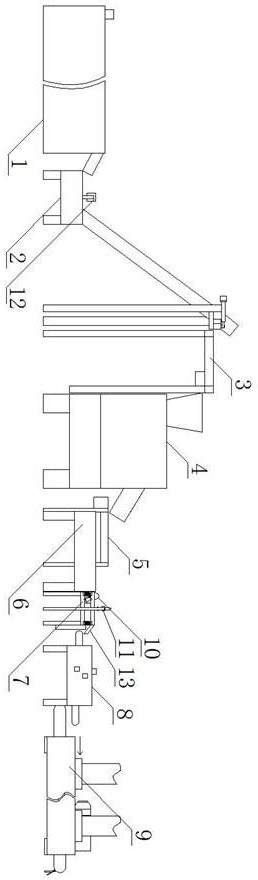

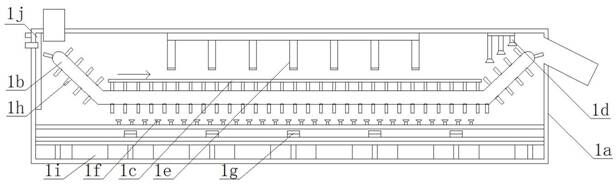

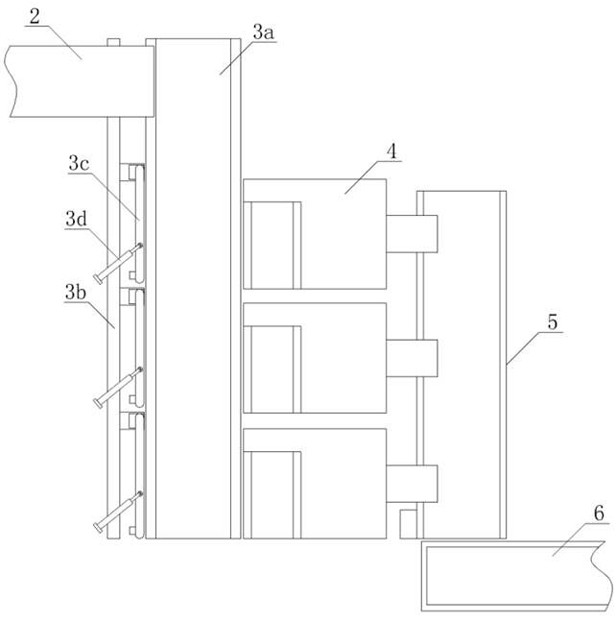

A kind of automatic frying and baking production system and production method of fruit ingredients

A technology for production systems and ingredients, applied in food science, food processing, applications, etc., can solve the problems of low degree of automation, low processing efficiency, blackening, etc., to achieve a high degree of automation, prevent blackening of ingredients, and improve cleaning effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The production method of the automatic frying and roasting production system for fruit ingredients is to clean the fruits first, then cut them into long slices, round slices or cubes, spray salt water on both sides of the ingredients, and then brand the ingredients on one or both sides. Then apply cooking oil to both sides of the ingredients, and fry the ingredients at a temperature of 100°C for 10 minutes.

Embodiment 2

[0054] The production method of the automatic frying and roasting production system for fruit ingredients is to clean the fruits first, then cut them into long slices, round slices or cubes, spray salt water on both sides of the ingredients, and then brand the ingredients on one or both sides. Then apply cooking oil to both sides of the ingredients, and fry the ingredients at a temperature of 200°C for 40 minutes.

Embodiment 3

[0056] The production method of the automatic frying and roasting production system for fruit ingredients is to clean the fruits first, then cut them into long slices, round slices or cubes, spray salt water on both sides of the ingredients, and then brand the ingredients on one or both sides. Then apply cooking oil to both sides of the ingredients, and fry the ingredients at a temperature of 150°C for 25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com