A disc-type strain multiplier for amplifying surface strain of a mechanical part in real time under multi-axis load and a design method

A technology of mechanical parts and multi-axis loading, applied in instruments, calculations, special data processing applications, etc., can solve the problem of low magnification of strain multipliers, and achieve the effect of improving service life, reducing concentrated stress and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

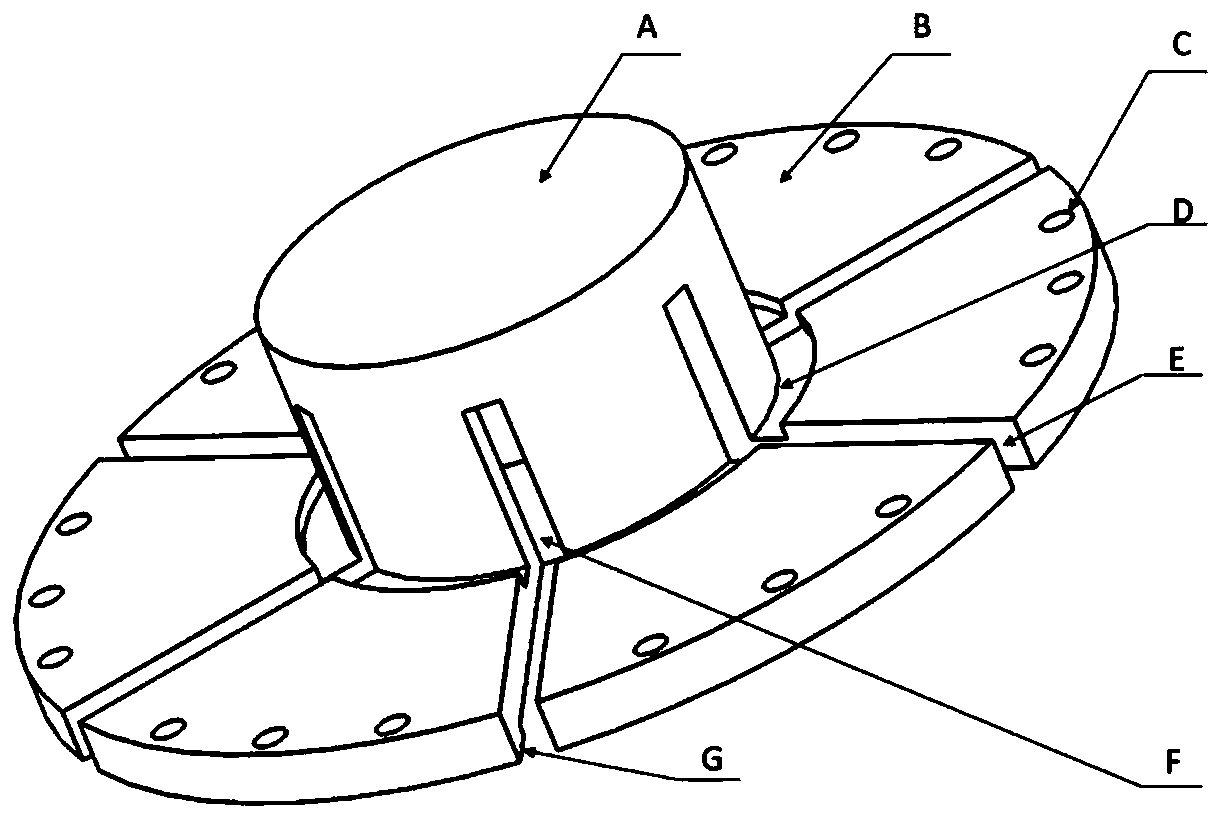

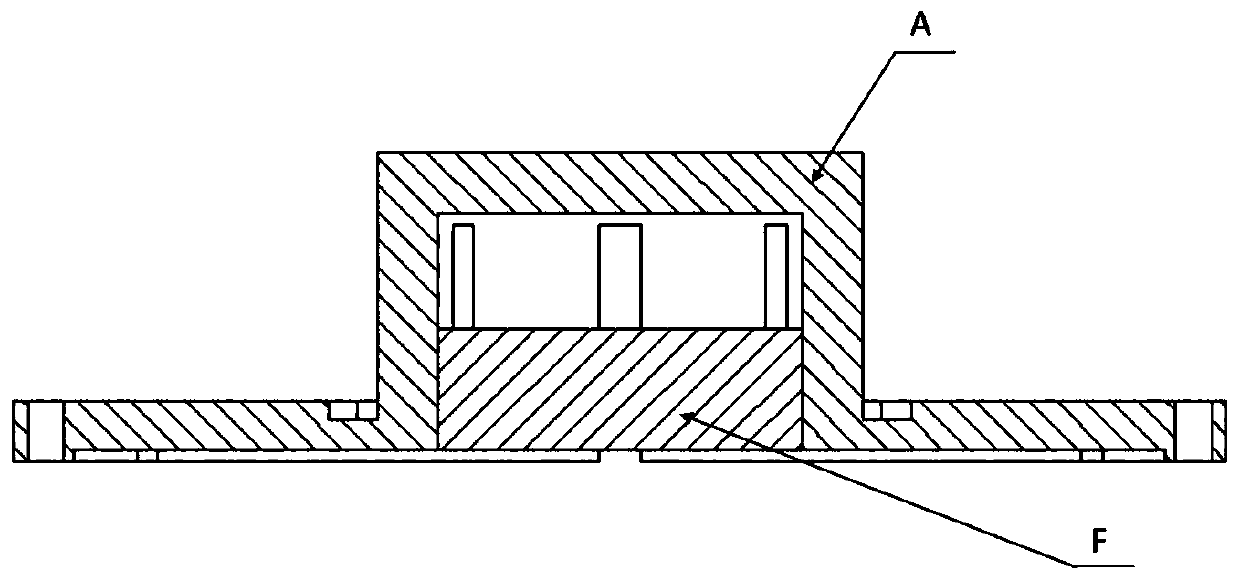

[0033] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

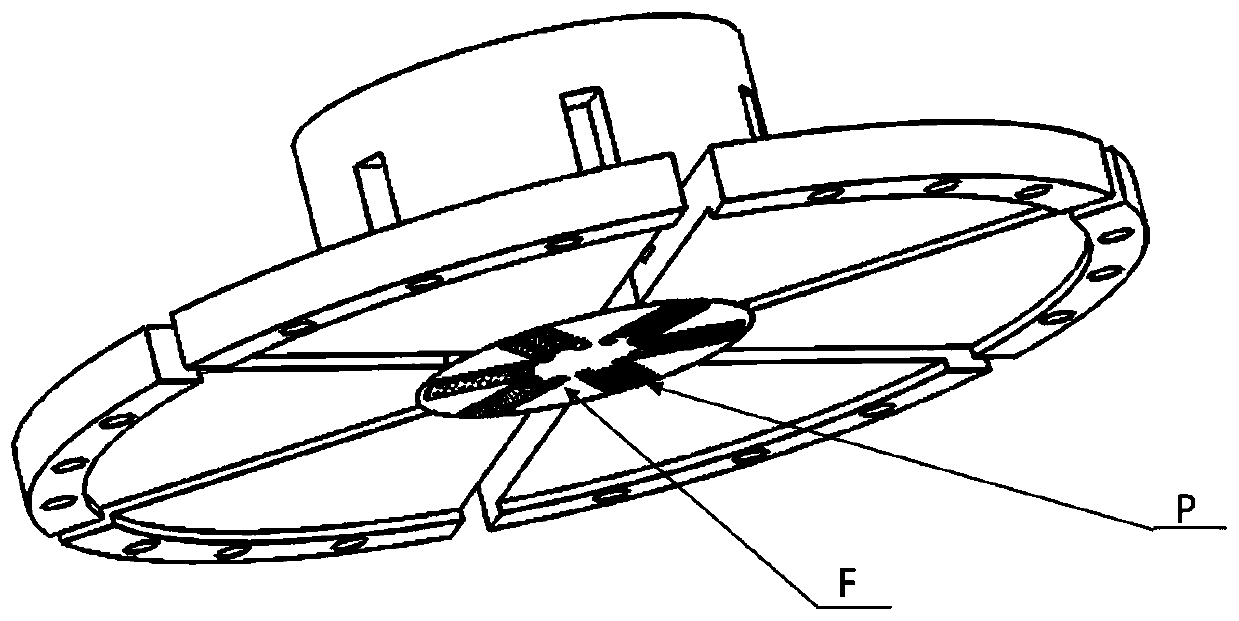

[0034] Figure 5 It is a schematic diagram of the specific installation of the disc strain multiplier. The disc strain multiplier S uses the strain transfer method to amplify the strain on the surface of the tested mechanical part H in all directions in the same proportion. The disk surface of the device S receives the surface stress of the mechanical structure, and transmits the stress to the rubber body F of the disk center to transfer the strain, and realizes the real-time amplification of the strain by using the superelasticity of the rubber body F of the disk center.

[0035] 1) When the disc center rubber body F is glued to the inner hole of the central hollow cylinder A, an interference fit is used to ensure that the disc strain multiplier S can still rely on its own deformation and inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com