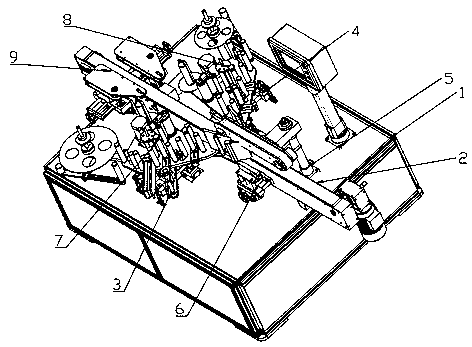

Intelligent diagonal labeling equipment

A labeling, diagonal technology, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems of low labeling accuracy, difficult production, and affect the appearance, and achieve high labeling accuracy, improve production efficiency, reduce costs and The effect of bad rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

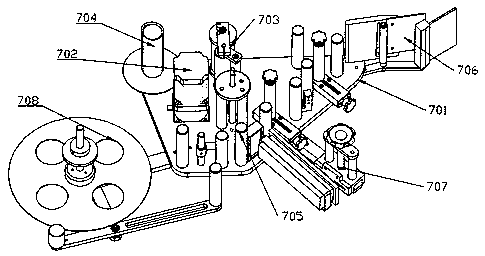

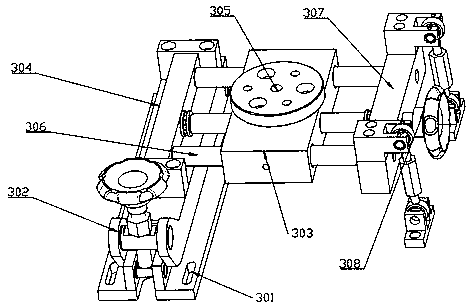

[0028] Embodiment 2 is different from the above in that the control mechanism is arranged parallel to the side of the upper pressing mechanism 5, and the control mechanism includes a touch screen base, a touch screen connecting rod, a touch screen and a control unit, and the touch screen base is vertically fixed on the On the workbench 1, the touch screen connecting rod is installed on the touch screen base, the touch screen is vertically fixed on the touch screen connecting rod, and the control unit is arranged in the touch screen.

[0029] The working principle of the present invention: first, the staff opens the device on the touch screen on the control mechanism, and then the products enter the conveyor belt in turn, and then the deceleration motor drives the driving wheel to rotate, and the driving wheel drives the conveyor belt to rotate, thereby driving the passive wheel to rotate, thereby driving the conveyor belt to convey products , when the product is conveyed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com