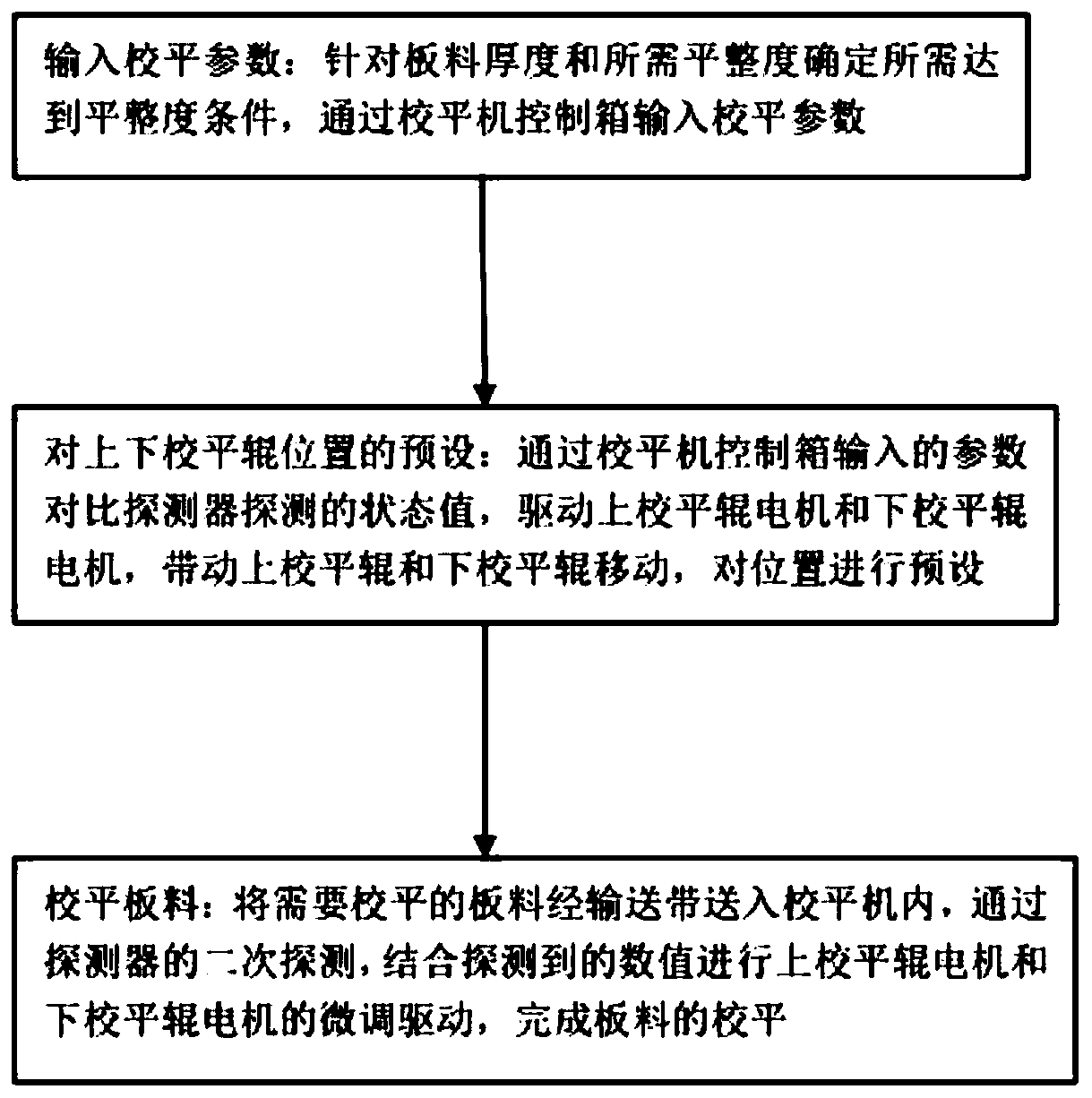

Intelligent flattening machine and flattening method thereof

A leveling machine and leveling technology, which is applied in the field of leveling machines, can solve problems such as low efficiency and inability to automate production, and achieve the effects of good adjustment comprehensiveness, labor saving, and good consistency in the adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

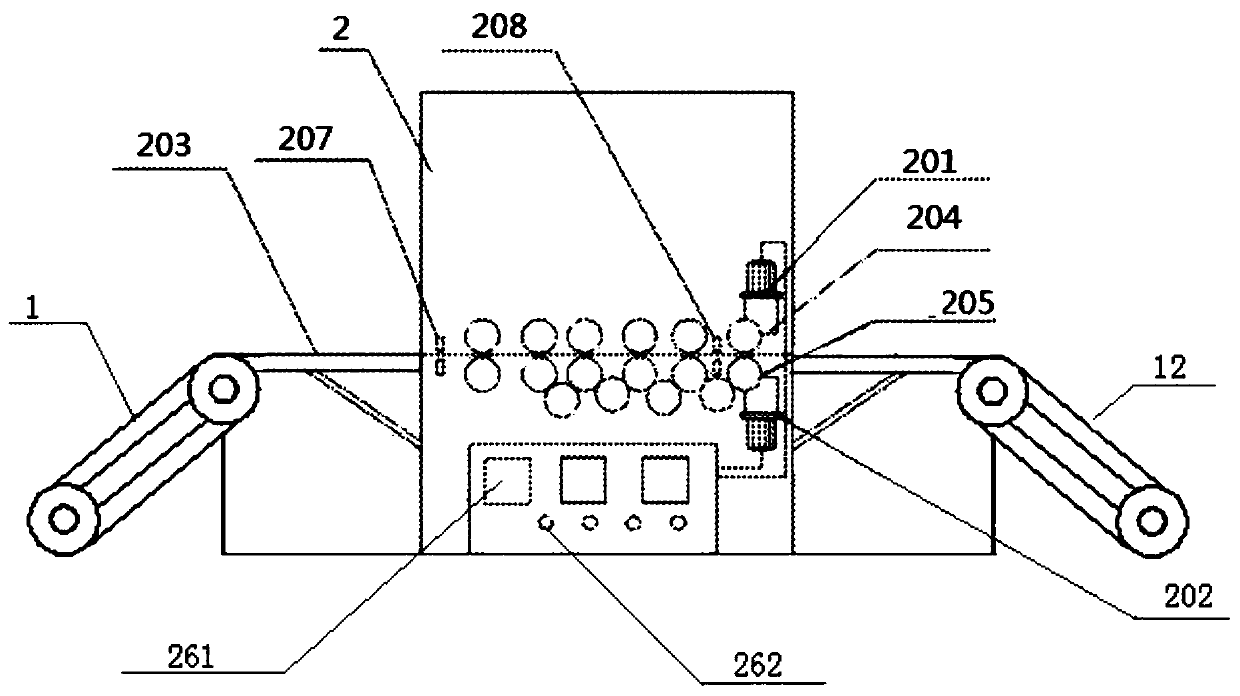

[0030] Please see figure 2 , is a structural schematic diagram of a preferred embodiment of an intelligent leveling machine according to the present invention. An intelligent leveling machine includes a feed conveyor belt 1, a frame 2, an inlet pallet 203, an upper leveling roller 204, a lower leveling roller 205, Upper leveling roller motor 201, lower leveling roller motor 202, control box 206, outlet pallet 209, discharge conveyor belt 12, the feed conveyor belt 1 is connected with the inlet pallet 203, and the discharge conveyor belt 12 is connected with the outlet pallet 209 are connected, the inlet pallet 203 and the outlet pallet 209 are installed on the left and right sides of the frame 2 respectively, and the upper calibration roller motor 201 and the lower calibration roller motor 202 are respectively connected to the upper calibration roller 204 and the lower calibration roller 205, so The feeding end between the above-mentioned upper leveling roller motor 201 and t...

Embodiment 2

[0043] Please see figure 2 , is a structural schematic diagram of a preferred embodiment of an intelligent leveling machine according to the present invention. An intelligent leveling machine includes a feed conveyor belt 1, a frame 2, an inlet pallet 203, an upper leveling roller 204, a lower leveling roller 205, Upper leveling roller motor 201, lower leveling roller motor 202, control box 206, outlet pallet 209, discharge conveyor belt 12, the feed conveyor belt 1 is connected with the inlet pallet 203, and the discharge conveyor belt 12 is connected with the outlet pallet 209 are connected, the inlet pallet 203 and the outlet pallet 209 are installed on the left and right sides of the frame 2 respectively, and the upper calibration roller motor 201 and the lower calibration roller motor 202 are respectively connected to the upper calibration roller 204 and the lower calibration roller 205, so The feeding end between the above-mentioned upper leveling roller motor 201 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com