Net preparation system

A preparation system and mesh technology, applied in the field of mesh preparation systems, can solve the problems of affecting air permeability, blockage, high cost, etc., and achieve the effects of multi-permeability, convenient installation and use, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

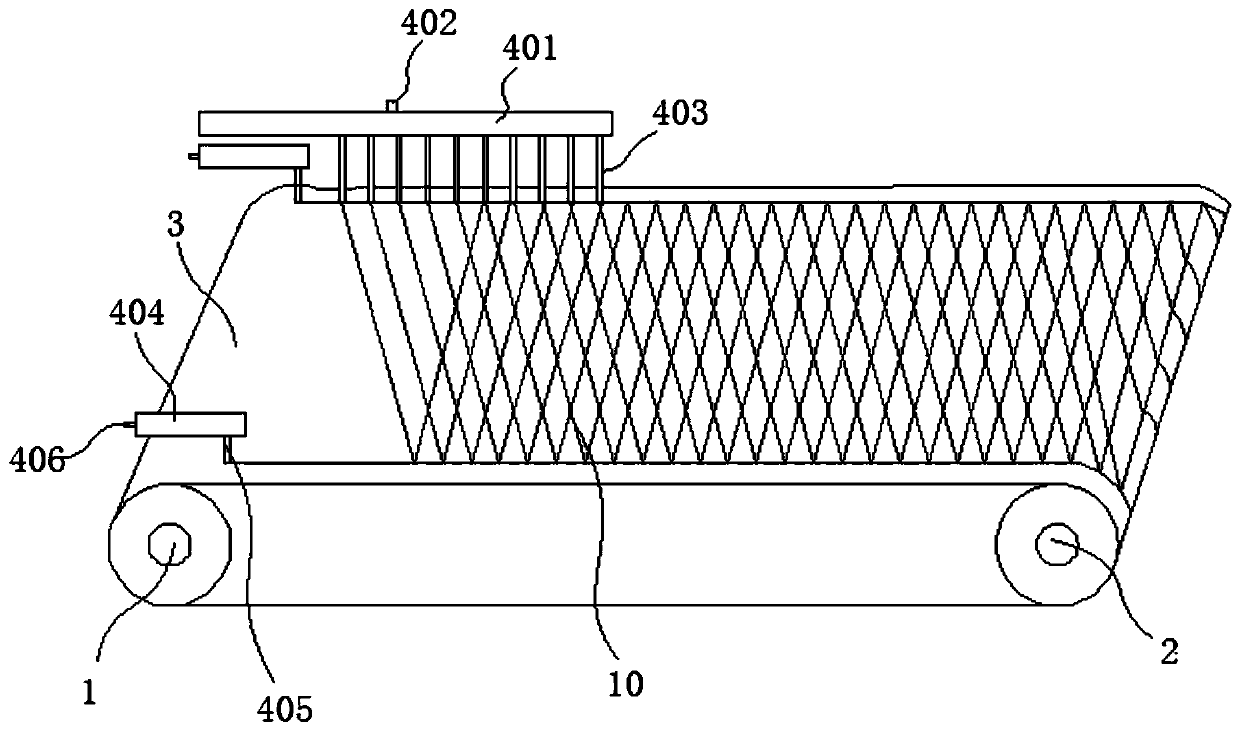

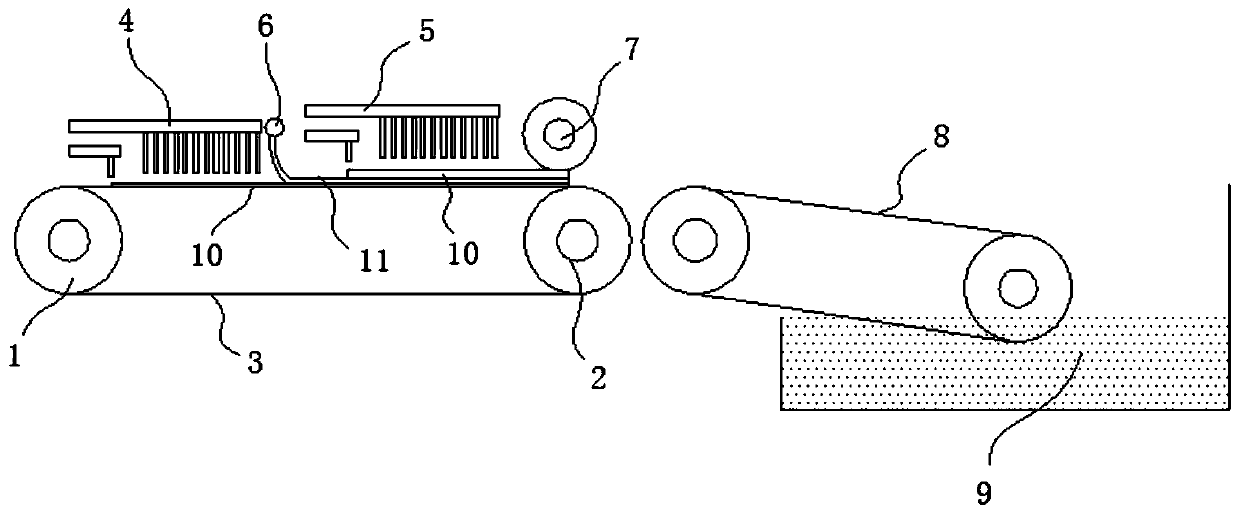

[0031] See figure 1 , figure 2 , Is a mesh preparation system provided by an embodiment of the present invention, such as figure 1 , figure 2 As shown, the system includes a first roller 1 and a second roller 2. The first roller 1 and the second roller 2 are parallel and their respective axes are arranged horizontally; the first roller 1 and the second roller 2 There is a crawler belt 3 between them; the crawler belt 3 can run around the first roller 1 and the second roller 2;

[0032] The first unloading assembly 4, the first unloading assembly includes a first squeezing arm 401, the longitudinal direction of the first squeezing arm 401 is perpendicular to the axial direction of the first drum 1 and is suspended on the crawler 3 Above; the first squeezing arm 401 has a cavity structure; the first squeezing arm 401 is provided with a first feeding port 402 connected to a fluid web material feeding mechanism, the first A plurality of first discharging pipes 403 are provided un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com