Device and method for preparing sulfur by coal gasification in conjunction with calcium sulfate calcination and carbon thermal reduction

A technology of coal gasification and calcium sulfate, applied in the direction of sulfur preparation/purification, which can solve the problems of low utilization rate of raw materials, energy consumption needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

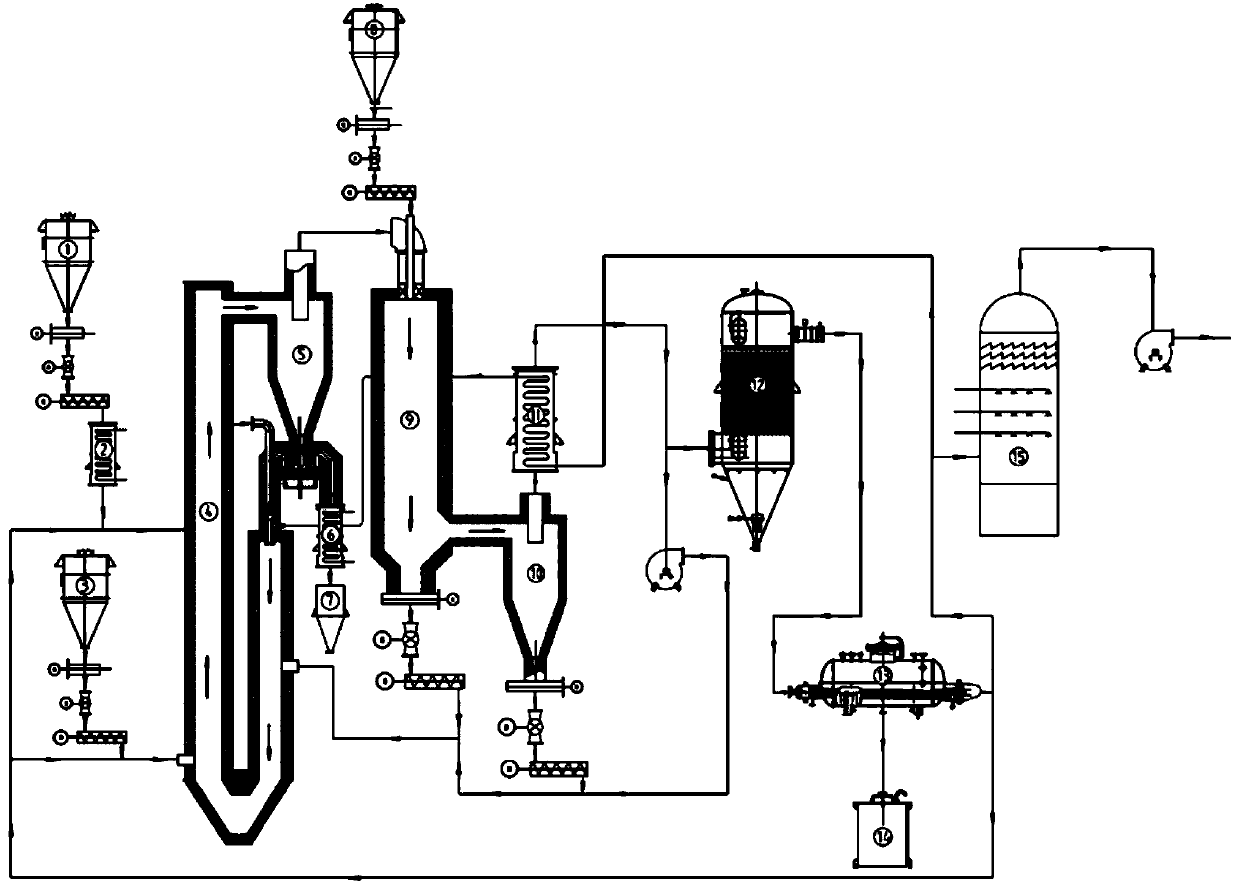

[0068] A device for preparing sulfur by coal gasification combined with calcium sulfate calcination and carbon thermal reduction, including: U-shaped furnace 4, high temperature separator I (5), calcium sulfate storage bin 1, carbon material storage bin I (3), carbon thermal reduction Tower 9, high-temperature separator II (10), reheater 11, dedusting device 12, sulfur recovery device 13, sulfur storage tank 14; the U-shaped furnace 4 is divided into a calcination section on the left and a coal gasification section on the right. The calcination section on the left side is connected to the calcium sulfate storage bin 1 and the carbon material storage bin I (3), and the upper outlet of the coal gasification section on the right side of the U-shaped furnace 4 is connected to the inlet of the high-temperature separator I (5). The bottom material outlet of the separator I (5) is connected to the coal gasification section on the right side of the U-shaped furnace 4 and the calcium ox...

Embodiment 2

[0073] A device for preparing sulfur by coal gasification combined with calcium sulfate calcination and carbon thermal reduction, including: U-shaped furnace 4, high temperature separator I (5), calcium sulfate storage bin 1, carbon material storage bin I (3), carbon thermal reduction Tower 9, high-temperature separator II (10), reheater 11, dedusting device 12, sulfur recovery device 13, sulfur storage tank 14; the U-shaped furnace 4 is divided into a calcination section on the left and a coal gasification section on the right. The calcination section on the left side is connected to the calcium sulfate storage bin 1 and the carbon material storage bin I (3), and the upper outlet of the coal gasification section on the right side of the U-shaped furnace 4 is connected to the inlet of the high-temperature separator I (5). The bottom material outlet of the separator I (5) is connected to the coal gasification section on the right side of the U-shaped furnace 4 and the calcium ox...

Embodiment 3

[0077] A device for preparing sulfur by coal gasification combined with calcium sulfate calcination and carbon thermal reduction, including: U-shaped furnace 4, high temperature separator I (5), calcium sulfate storage bin 1, carbon material storage bin I (3), carbon thermal reduction Tower 9, high-temperature separator II (10), reheater 11, dedusting device 12, sulfur recovery device 13, sulfur storage tank 14; the U-shaped furnace 4 is divided into a calcination section on the left and a coal gasification section on the right. The calcination section on the left side is connected to the calcium sulfate storage bin 1 and the carbon material storage bin I (3), and the upper outlet of the coal gasification section on the right side of the U-shaped furnace 4 is connected to the inlet of the high-temperature separator I (5). The bottom material outlet of the separator I (5) is connected to the coal gasification section on the right side of the U-shaped furnace 4 and the calcium ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com