Suction labeling type automatic labeling structure, labeling method and set-top box labeling mechanism

A set-top box, automatic technology, applied in labeling machines, labels, packaging and other directions, can solve the problems of high cost, low labeling efficiency and accuracy, and achieve the effects of high labeling accuracy, improved work efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

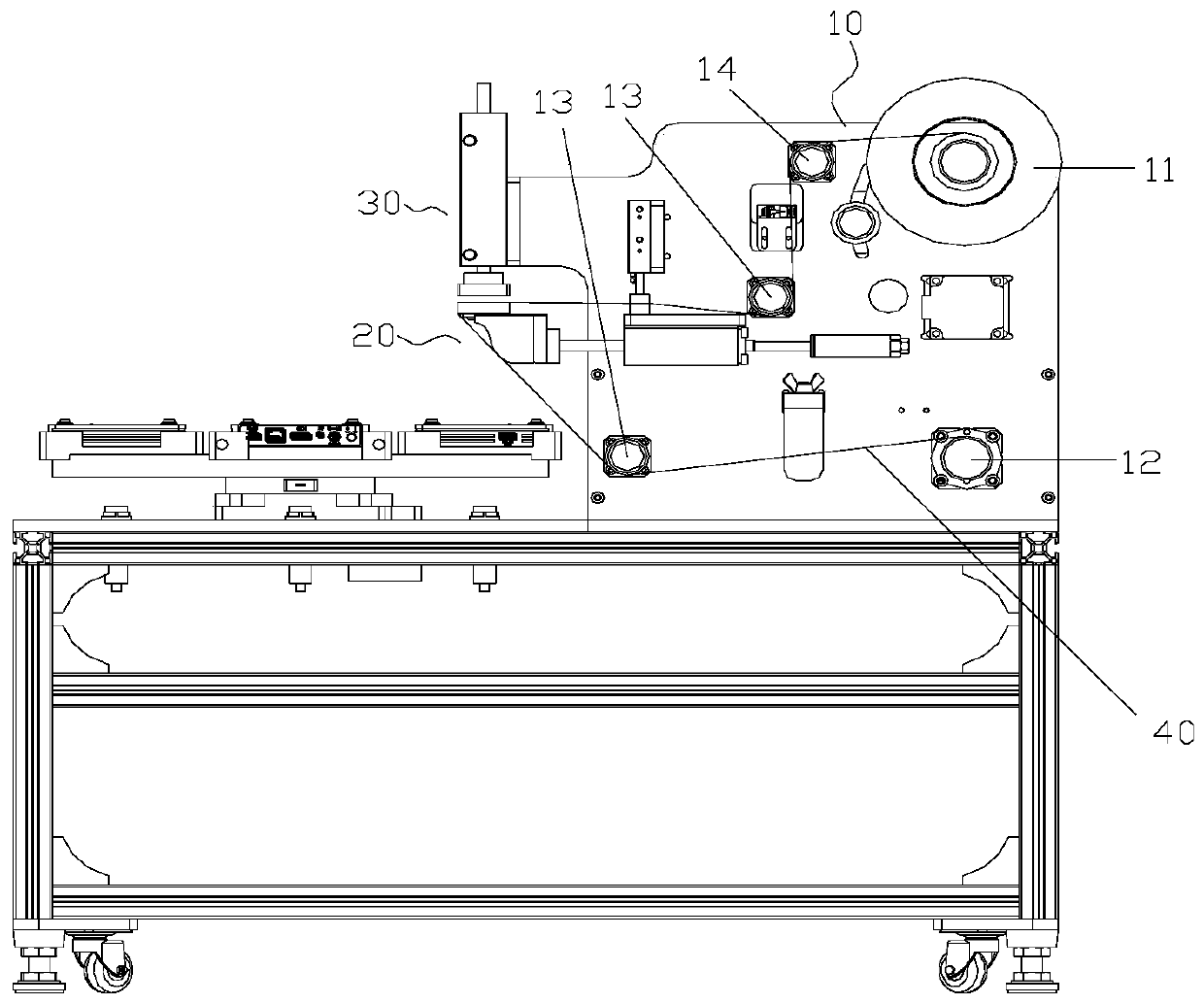

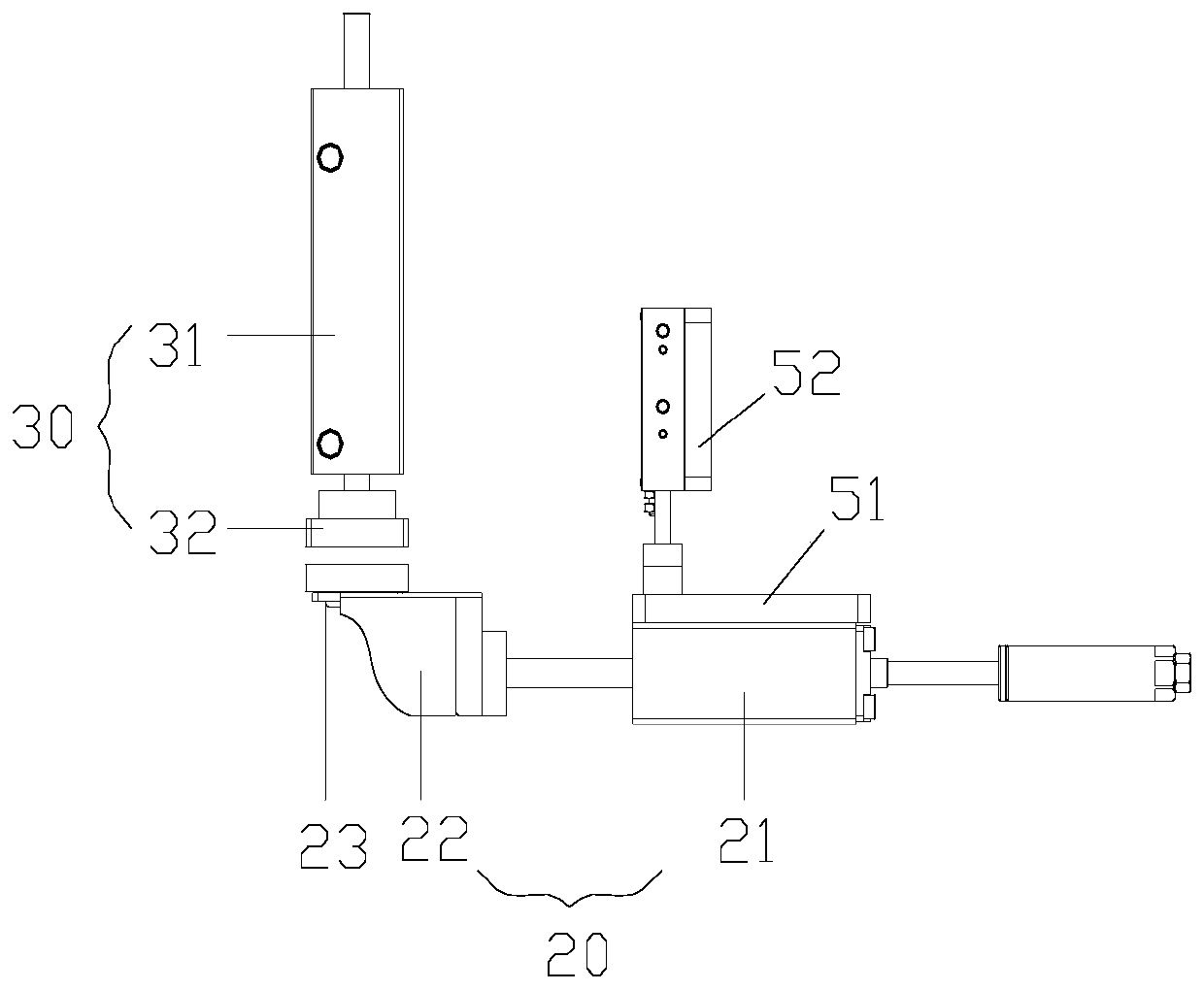

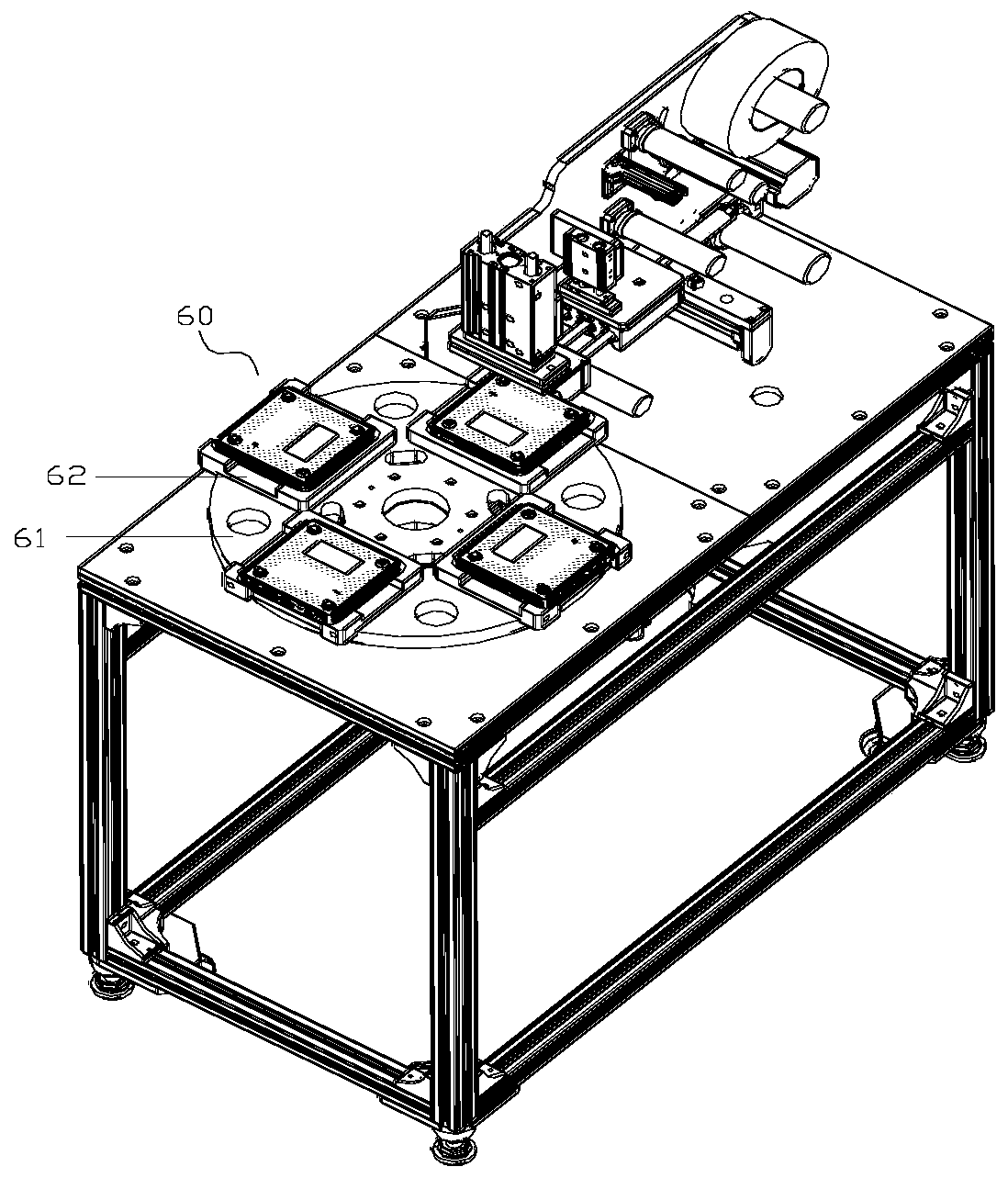

[0028] See figure 1 , in order to solve the above-mentioned technical problems, this embodiment provides a suction-stick type automatic labeling structure for peeling and labeling the label rolls wound into rolls, specifically including a label conveying mechanism 10, a label-peeling mechanism 20 and a labeling mechanism. Standard agency30.

[0029] The label conveying mechanism 10 includes a label roller 11 , a label receiving roller 12 , a traction roller set 13 and a guide roller set 14 . The label roll is installed on the label roller 11, and the drawn label tape 40 is wound on the traction roller group 13 and the guide roller group 14 in turn, and wound on the stripping mechanism 20 to complete the stripping, and the stripped label tape 40 is wound on the On the receiving roller 12. The traction roller group 13 of the label conveying mechanism 10 provides the driving force for the transportation of the label tape 40, and is driven by the motor to rotate by the extrusion...

Embodiment 2

[0037] This embodiment provides a suction-stick type automatic labeling structure for peeling and labeling the wound label roll, which also includes a label conveying mechanism 10 , a label-peeling mechanism 20 and a labeling mechanism 30 .

[0038] As a further improvement of the technical solution, this embodiment differs from the embodiment 1 in that it further includes a processing unit, and a tension detection device is provided on the moving path of the label tape 40 . The pulling roller set 13 is located at least before and after the peeling corner 23 of the peeling block 22 respectively, and the tension detection device and the pulling roller set 13 are respectively electrically connected to the processing unit.

[0039] The tension detection device realizes the detection of the tension of the label tape 40, and the detected tension data is transmitted to the processing unit, and the processing unit processes the tension data to obtain the control signal of the traction r...

Embodiment 3

[0042] This embodiment provides a suction-stick type automatic labeling structure for peeling and labeling the wound label roll, which also includes a label conveying mechanism 10 , a label-peeling mechanism 20 and a labeling mechanism 30 .

[0043] In Embodiment 1, after the label absorbing plate 32 absorbs the label, the first cylinder 21 retracts, and the label is under the joint action of the stripping angle 23 and the label absorbing plate 32, and the first cylinder 21 drives the stripping block 22 to retract. During the process, the label tape 40 at the peeling corner 23 will be in a slack state, and in the relaxed state of the label tape 40, the peeling corner 23 cannot peel off the label.

[0044] For this reason, as a further improvement of the technical solution, the difference between this embodiment and Embodiment 1 is that the present embodiment is provided with a spacer 51 flush with the first end face below the label tape 40 in front of the stripping block 22. 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com