Thermal insulation and energy-saving prefabricated house and assembly method thereof

A prefabricated and housing technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of low connection strength, unsatisfactory heat insulation effect, poor windproof and rainproof performance, etc., to achieve improved structural strength, good structural strength, The effect of increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

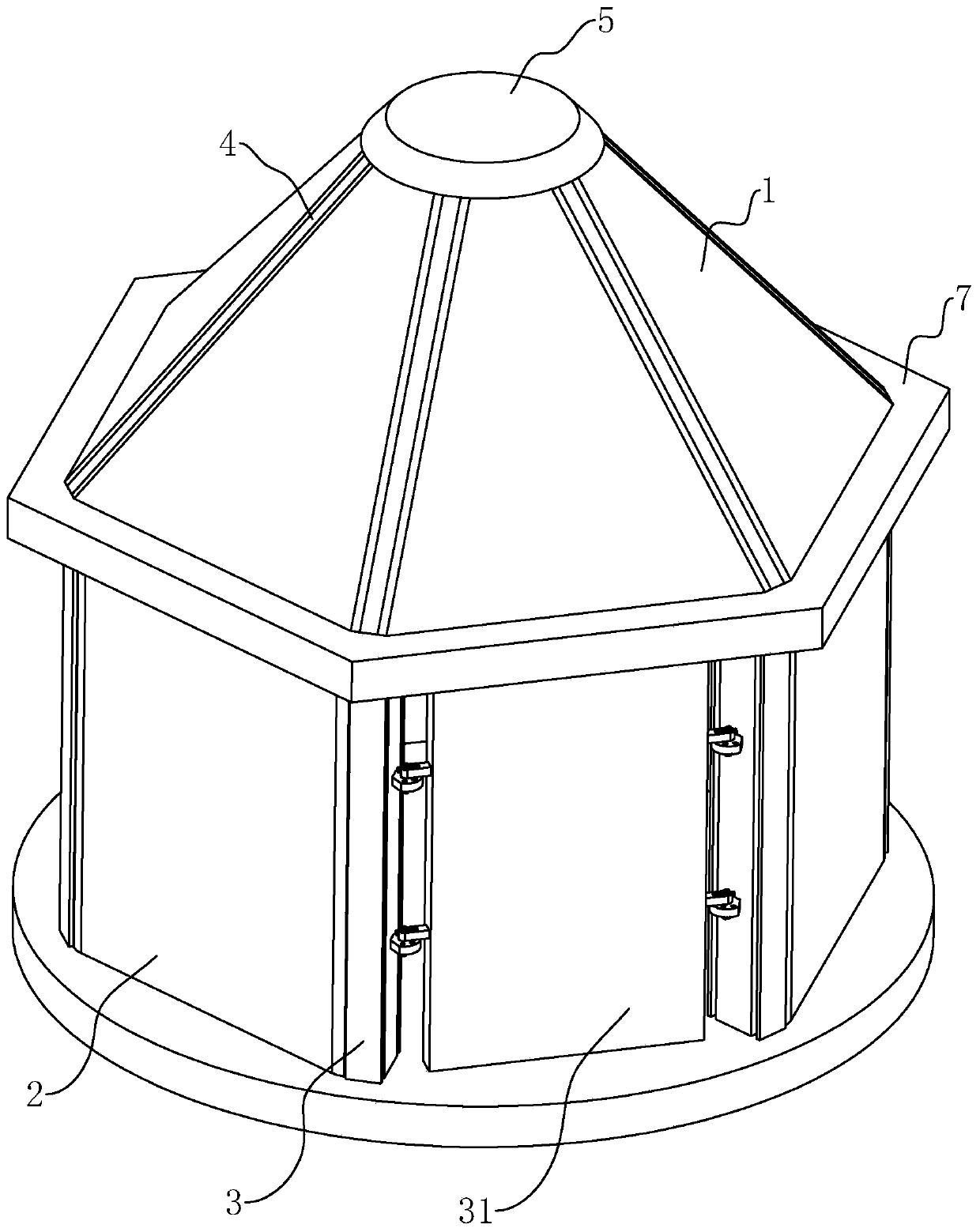

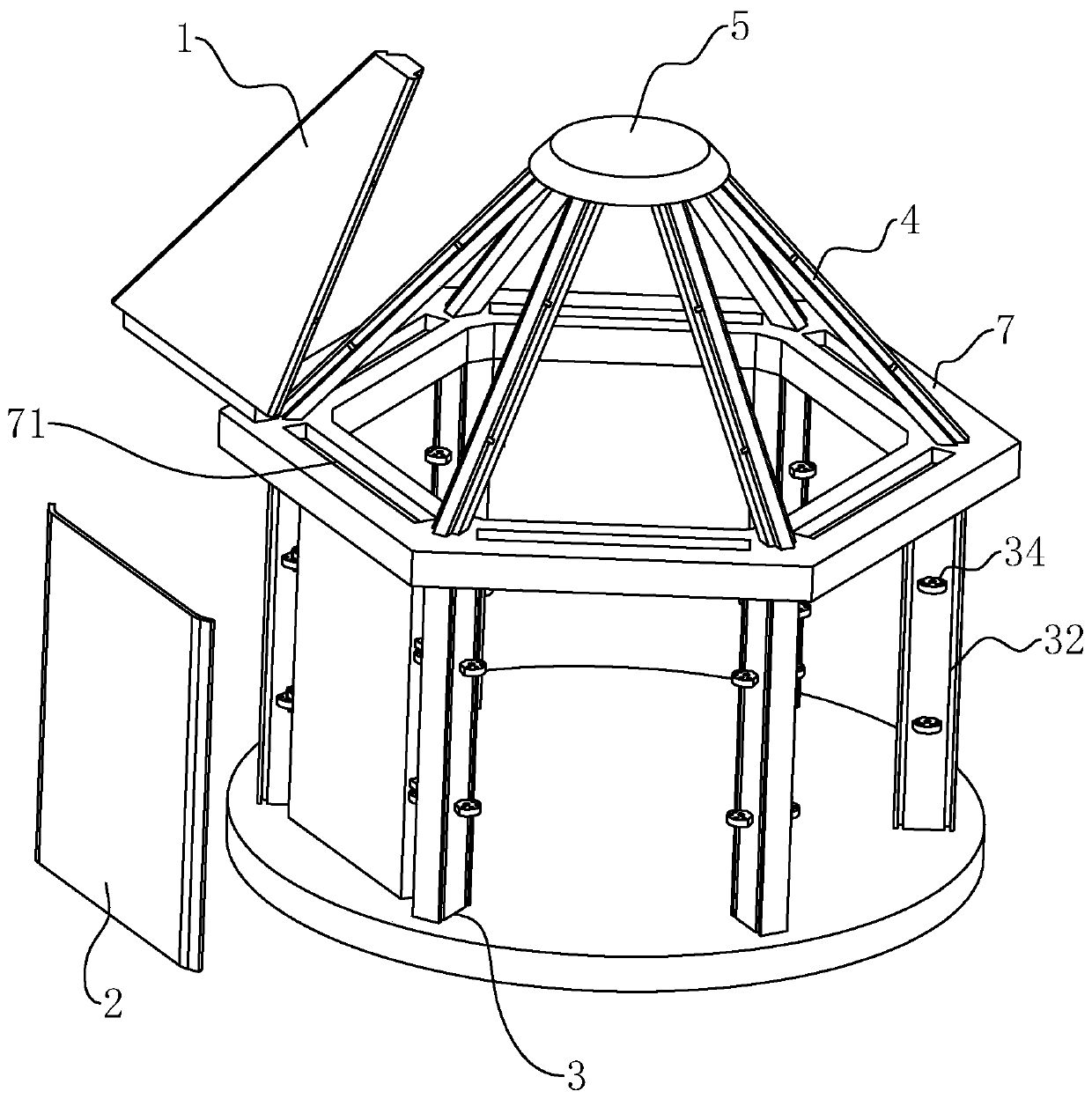

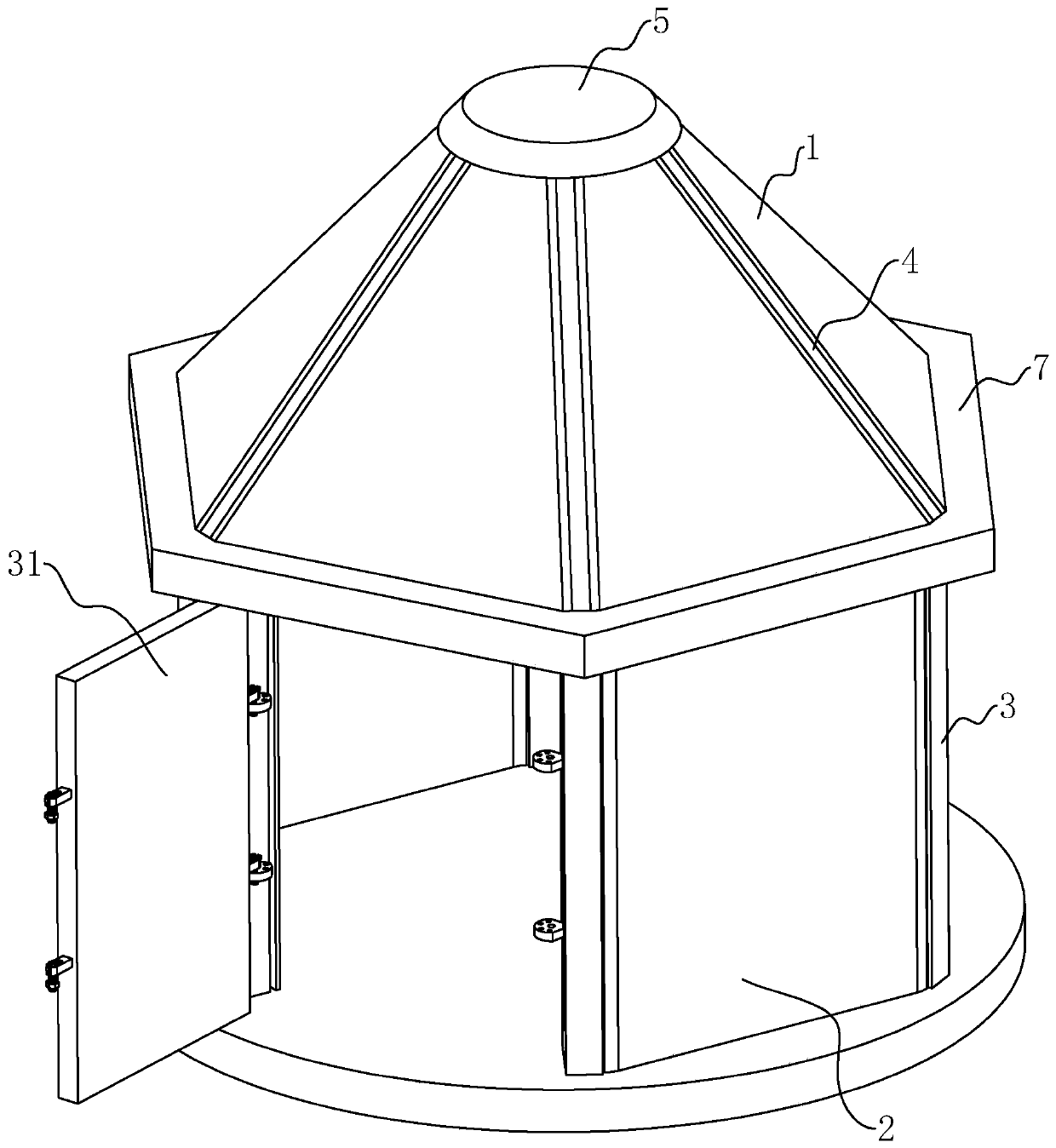

[0044] Embodiment 1: A kind of thermal insulation and energy-saving prefabricated house, such as figure 1 and figure 2 As shown, it includes a building frame 3 formed by interconnecting multiple building units 31 , and wall panels 2 and formwork roof panels 1 respectively arranged on the building frame 3 .

[0045] Such as Figure 4 , Figure 5 and Figure 6 As shown, wherein, the construction unit 31 includes a load-bearing column 32, a reinforcing plate 33, a fixed plate 34 fixedly arranged on both sides of the load-bearing column 32, a connecting plate 35 fixedly arranged on both sides of the reinforced plate 33, and a fixed plate arranged on the fixed plate 34 and the connecting plate 35 between the fixed rod 36; the connecting plate 35 is provided with a fixing hole 351 for the fixing rod 36 to pass through, and the connecting plate 35 is provided with a square hole 352, and the square hole 352 is located at the fixing hole 351 toward the reinforcement One side of pl...

Embodiment 2

[0056] Embodiment 2: A method for assembling an insulated and energy-saving prefabricated house, comprising the following steps:

[0057] S1. Assembling the building frame 3: install the connecting plate 35 in the building unit 31 on the fixing plate 34, and connect it through the rotation of the fixing rod 36, and adjust the reinforcing plate between adjacent building units 31 according to the size of the prefabricated house 33, and by inserting the locking bar 37 into the square hole 352, the load-bearing beam 4 is fixed on the re-lift, and then the load-bearing beam 4 is built on the load-bearing column 32, so that the building units 31 are sequentially connected to form a building frame 3.

[0058] S2. Installation of wall panel 2: install the inner wall insulation board 21 and the outer wall insulation board 22 on both sides of the reinforcement board 33 respectively, and connect them with the load-bearing column 32 to form a ring-sealed prefabricated house.

[0059] S3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com