Shower nozzle feeding device

A nozzle and shaft installation technology, which is applied in the field of mechanical devices, can solve the problem that the upper nozzle device cannot work stably and reliably, and achieves the effects of high speed, reduced pollution sources and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

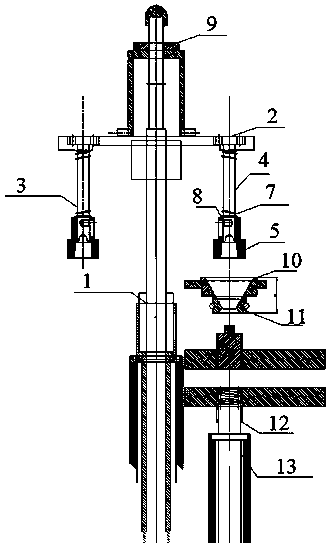

[0019] as attached figure 1 As shown, an upper nozzle device includes a rotating shaft 1, a fixed turntable 2, an up and down moving shaft 3, a capping shaft 4, a cap fixing module 5, an upper positioning 10, a lower positioning 11, a bottle ejector sleeve 12, and a bottle upper and lower shaft 13. The fixed turntable 2 is installed on the rotating shaft 1, and the up and down moving shaft 3 is installed on one side of the fixed turntable 2 for adjusting the height of the fixed turntable 2. The gland shaft 4 is installed on the other side of the fixed turntable 2, and the cover is fixed The module 5 is installed under the capping shaft 4, and the return spring 7 is installed above the capping module 5. The upper positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com