Bobbin winder used for glass fiber active winding

An active winding and glass fiber technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of machine shutdown economy, interference winder, yarn waste, etc., and reduce labor intensity , to avoid stripping and random yarn, and to reduce the effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

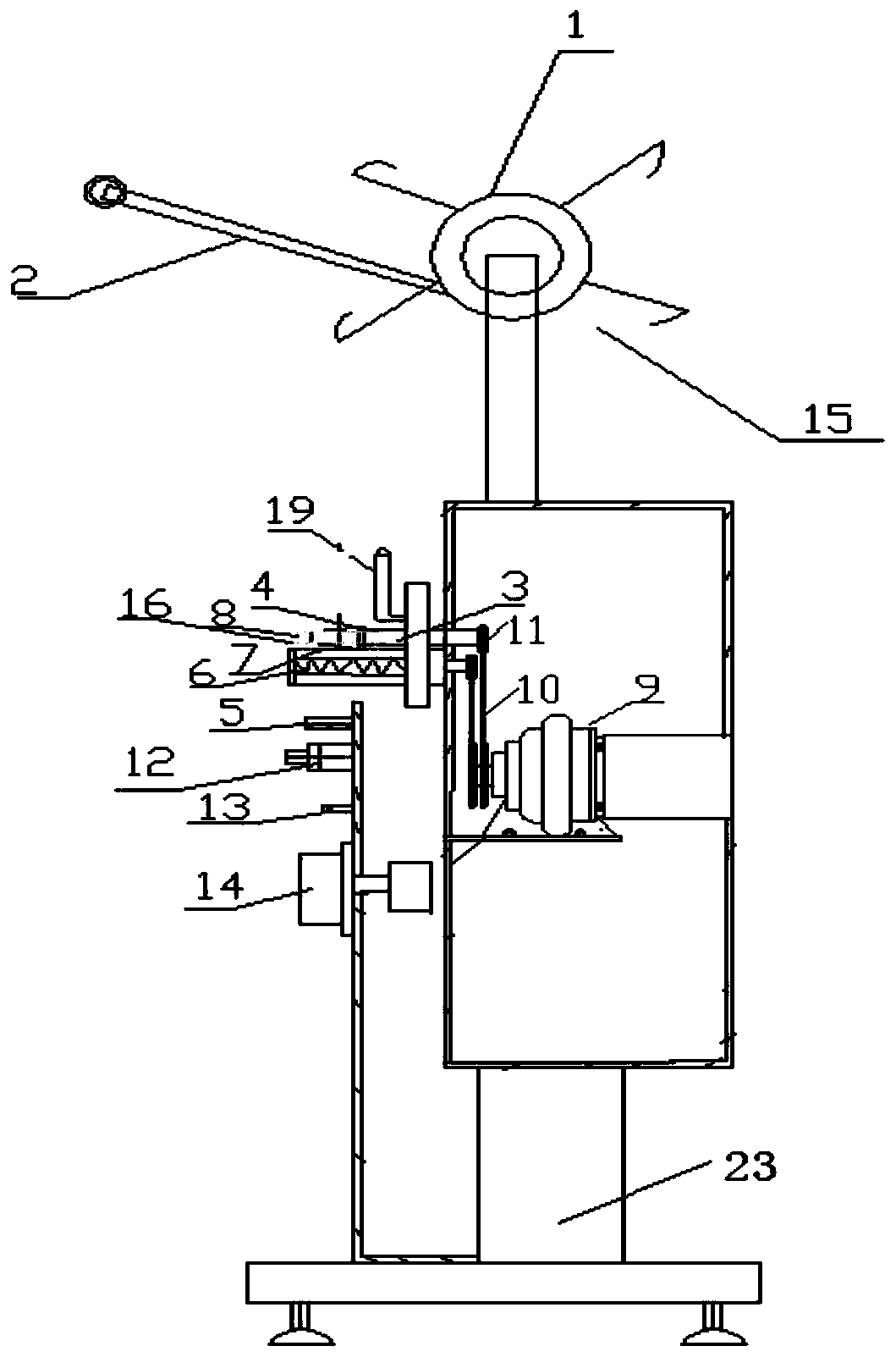

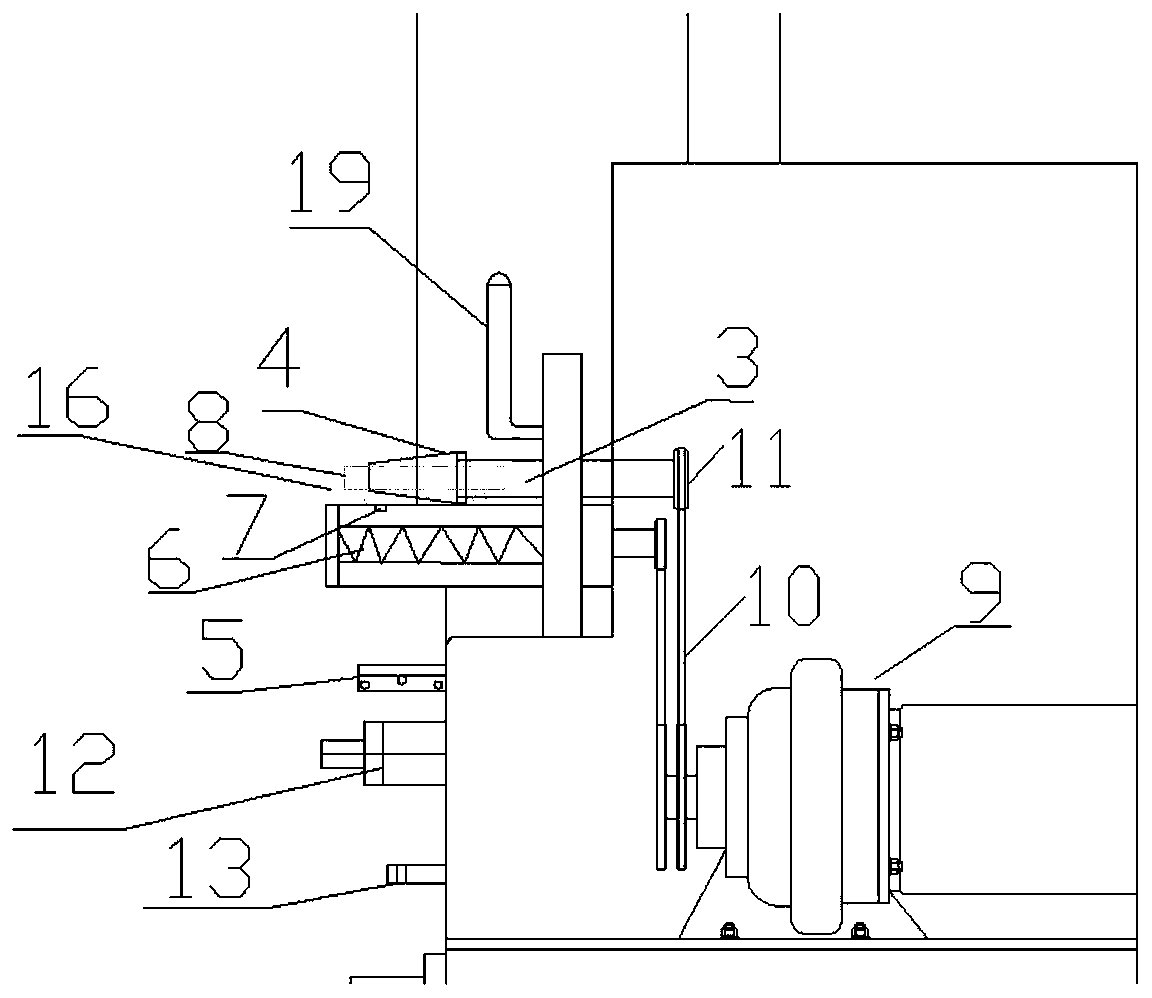

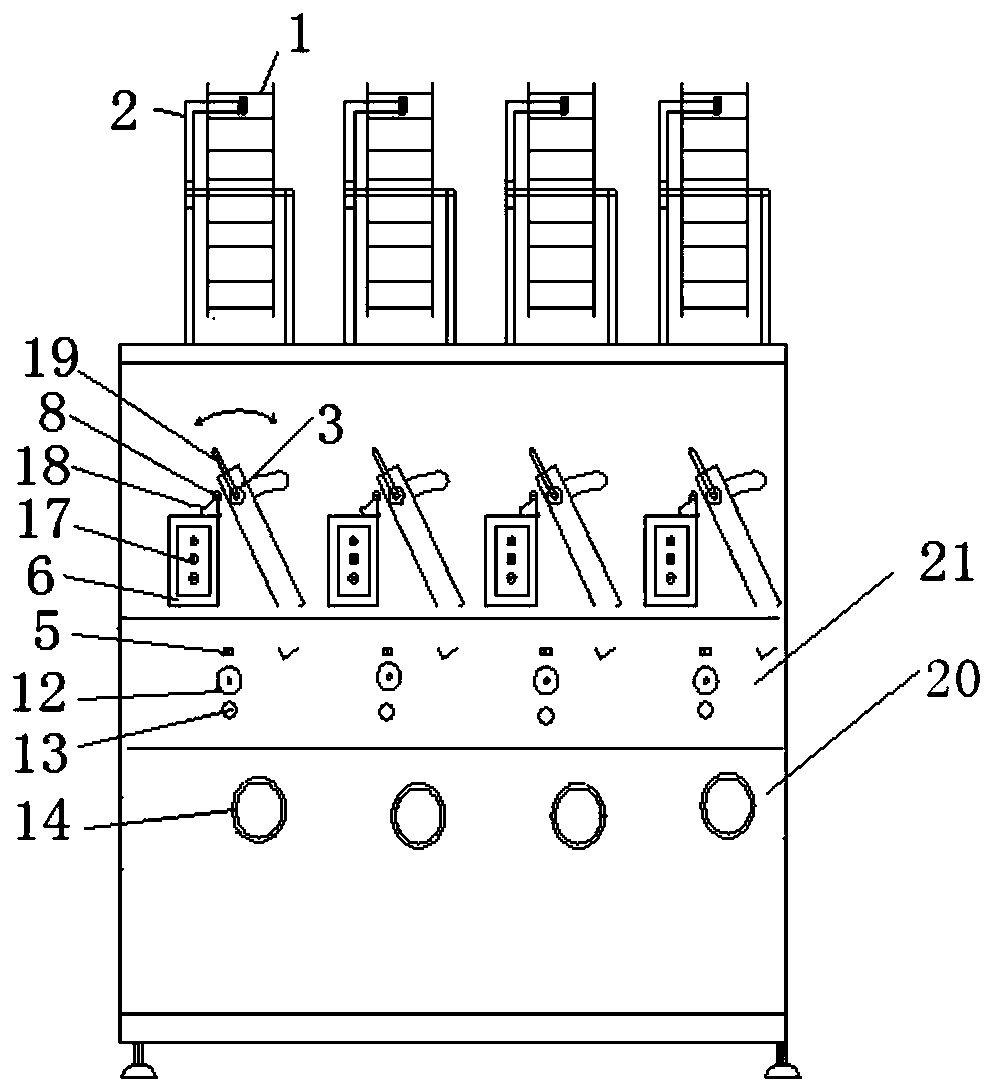

[0027] This embodiment is a winding winder for glass fiber, including four groups of creel assemblies 15, four crimping mechanisms 16, four tensioners 12, four overfeeding wheels 14, a base 24 and a cabinet 22 . Wherein, the chassis 22 is fixed on the upper surface of the base 24 through a chassis bracket.

[0028] The four groups of creel assemblies 15 are located at the upper end of the cabinet 22 . The motors 9 of each group of creel assemblies are respectively arranged in the said cabinet. Two synchronous pulleys are installed on the output shafts of each of the motors, and the two synchronous belts are sleeved on the synchronous pulleys, and the other ends of each of the synchronous belts are respectively connected to the creel assemblies of each group. The first synchronous pulley 11 and the second synchronous pulley 25 are connected; the axles of each of the first synchronous pulley and the second synchronous pulley pass through the panel 20 of the cabinet. The four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com