Separation and purification equipment and method

An equipment and technology for purifying liquid, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of consuming large-power filter media, time-consuming and laborious cleaning of filter residues, slow filtration speed, etc. Increase the effect of gravity wash and ensure the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

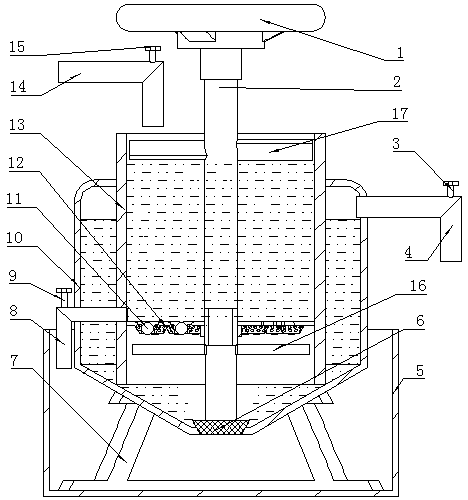

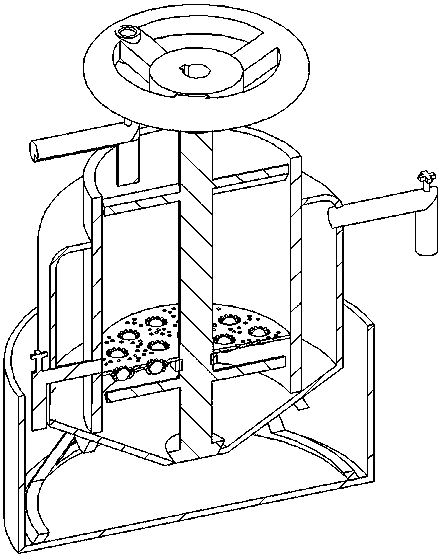

[0052] Such as figure 1 , figure 2 , image 3 , Image 6 , Figure 7 As shown, the outside of the mixed liquid barrel 13 is equipped with a purified liquid barrel 10 for containing pure liquid. The bottom plate of the purified liquid barrel 10 is installed on the upper part of the support 7, and the support 7 is located inside the collection barrel 5, which is a container with an upper opening.

[0053] The mixed liquid tank 13 is a vertically transparent structure, and the inner wall is equipped with a filter plate 12. The filter plate 12 divides the inner space of the mixed liquid tank into an upper purification area and a lower extension area. After the liquid is injected, the extension area below the filter plate 12 A closed air chamber 25 is formed between the upper part and the purified liquid barrel 10, and a plurality of inverted cone-shaped support holes 23 are arranged on the filter plate 12, and sinking balls 11 are installed in the inverted cone-shaped support ...

Embodiment 2

[0063] Such as Figure 8 As shown, the purified liquid barrel 10 is placed outside the mixed liquid barrel 13, and is connected with the mixed liquid barrel 13 through the connecting body 22. The sewage outlet is located at the bottom of the connecting body 22 and is coaxial with the axis of the mixed liquid barrel 13. The mixed liquid barrel 13 The bottom is installed on the support 7. All the other parts are the same as the first embodiment.

Embodiment 3

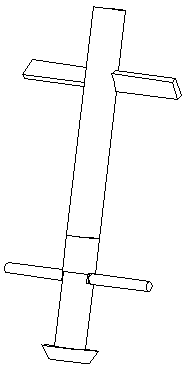

[0065] The positional relationship and setting method of the mixed liquid tank, the purified liquid tank, the collecting tank, the liquid inlet valve, the liquid discharge valve and the recoil valve in this embodiment are the same as those in the first embodiment, the difference is that there is no nut installed on the lower part of the filter plate, and there is no Set the axis.

[0066] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the sewage outlet is connected to the installation plug body 6, the upper end of the plug body 6 is connected to the first pull rope 20, the other end of the first pull rope 20 is connected to the part of the sinker ball 11 located below the inverted tapered support hole, and the sinker ball 11 is located in the inverted taper hole. The part above the tapered support hole is connected with the second stay rope 19, and the other end of the second stay rope 19 is connected with the floating ball 18 rising and falling with the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com