Automatic container terminal stock yard landside automatic operation system and control method thereof

A technology for operating systems and containers, applied in safety devices, transportation and packaging, load suspension components, etc., can solve problems that require manual intervention and inspection, and achieve the effects of avoiding hidden dangers in production safety, saving operating time, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

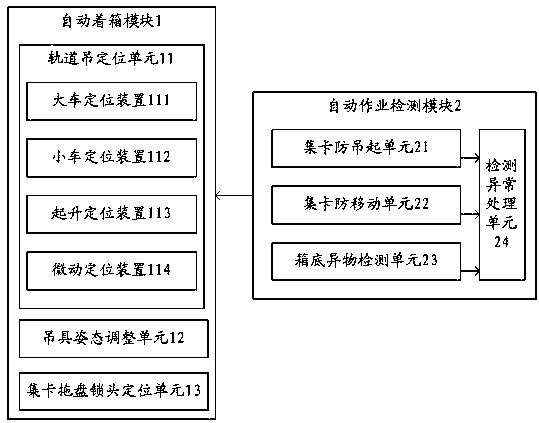

[0014] This application proposes an automatic operation system on the land side of the automated container terminal yard, which is suitable for automatic operation and automatic detection of receiving / delivering containers on the landside of the automated container terminal yard, and integrates the operation of encoder technology, magnetic ruler positioning technology, and laser scanning technology. , machine vision, image processing and other technologies to realize automatic and precise positioning of trucks and containers on the landside of the yard, automatic detection and alarm of abnormalities, without manual intervention in detection, and to improve the degree of automation; specific, such as figure 1 As shown, it includes an automatic box loading module 1 and an automatic operation detection module 2; the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com