Mine barrel monitoring method

A mine and barrel edge technology, which is applied in the field of underground monitoring, can solve the problems of untimely monitoring accuracy easily affected by the external environment and cumbersomeness, and achieve the effects of diversified monitoring data, multi-directional monitoring, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] It should be noted that the "mine shaft" referred to in the embodiments of the present invention all refers to mine shaft shafts.

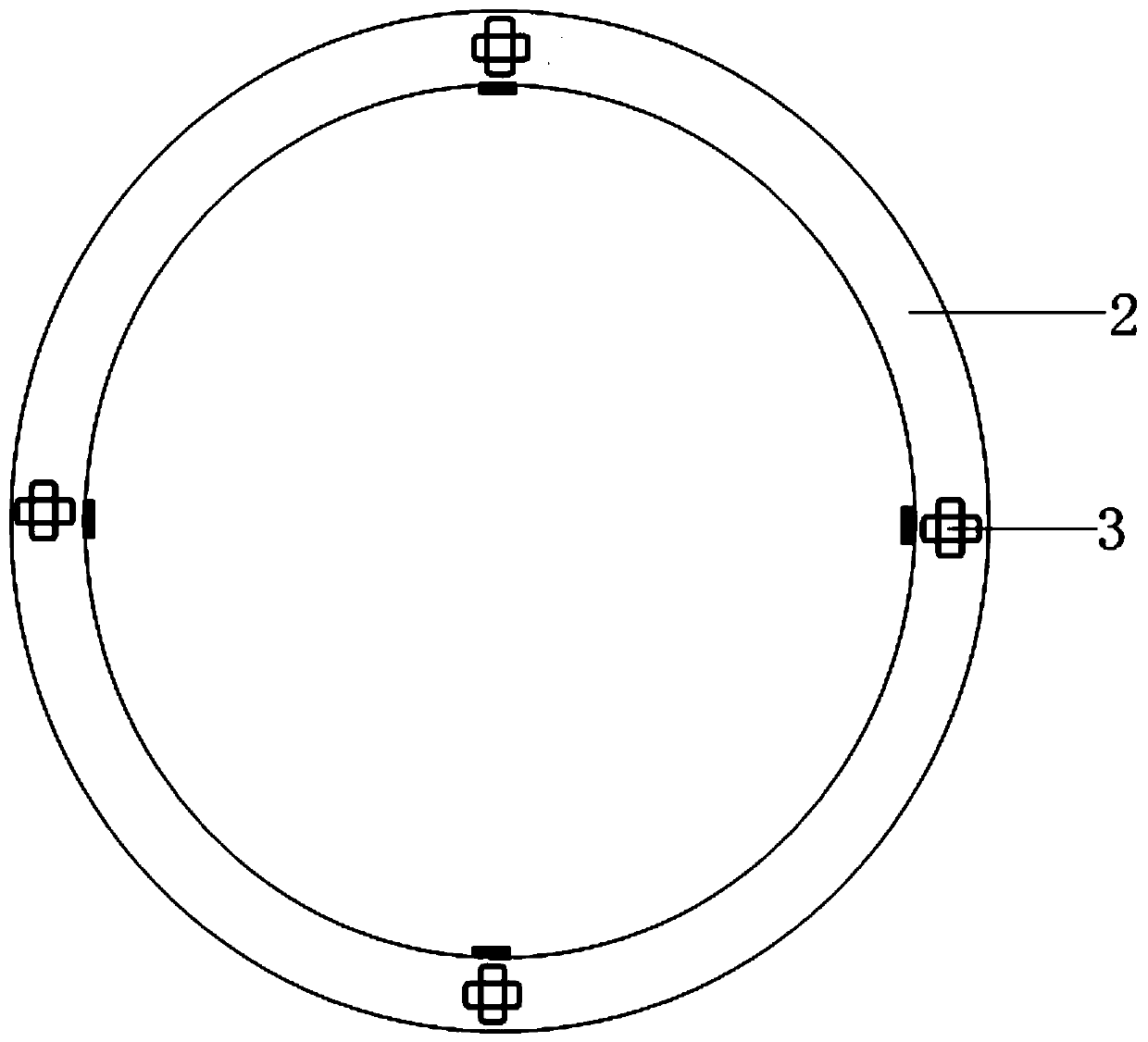

[0044] An embodiment of the present invention provides a mine shaft monitoring method. The inner wall of the mine shaft is provided with multiple rings of annular pressure relief grooves at intervals along the axial direction. The mine shaft monitoring method includes: installing an annular force transmission medium in the annular pressure relief groove , and install a plurality of fiber grating strain sensors on the wall of the annular installation groove formed by the annular force transmission medium and the annular pressure relief groove.

[0045] Obtain the strain signal of the mine shaft in real time through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com