Multi-function duct for dry scrubber system

A multifunctional, pipeline technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., to achieve the effect of excellent structural simplification, improved equipment pressure management, and significant equipment pressure management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

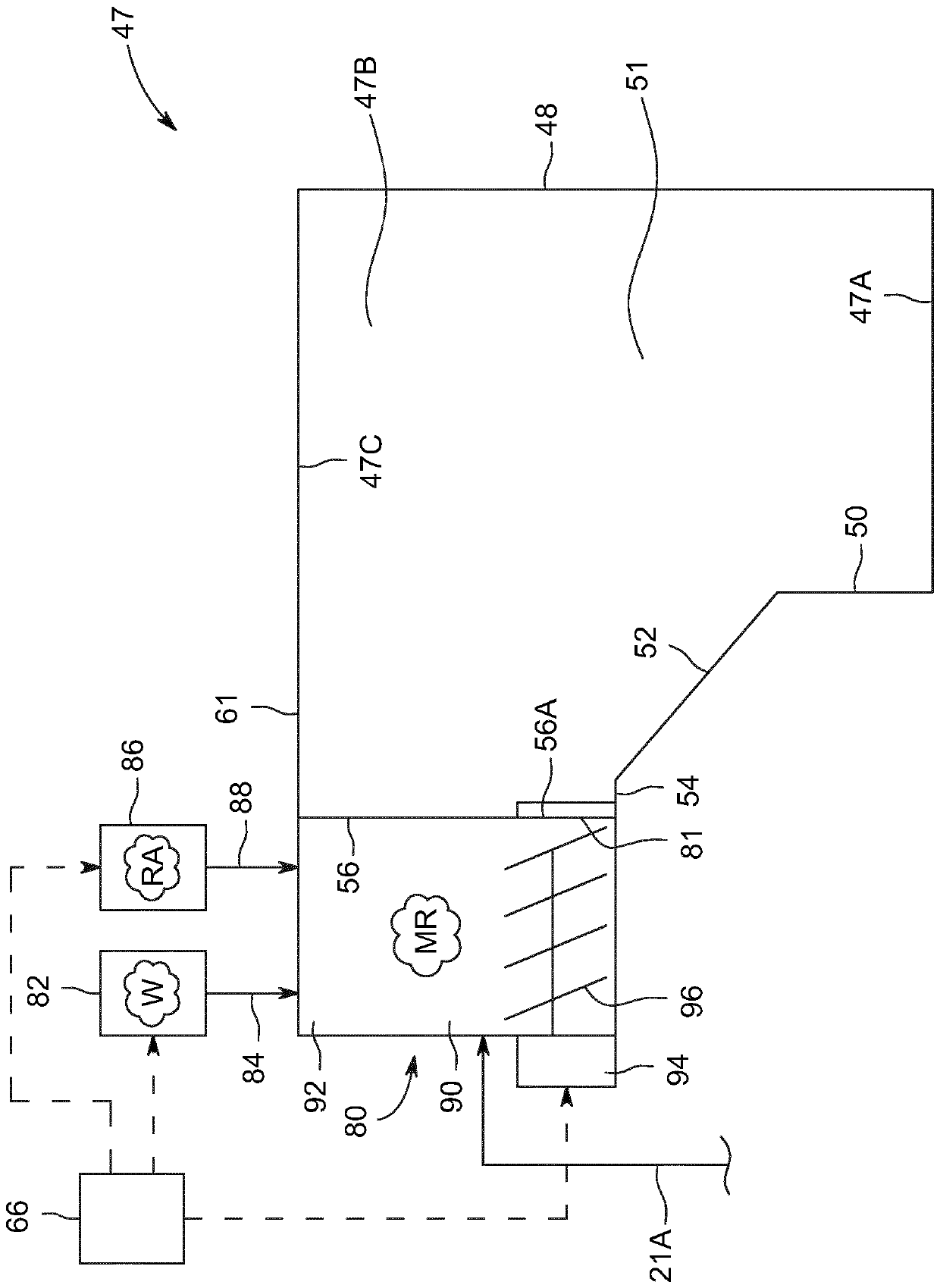

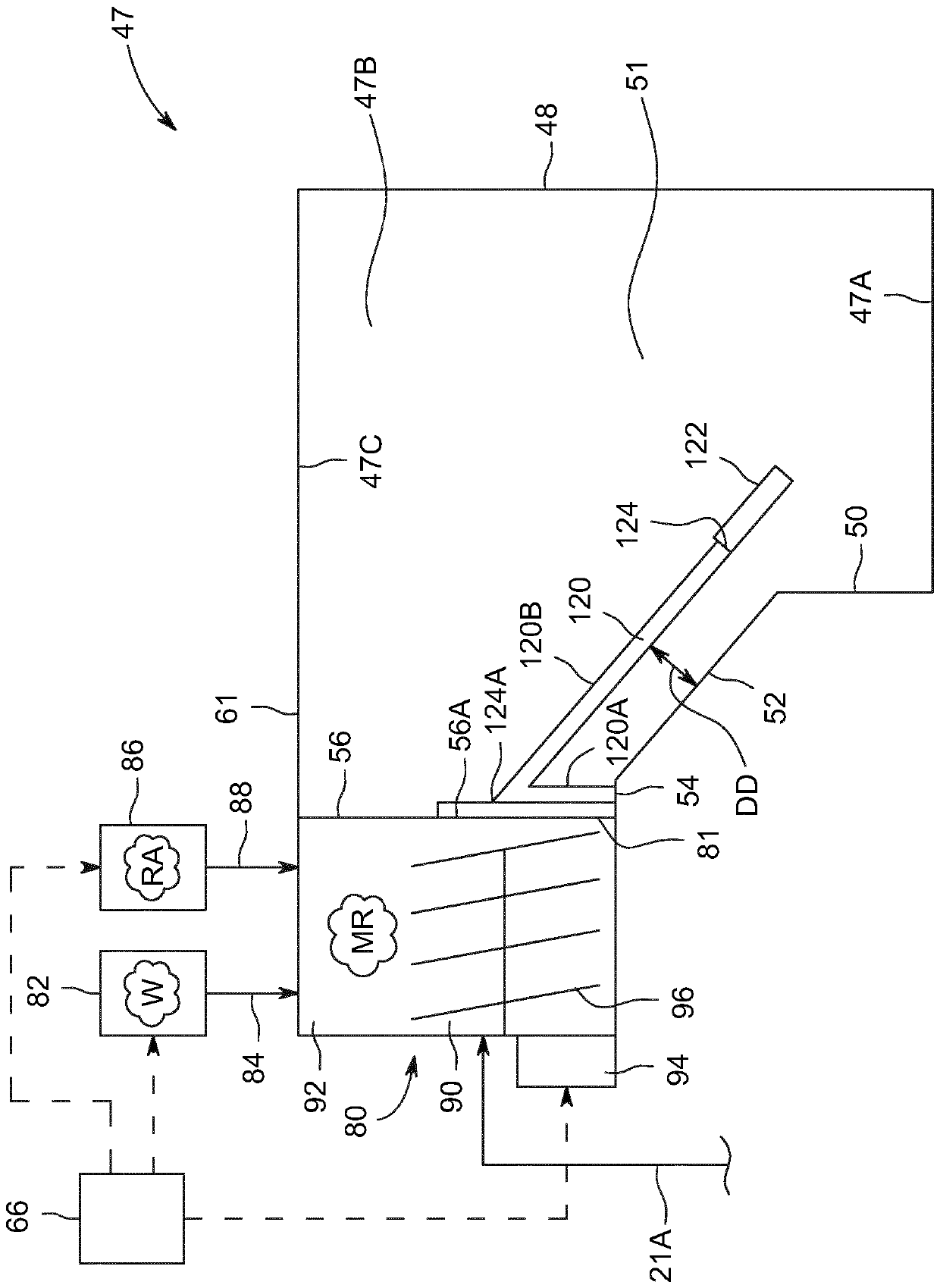

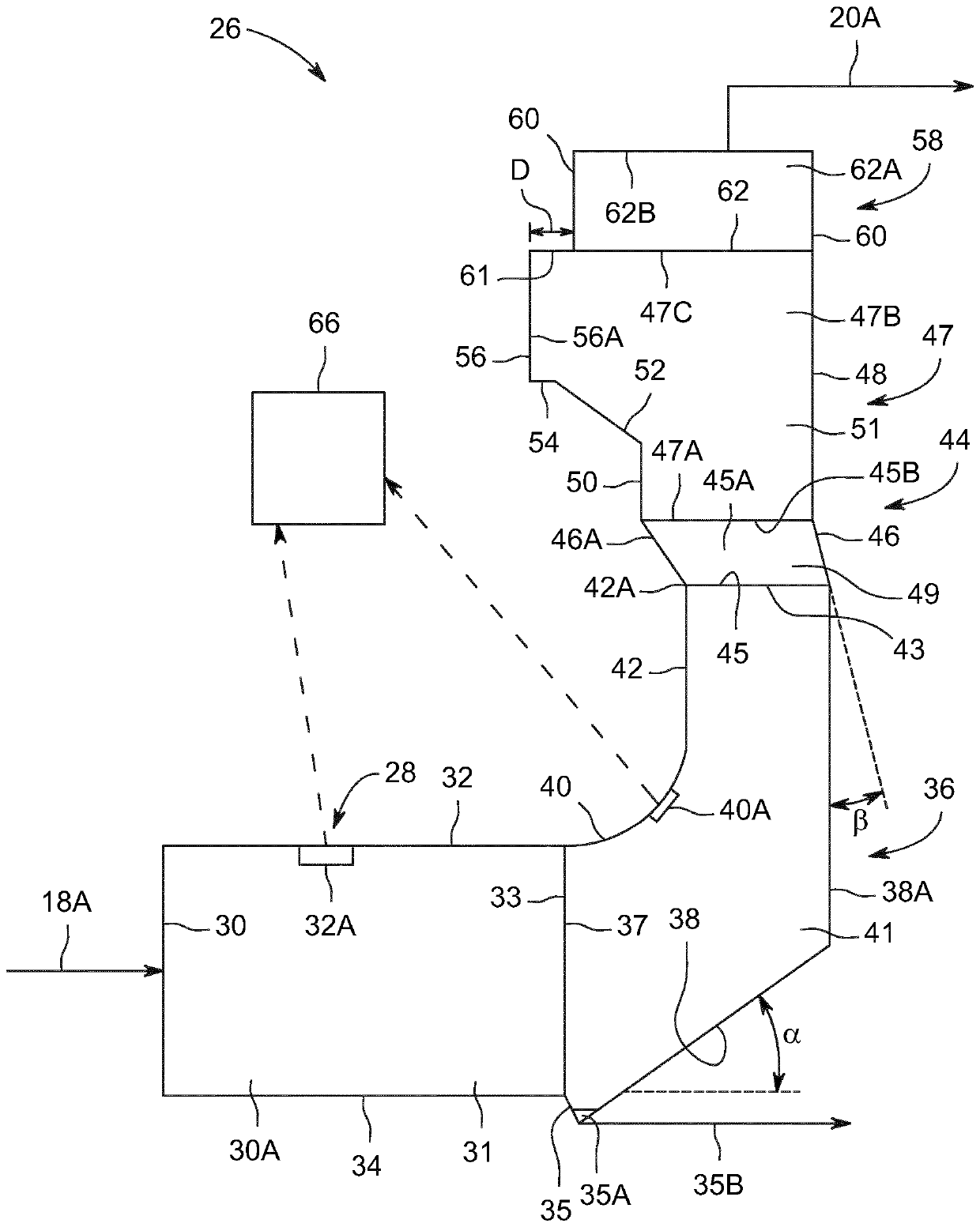

[0028] refer to figure 1 , there is disclosed herein an apparatus 10, such as a power plant or industrial plant, that includes a combustion unit 12, such as, for example, a boiler unit that produces steam. The combustion unit 12 can be supplied with at least one oxygen-containing gas G (for example, air, O 2 gas or including O 2 gas of gas). Likewise, the combustion unit 12 may be supplied with carbonaceous fuel F from the fuel supply 16 via a fluidly connected fuel conduit 16A for combustion of the fuel F within the combustion unit 12 . The fuel F supplied to the combustion unit 12 is preferably a fossil fuel such as, for example, coal, oil or natural gas. In addition to steam, flue gas FG is produced when the fuel F is burned in the combustion unit 12 . The steam produced by the combustion of the fuel F may be sent to a turbine (not shown) for use in power generation, or for other uses such as, for example, district heating, preheating of the combustion unit 12, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com