Nondestructive testing method for residual stress in thermal barrier coating

A thermal barrier coating, residual stress technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc. The problem of measuring the accurate stress value of thermal barrier coatings, etc., achieves the effect of real-time monitoring of service conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

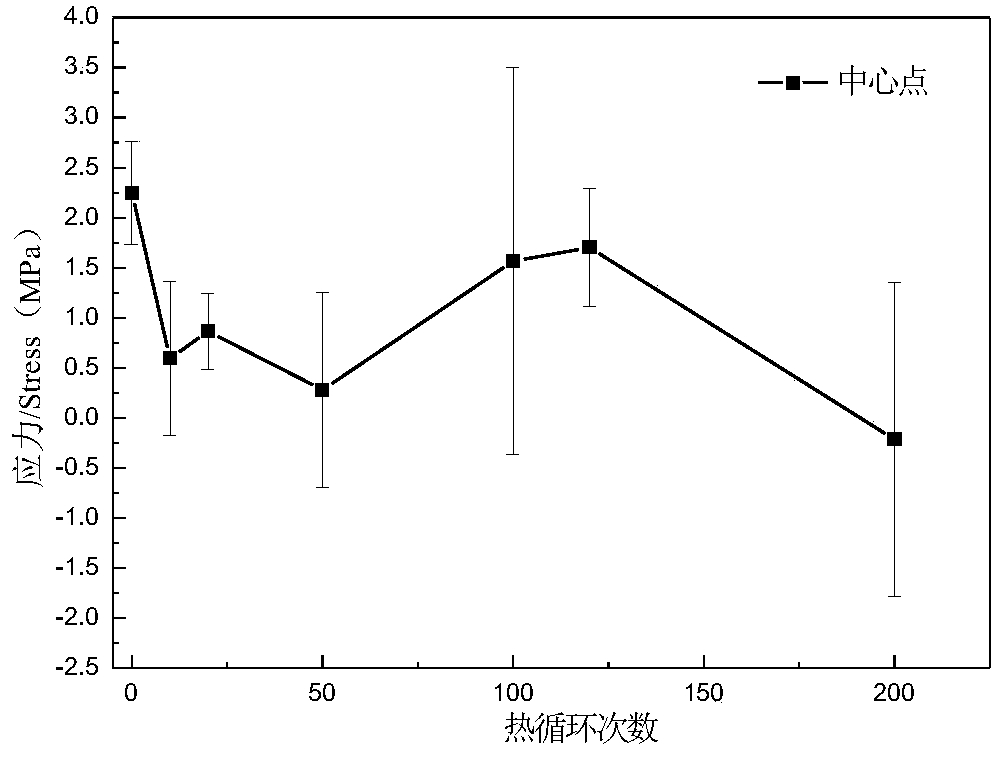

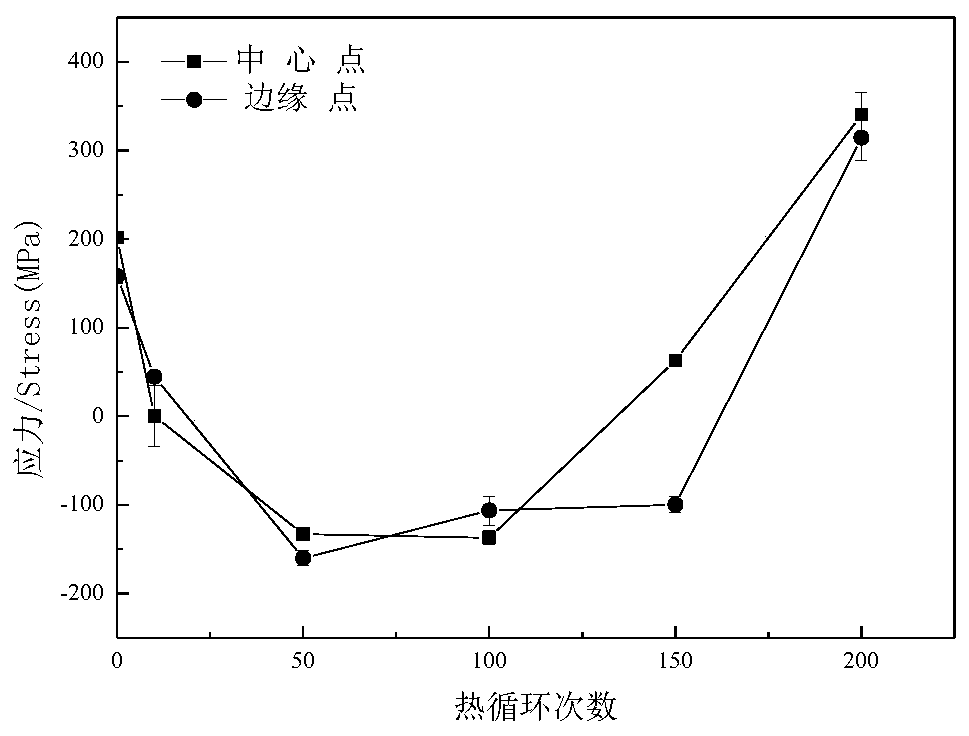

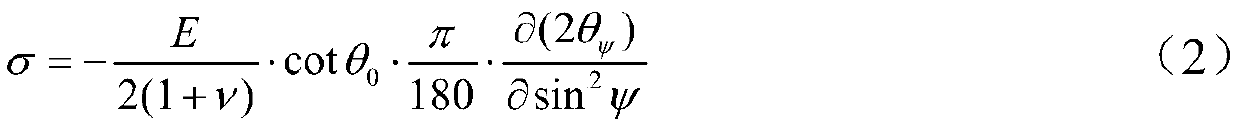

[0022] Place the thermal barrier coating sample horizontally on the sample stage of the Empyrean X-ray diffraction instrument and fix it, so that the normal direction of the sample is consistent with the normal direction of the incident ray, then set the scanning range and measurement method, and measure respectively. X-ray diffraction patterns at different tilt angles. The power of the ceramic X-ray tube is adjusted to 4KW, and the specific frequency of X-ray emission is 1.95×10 18 HZ, the reproducibility of the goniometer is 0.00003 degrees, the controllable minimum step is 0.00003 degrees, the maximum count rate of the PIXcel3D super detector is 120cps, and it is determined according to the relationship between the displacement of the X-ray diffraction peak and the macroscopic stress. Residual stress at a depth of 10 μm in thermal barrier coatings.

Embodiment 2

[0024] Place the thermal barrier coating sample horizontally on the sample stage of the Empyrean X-ray diffraction instrument and fix it, so that the normal direction of the sample is consistent with the normal direction of the incident ray, then set the scanning range and measurement method, and measure respectively. X-ray diffraction patterns at different tilt angles. Adjust the power of the ceramic X-ray tube to 5KW and the specific frequency of X-ray emission to 3×10 18 HZ, the reproducibility of the goniometer is 0.00005 degrees, the minimum controllable step is 0.00007 degrees, and the maximum count rate of the PIXcel3D super detector is 160 cps, which is determined according to the relationship between the displacement of the X-ray diffraction peak and the macroscopic stress. Residual stress in the thermal barrier coating at a maximum depth of 23 μm.

Embodiment 3

[0026] Place the thermal barrier coating sample horizontally on the sample stage of the Empyrean X-ray diffraction instrument and fix it, so that the normal direction of the sample is consistent with the normal direction of the incident ray, then set the scanning range and measurement method, and measure respectively. X-ray diffraction patterns at different tilt angles. Adjust the power of the ceramic X-ray tube to 6KW and the specific frequency of X-ray emission to 9×10 18 HZ, the reproducibility of the goniometer is 0.00006 degrees, the minimum controllable step is 0.00005 degrees, and the maximum count rate of the PIXcel3D super detector is 160 cps, which is determined according to the relationship between the displacement of the X-ray diffraction peak and the macroscopic stress. Residual stress at a depth of 67 μm in thermal barrier coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com