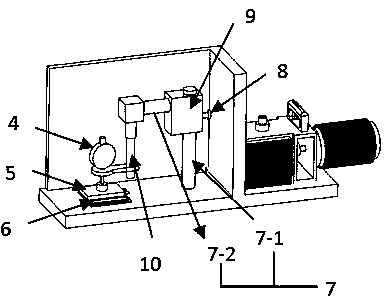

[0043] (c) Put the packaged aluminum-plastic film under the pressure plate 5 of the above-mentioned vacuum chamber 1 after the temperature drops to room temperature, and the pressure plate 5 is in contact with the surface of the aluminum-plastic film, and close the vacuum chamber 1;

[0044] (d) Start the vacuum pump to slowly evacuate the vacuum chamber 1, and its internal pressure value reaches -90KPa;

[0045](e) As the internal air pressure increases, the volume of the aluminum-plastic film changes, driving the pressure plate 5 to rise, and the change in the height of the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com