Preparation process of steamed stuffed bun skin

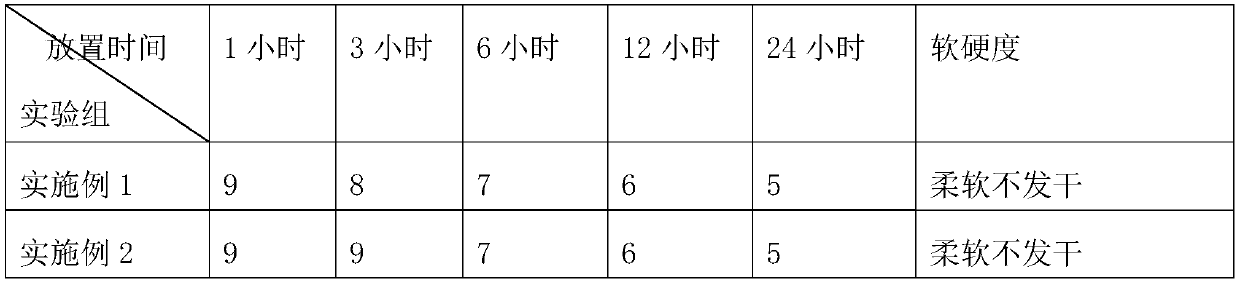

A preparation process, technology of steamed bun skin, applied in the field of steamed bun skin preparation technology, can solve problems such as steamed stuffed bun skin tends to dry out, reduce customer flow, affect sales volume, etc., shorten fermentation time, prevent dryness, and not easily dry out Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

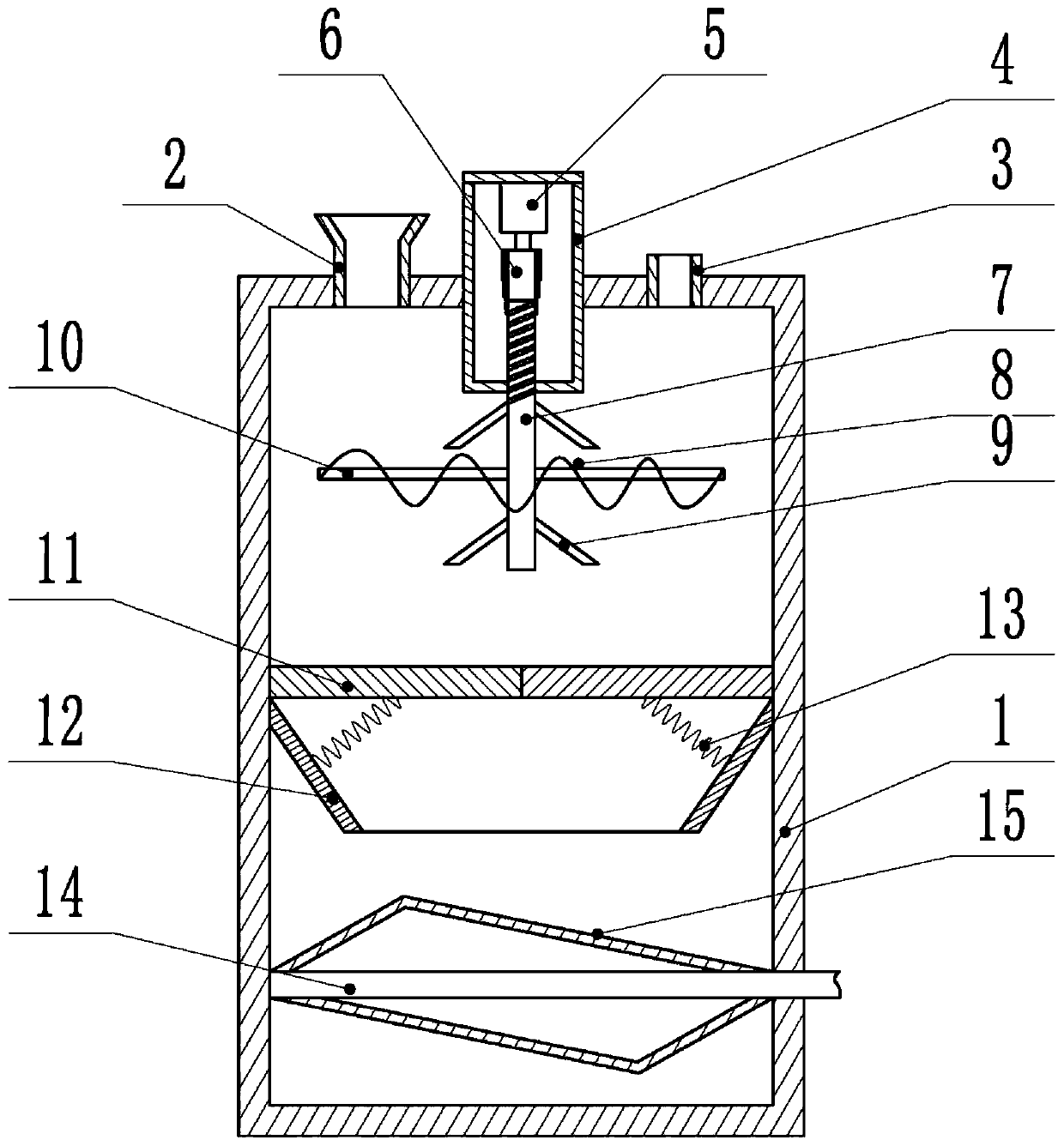

Method used

Image

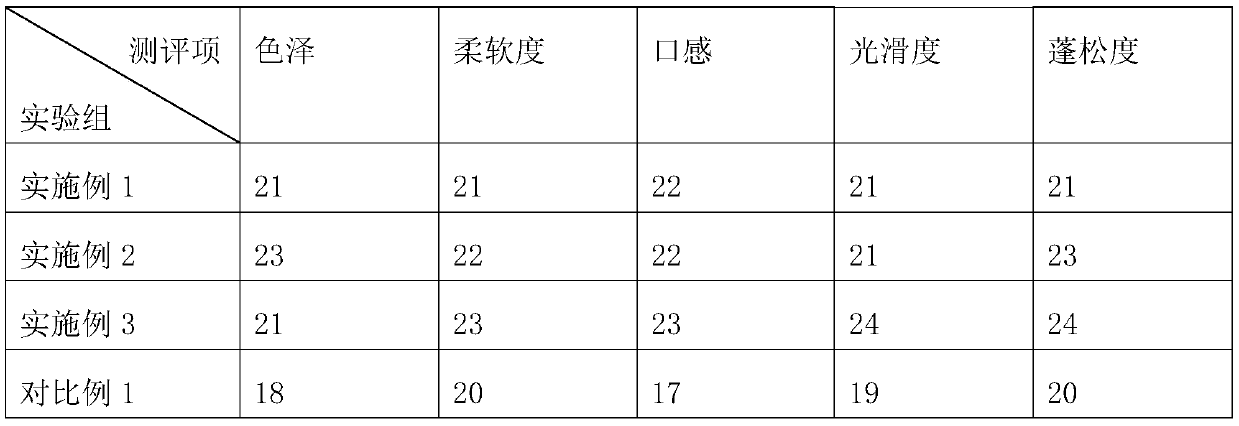

Examples

Embodiment 1

[0030] A preparation process for steamed bun skin, comprising the steps of:

[0031] (1) Prepare the following raw materials in parts by weight: 15 parts of flour, 0.3 part of yeast, 0.5 part of white sugar, 2 parts of eggs, 2 parts of salt, and 7 parts of water;

[0032] (2) Boil water: heat the water to 30-35°C for use;

[0033] (3) Melt the yeast: Pour the flour into the kneading device, put the yeast into the bowl, and add white sugar to the yeast, then pour 0.5 part of the water in step (2) into the bowl to make the yeast and white sugar The granulated sugar is melted, and the fermented liquid is prepared for later use;

[0034] (4) leavening: pour the fermented liquid in the step (3) into the flour, and simultaneously stir the fermented liquid and the flour evenly to obtain a semi-finished product;

[0035] (5) Kneading the dough: break the eggs and separate the egg white and egg yolk, and add the separated egg white to the semi-finished product prepared in step (4), a...

Embodiment 2

[0049] A preparation process for steamed bun skin, comprising the steps of:

[0050] (1) Prepare the following raw materials in parts by weight: 30 parts of flour, 0.6 parts of yeast, 1 part of white sugar, 3 parts of eggs, 3 parts of salt, 15 parts of water, 1 part of baking powder, and 2 parts of oil;

[0051] (2) Boil water: heat the water to 30-35°C for use;

[0052] (3) Melt the yeast: Pour the flour into the kneading device, put the yeast into the bowl, and add white sugar to the yeast, then pour 0.5 part of the water in step (2) into the bowl to make the yeast and white sugar The granulated sugar is melted, and the fermented liquid is prepared for later use;

[0053] (4) leavening: pour the fermented liquid in the step (3) into the flour, and simultaneously stir the fermented liquid and the flour evenly to obtain a semi-finished product;

[0054] (5) Kneading the dough: break the eggs and separate the egg white and egg yolk, and add the separated egg white to the semi...

Embodiment 3

[0059] A preparation process for steamed bun skin, comprising the steps of:

[0060] (1) Prepare the following raw materials in parts by weight: 20 parts of flour, 0.5 parts of yeast, 0.8 parts of white sugar, 2 parts of eggs, 2 parts of salt, 10 parts of water, 0.8 parts of baking powder, and 1 part of oil;

[0061] (2) Boil water: heat the water to 30-35°C for use;

[0062] (3) Melting the yeast: Pour the flour into the kneading device, put the yeast into a bowl, and add white sugar to the yeast, then pour 1 part of the water in step (2) into the bowl to make the yeast and white sugar The granulated sugar is melted, and the fermented liquid is prepared for later use;

[0063] (4) leavening: pour the fermented liquid in the step (3) into the flour, and simultaneously stir the fermented liquid and the flour evenly to obtain a semi-finished product;

[0064] (5) Kneading the dough: break the eggs and separate the egg white and egg yolk, and add the separated egg white to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com