Gradient dot matrix structure design method based on topological optimization

A technology of lattice structure and topology optimization, applied in computing, special data processing applications, instruments, etc., to achieve the effect of ensuring rationality, high algorithm efficiency, and avoiding repetition

- Summary

- Abstract

- Description

- Claims

- Application Information

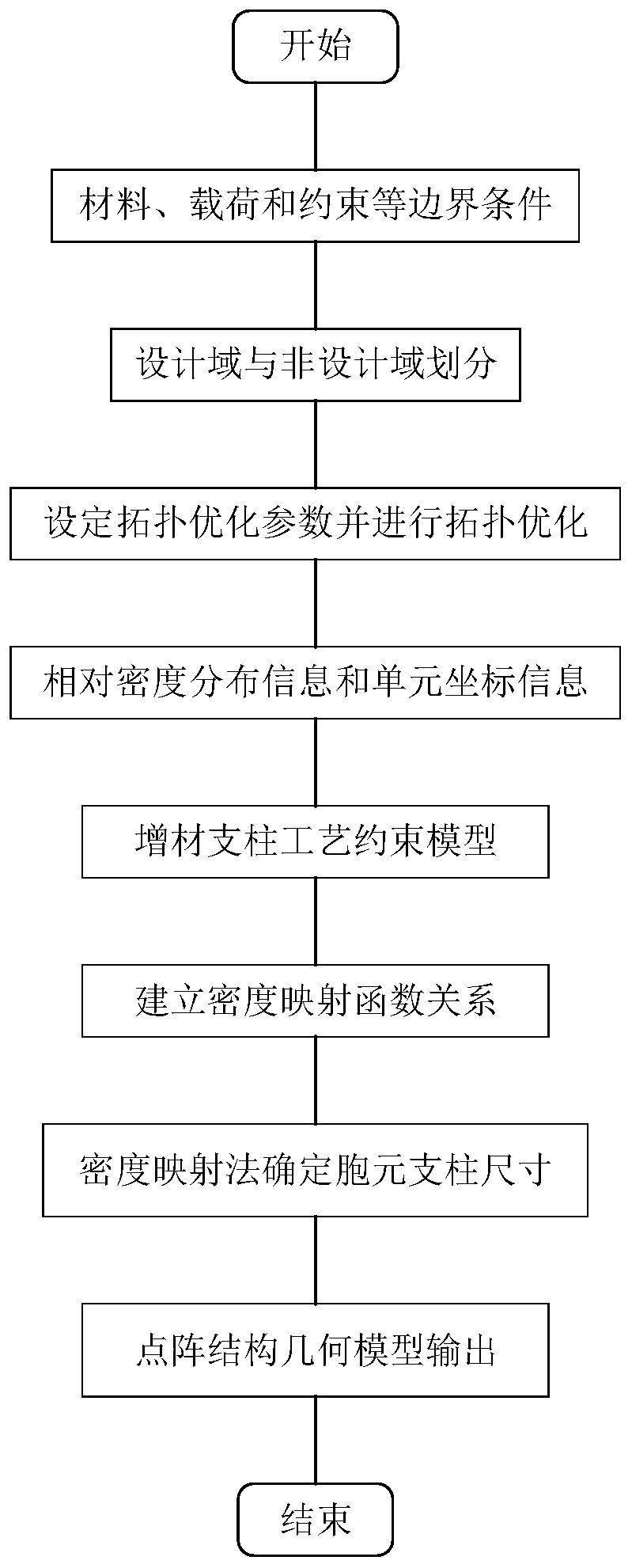

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

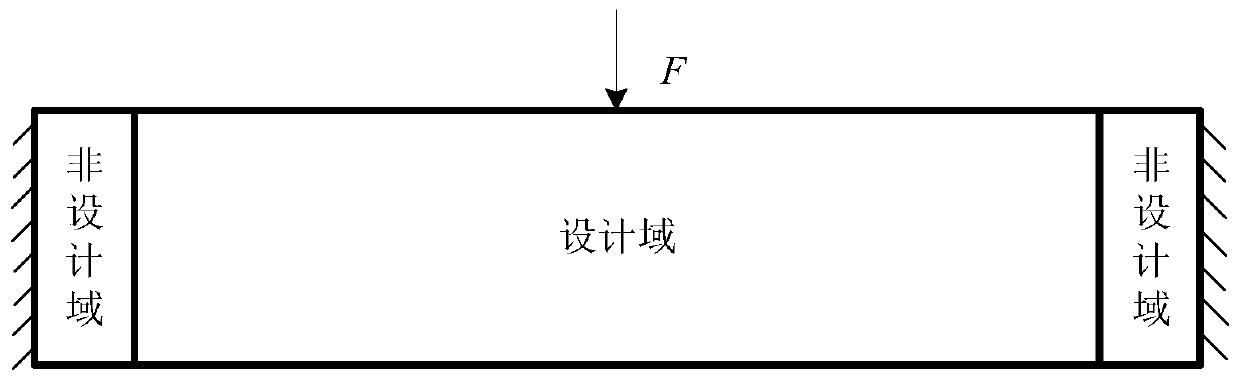

[0042] S1: Take the supporting device of a quadrotor aircraft wing as an example below to illustrate the present invention. Such as figure 2 As shown, the circular hole at the left end of the structure bears the tensile force along the axis, the circular hole at the right end bears the fixed constraint, and the middle connecting rod plays the role of connecting structure and transmitting force. Establish the finite element model of the initial structure, the structural material is stainless steel, its elastic modulus E = 2e11Pa, Poisson's ratio υ = 0.3, density ρ = 7.9e-3g / mm 3 . The design domain and non-design domain of the structure are divided as figure 2 shown.

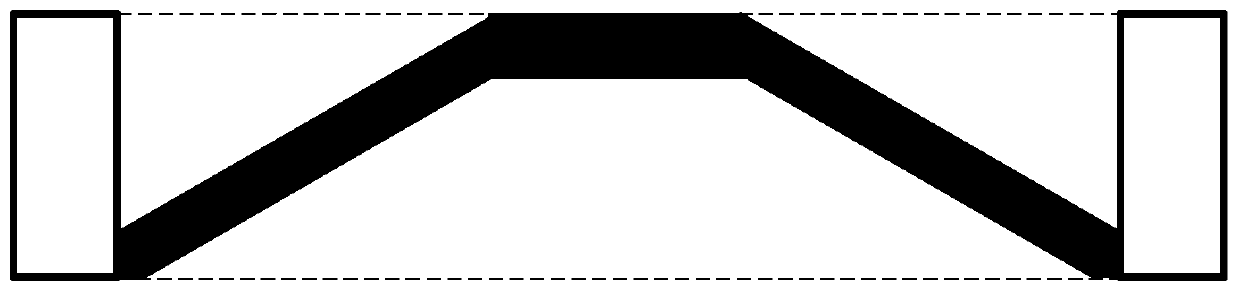

[0043] S2: Set the penalty factor of topology optimization to 3, the volume fraction to 0.4, and use the variable density method for topology optimization design. The obtained topology optimization results are as follows image 3 As shown, the display threshold of unit density in this result is 0.3, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com