Membrane stripping device suitable for feeding of Z-shaped sheet membranes

A film material and film peeling technology, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems of film material bending, complicated grasping mechanism, film material made into roll material, etc., to overcome the problems of film material Bending deformation, the effect of overcoming production inefficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

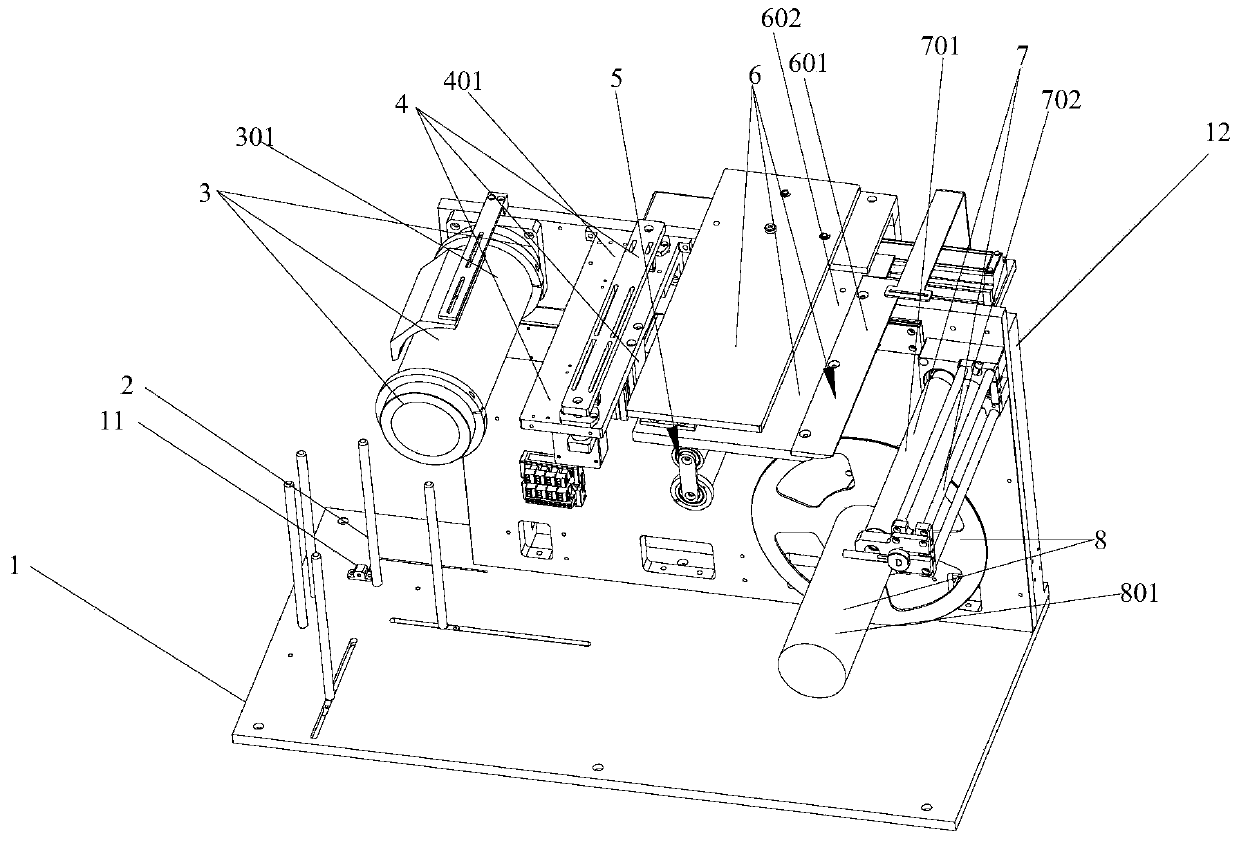

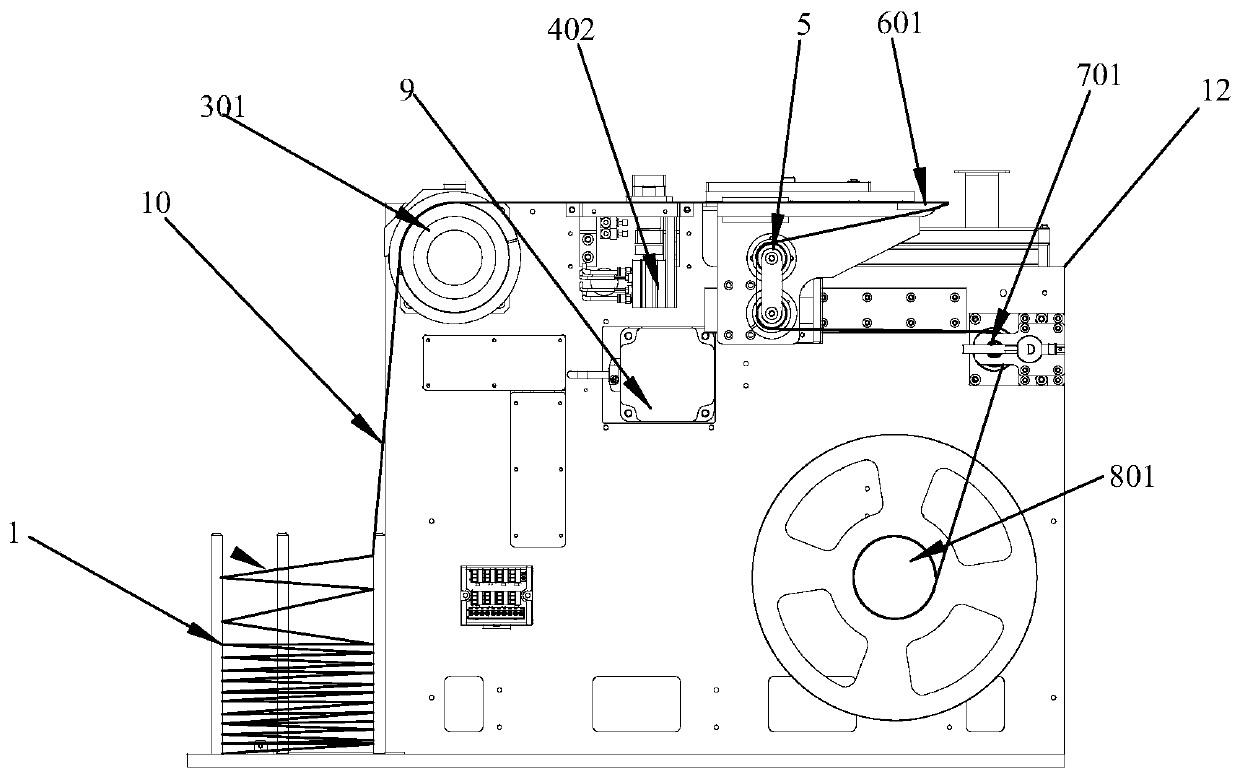

[0015] refer to Figure 1 to Figure 2 , the present invention provides a film stripping device suitable for Z-shaped sheet material feeding, including a base plate 1, a feed bin 2, and a fuselage 12; the feed bin 2 is arranged on one end of the base plate 1, wherein the material The X-axis and Y-axis on the warehouse 2 are placed on the waist-shaped groove of the bottom plate 1 and can slide along the waist-shaped groove. There is also a long waist-shaped hole in the direction of the X-axis and the direction of the Y-axis. The waist-shaped hole can be adapted to different sizes The film material of specification (such as 5 inches, 6 inches and other different specification film materials) is also provided with an optical fiber sensor 11 next to this silo 2, is used for detecting the position of zigzag sheet material film material; Said fuselage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com