Concrete mixing machine and cleaning system used for cleaning concrete mixing machine

A technology for a concrete mixer and a cleaning system, which is applied to cement mixing devices, dryers, cleaning hollow objects, etc., can solve the problems of reducing the service life of the mixing drum, unable to clean the concrete, destroying the structure of the mixing drum, etc., to reduce corrosion. Probability, reduce the possibility of remaining in the mixing drum, the effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

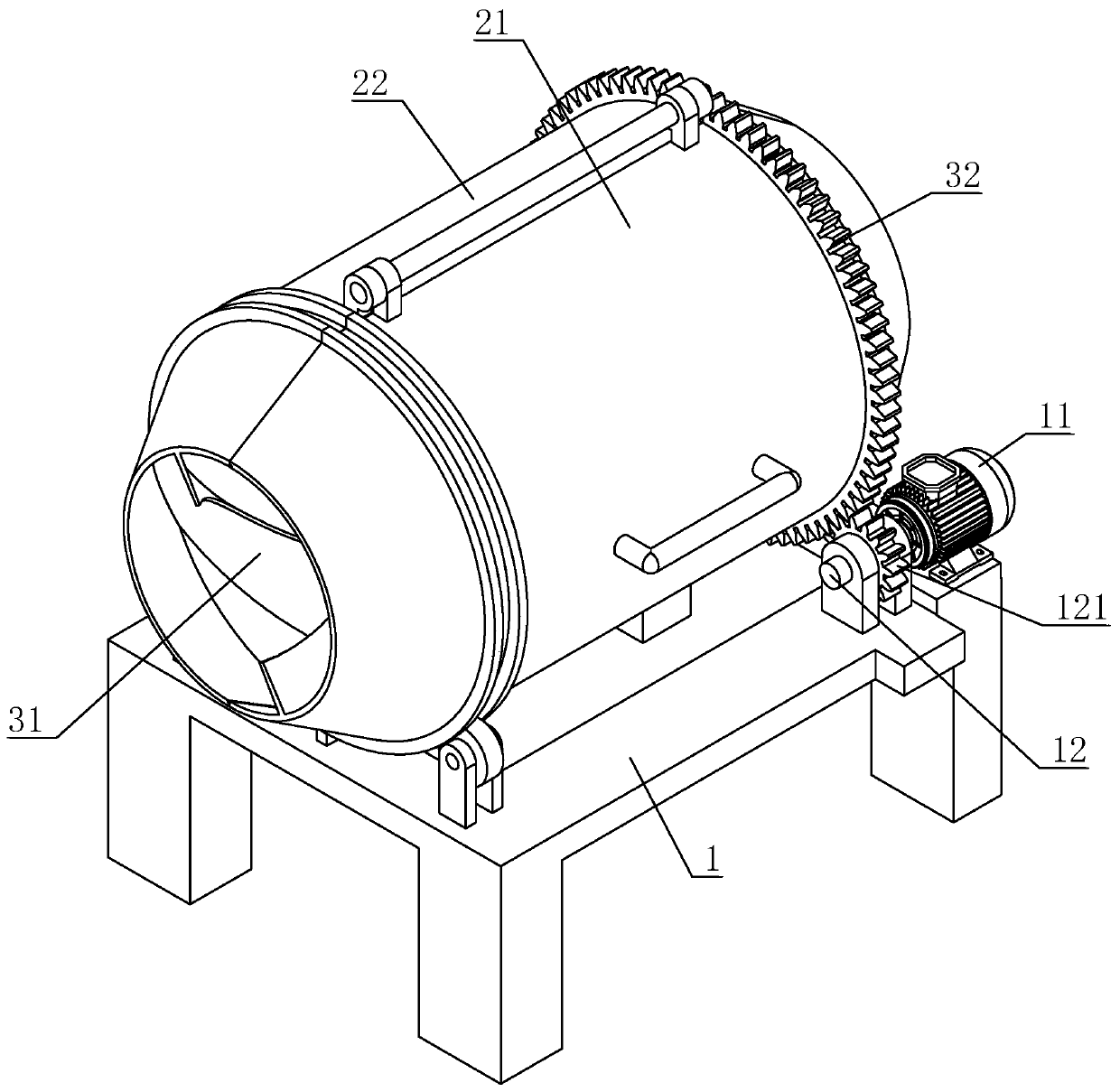

[0048] A concrete mixer, refer to figure 1 , including a frame 1, a power assembly is arranged on the frame 1, and the power assembly includes a third motor 11, and two linkage rods 12 in parallel intervals are rotated on the frame 1, and the third motor 11 and one of the linkage rods 12 Fixed connection at one end.

[0049] refer to figure 2 , the two linkage rods 12 are rotated with a mixing drum, and the mixing drum is provided with a stirring blade 31; the linkage rod 12 is fixedly installed with a first gear 121, and the outside of the mixing drum is provided with a ring gear 32 meshing with the first gear 121; The three motors 11 drive the linkage rod 12 to rotate, the first gear 121 and the linkage rod 12 rotate synchronously, and the first gear 121 drives the ring gear 32 to move, thereby realizing the rotation of the mixing drum.

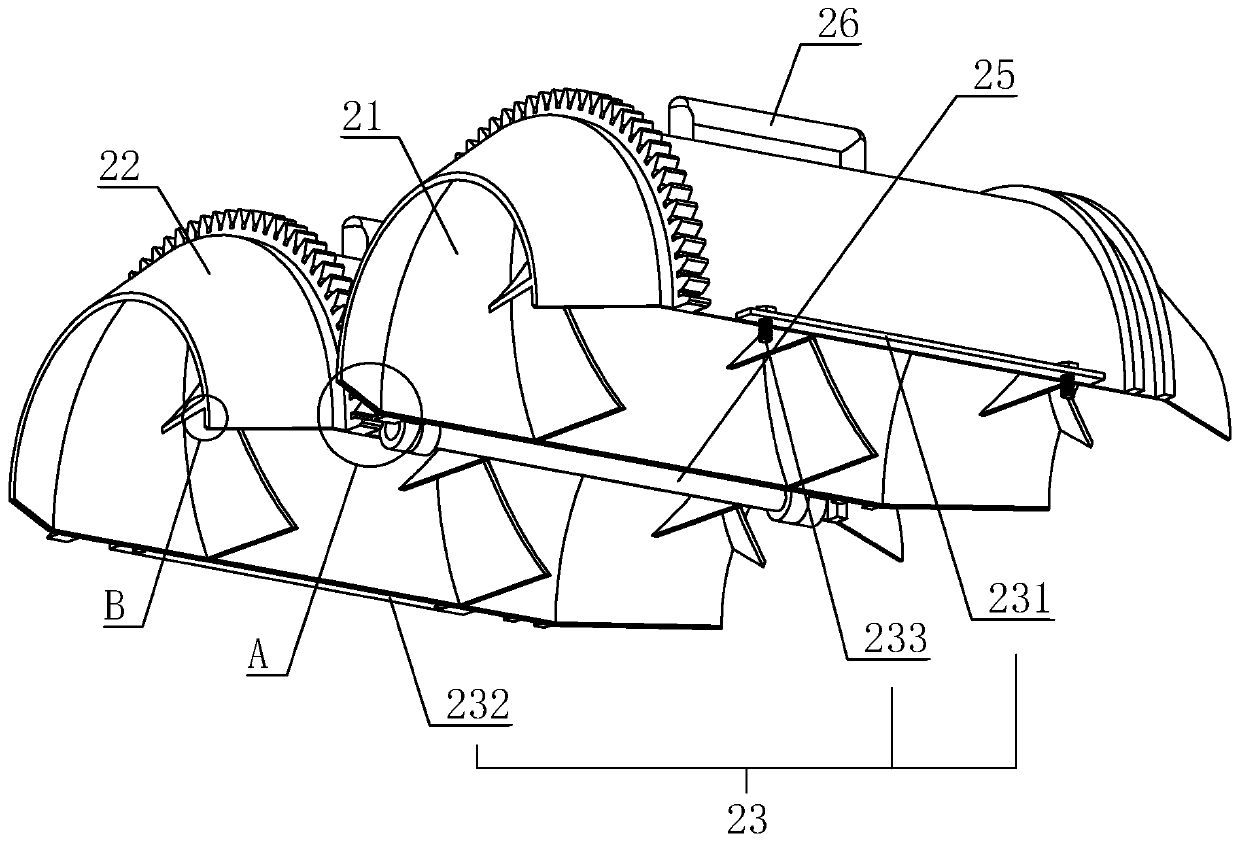

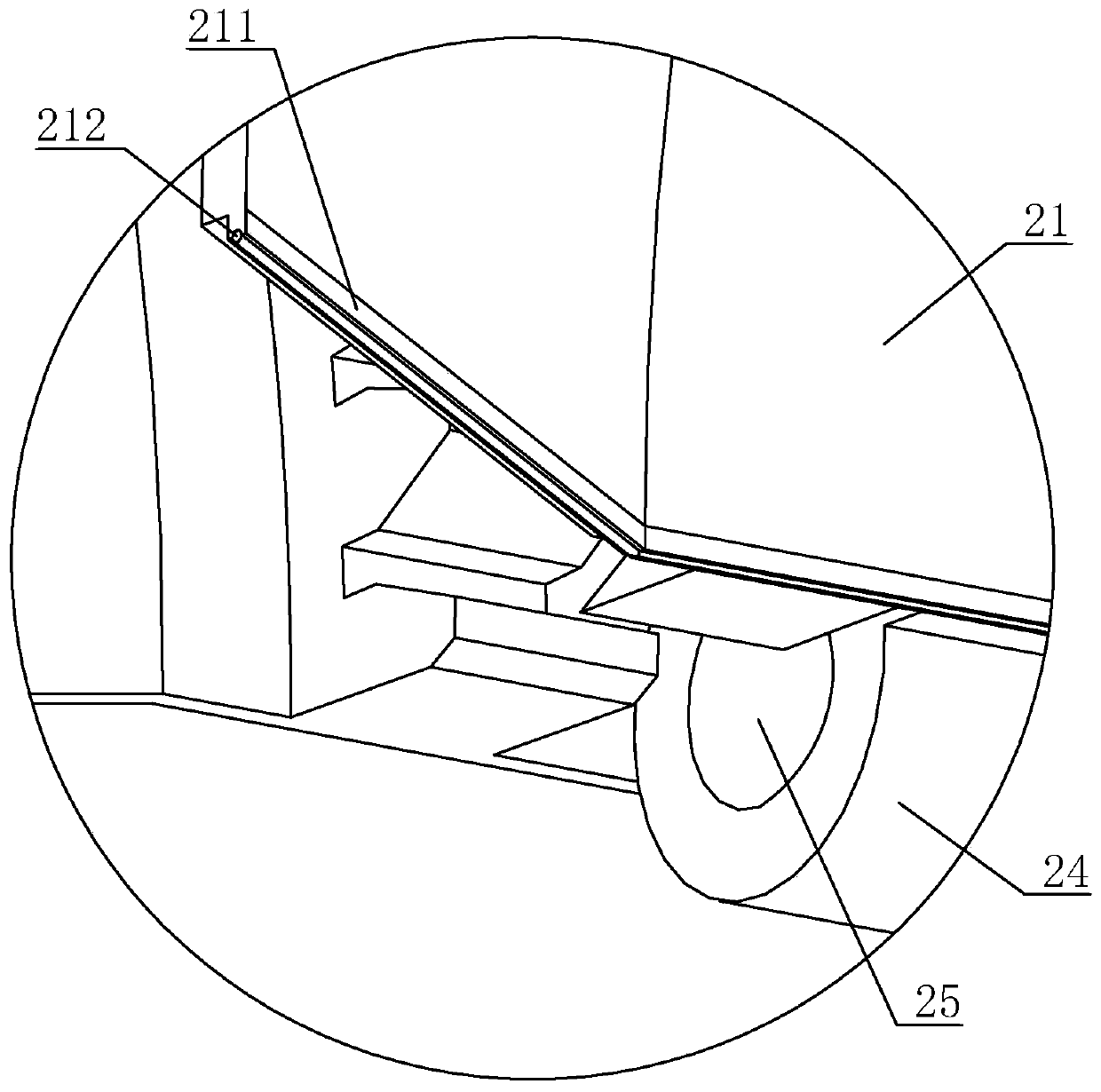

[0050] refer to figure 2 and image 3 , the mixing drum includes a first half cylinder 21 , a second half cylinder 22 and a connecti...

Embodiment 2

[0055] A kind of cleaning system, is used for cleaning the concrete mixer in embodiment one, with reference to Figure 5 , comprising a driving frame 4, two sliding rods 41 spaced in parallel are fixedly arranged on the top of the driving frame 4, a moving seat 42 is provided for sliding on the sliding rods 41, and a driving assembly 43 is arranged on the driving frame 4, The drive assembly 43 includes a fourth motor 431 and a third threaded rod 432, the fourth motor 431 is fixedly arranged on the vehicle frame 4, the third threaded rod 432 is rotatably installed on the vehicle frame 4, the third threaded rod 432 is connected with the mobile seat 42 threads are matched, the output shaft of the fourth motor 431 is fixedly connected with one end of the third threaded rod 432, the rotation of the fourth motor 431 drives the third threaded rod 432 to rotate, and the third threaded rod 432 can drive the moving seat 42 along the sliding rod 41 movement.

[0056] refer to Figure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com