Retaining and anti-loosening gasket, nut and bolt special for high-speed railway track

A technology of railway track and anti-loosening gasket, which is applied in the direction of tracks, roads, fixed rails, etc. It can solve the problems of the performance and strength of the elastic strip, the difficulty in preventing back and forth and anti-loosening, and the small contact area between the elastic strip and the gasket. , to achieve the effect of ensuring integrity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

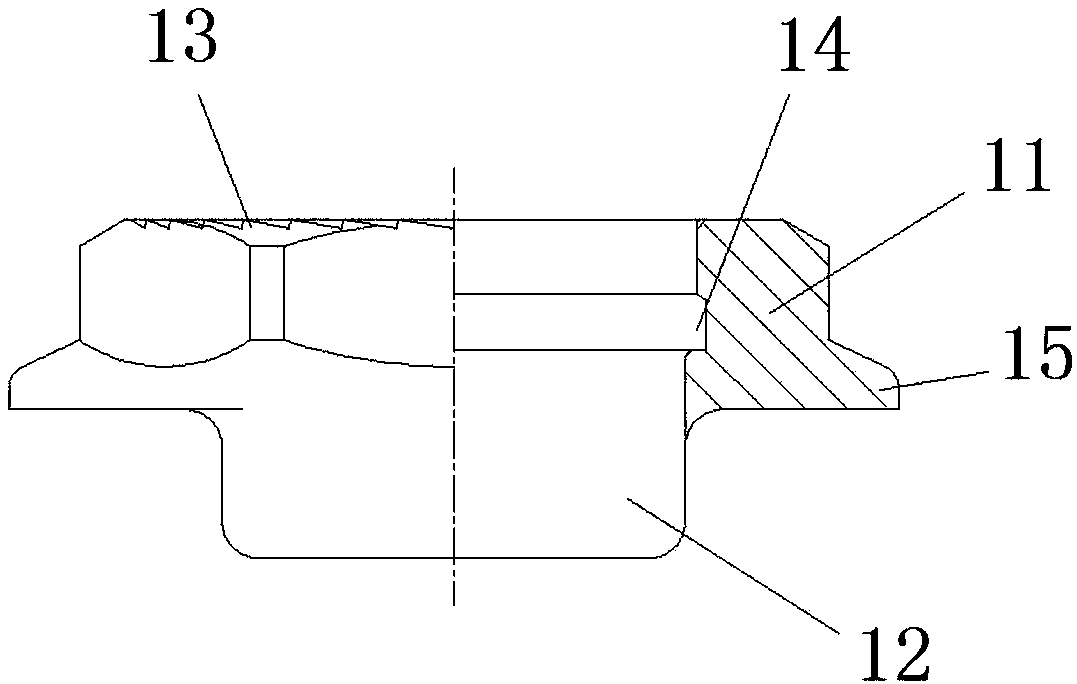

[0037] see Figure 1 to Figure 3 ,and Figure 8 , Figure 9, This embodiment provides an anti-retreat and anti-loosening washer. The anti-retraction and anti-loosening washer includes a washer body 11 . In order to apply the torque wrench-driven tensioner to the anti-retraction and anti-loosening gasket, the outer contour of the gasket body 11 can be designed as a regular hexagon or other regular polygons. The lower end surface of the gasket body 11 is provided with a first fixed protruding structure 12, and the first fixed protruding structure 12 is used to snap into the gap between the two limbs of the spring bar and prevent the spacer body 11 from colliding with the elastic bar. Rotation; the upper surface of the washer body 11 is provided with a second fixing protruding structure 13, and the second fixing protruding structure 13 is used to prevent relative rotation between the washer body 11 and the nut or bolt after being fastened.

[0038] The anti-retraction and ant...

Embodiment 2

[0045] see Figure 4 and Figure 5 , this embodiment provides a anti-retraction locknut. The anti-retreat and anti-loosening nut includes a nut body 21, and the lower end surface of the nut body 21 is provided with a third fixed protrusion structure 22, and the third fixed protrusion structure 22 is used to prevent the nut body 21 and the washer from being tightened. Relative rotation occurs after solidification; the lower end surface of the nut body 21 is also provided with a plug-in structure 23, and the plug-in structure 23 is used for riveting into the socket structure 14 provided on the through hole of the washer.

[0046] The anti-retreat locknut is used in conjunction with the anti-retreat and anti-loosening washer described in Embodiment 1 as a fastener, and is used to connect and fix the rail with the lower structure (sleeper rail, backing plate) in conjunction with the elastic strip. After the fastener is tightened, due to the interaction between the third fixed pr...

Embodiment 3

[0051] see Figure 6 and Figure 7 , this embodiment provides a back and forth anti-loosening bolt. The anti-retraction and anti-loosening bolts include a bolt body 31, the lower end surface of the bolt body 31 is provided with a fourth fixed protrusion structure 32, and the fourth fixed protrusion structure 32 is used to prevent the bolt body 31 and the gasket from being tightened. Relative rotation occurs after solidification.

[0052] The anti-retreat and anti-loosening bolts are used in conjunction with the anti-retreat and anti-loosening washers described in Embodiment 1 as fasteners, and are used to connect and fix the rails with the lower structure (sleeper rails, backing plates) in conjunction with elastic strips. After the fastener is tightened, due to the interaction between the fourth fixed protrusion structure 32 and the second fixed protrusion structure 13, the anti-retreat and anti-loosening bolt and the anti-retreat and anti-loosening gasket cannot rotate rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com