Enzyme highly concentrated laundry detergent

A high-concentration and laundry detergent technology, applied in the field of laundry detergent, can solve the problems of easy floc or spherical shape, affect the laundry effect, and poor decontamination effect, and achieve low surface tension, excellent coupling agent effect, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

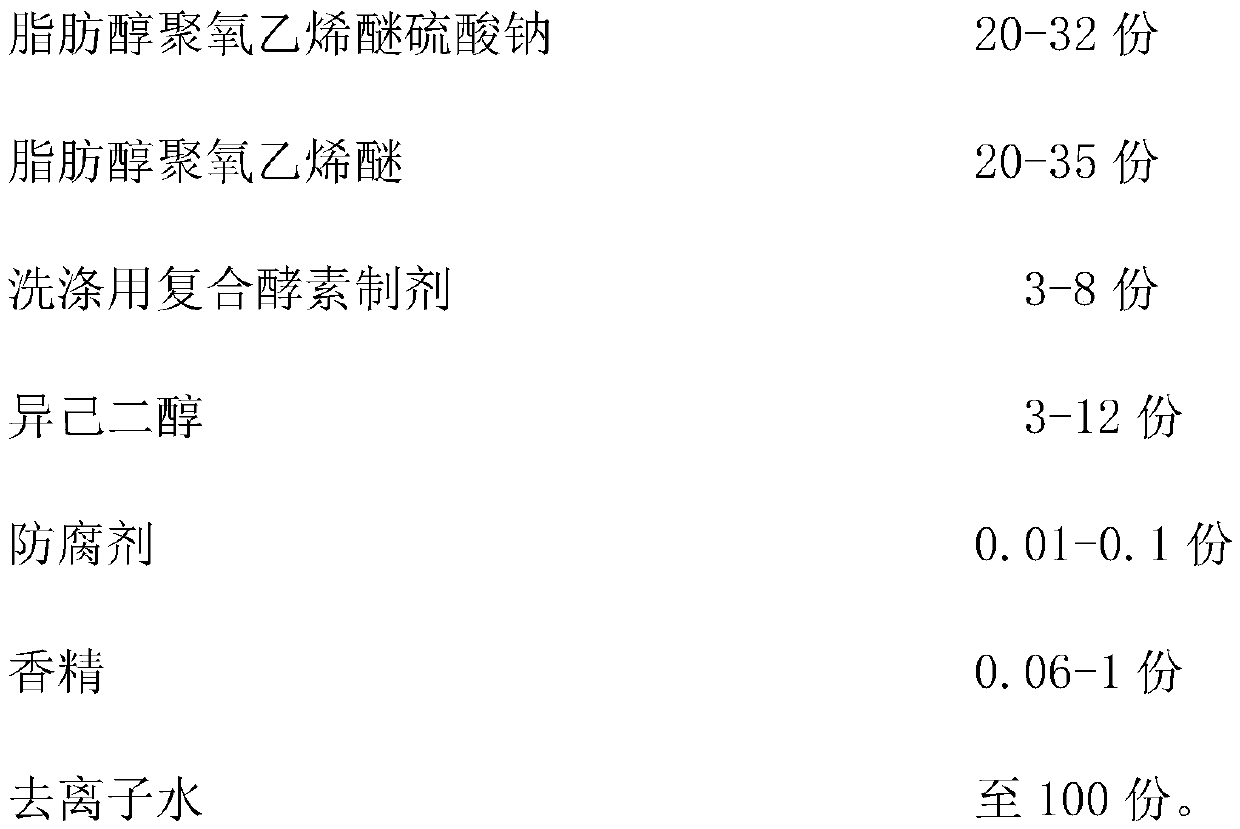

[0011] A high-concentration enzyme laundry detergent, consisting of the following components in parts by weight: 20 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 20 parts of fatty alcohol polyoxyethylene ether, 3 parts of composite enzyme preparation for washing, and 3 parts of isohexanediol , 0.01 parts of preservatives, 0.06 parts of essence, and 100 parts of deionized water.

Embodiment 2

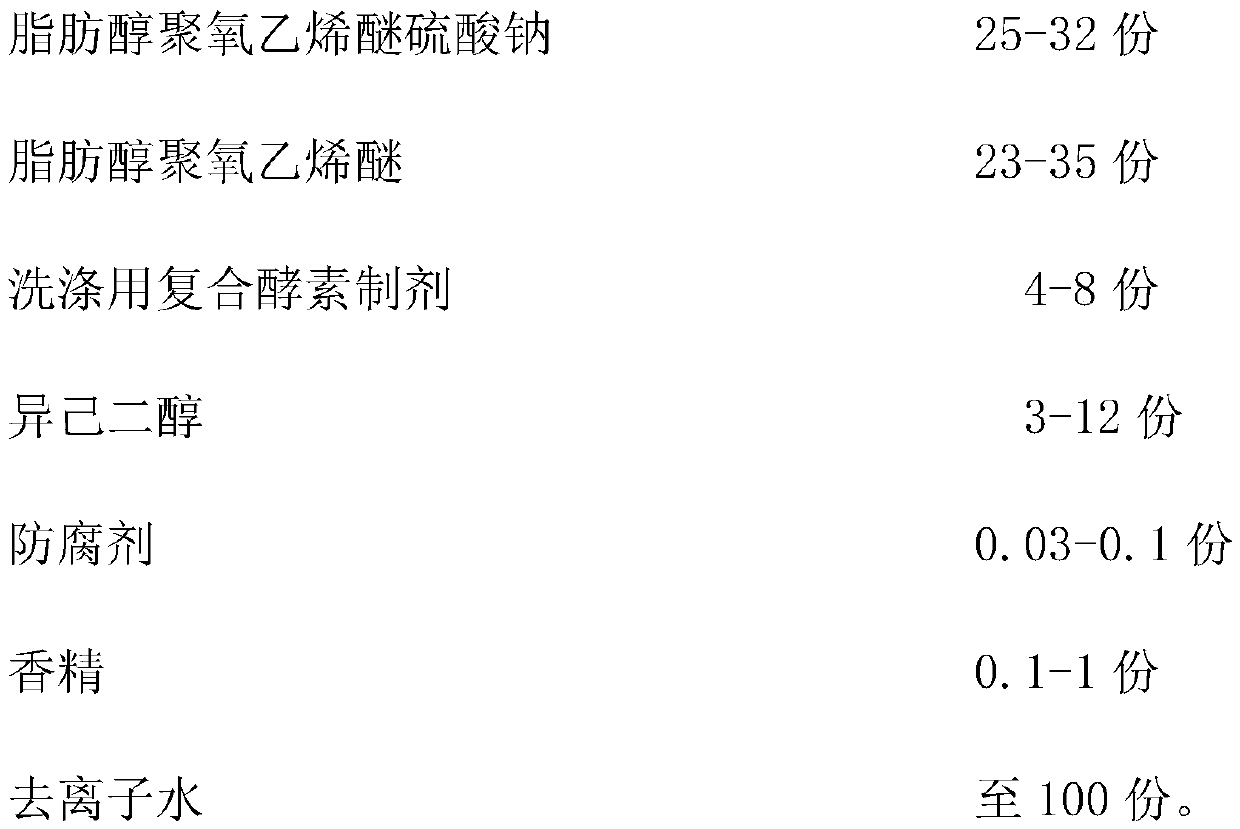

[0013] A high-concentration enzyme laundry detergent, consisting of the following components by weight: 27.5 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 32.5 parts of fatty alcohol polyoxyethylene ether, 5 parts of composite enzyme preparation for washing, and 5 parts of isohexanediol , 0.03 parts of preservatives, 0.1 parts of essence, and 100 parts of deionized water.

Embodiment 3

[0015] A high-concentration enzyme laundry detergent, consisting of the following components in parts by weight: 32 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 35 parts of fatty alcohol polyoxyethylene ether, 8 parts of composite enzyme preparation for washing, and 6 parts of isohexanediol , preservative 0.1 part, essence 1 part, deionized water to 100 parts.

[0016] The effective active matter of the laundry detergent of the present invention is as high as 60%. The main surfactant components are fatty alcohol polyoxyethylene ether sodium sulfate and fatty alcohol polyoxyethylene ether. The fatty alcohol polyoxyethylene ether sodium sulfate has strong decontamination ability and mild performance. The cost is low, and the fatty alcohol polyoxyethylene ether has a good degreasing effect. The laundry detergent produced by this formula does not need to change the ordinary lotion process, and isohexanediol is added as an auxiliary agent to give full play to the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com