Human-like dual-arm cooperative robot based on synchronous pulley transmission

A technology of synchronous pulleys and robots, which is applied in the field of robots, can solve the problems that cannot be applied to occasions with small working space, cannot meet the requirements of high-precision positioning, and the vibration at the end of the robot is large, etc., and achieves easy motor maintenance, small footprint, and cable bus easy effect

Inactive Publication Date: 2019-05-17

CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The traditional SCARA robot is driven by direct drive, which has the characteristics of low price, but the motor is located in each joint, and the cable routing makes the rotation angle of the joint limited; the vertical space of the end arm is large and cannot be used in the working space Smaller occasions; the direct drive transmission method makes the end of the robot vibrate greatly, which cannot meet the occasions with high-precision positioning requirements, such as wafer loading and unloading

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the forearm motor 7a, the middle arm motor 8a, and the end arm motor 9a all use servo motors, and the 3D camera 13 uses a line structured light camera.

Embodiment 3

[0050] The difference between this embodiment and the first embodiment is that the 3D camera 13 adopts a TOF camera.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

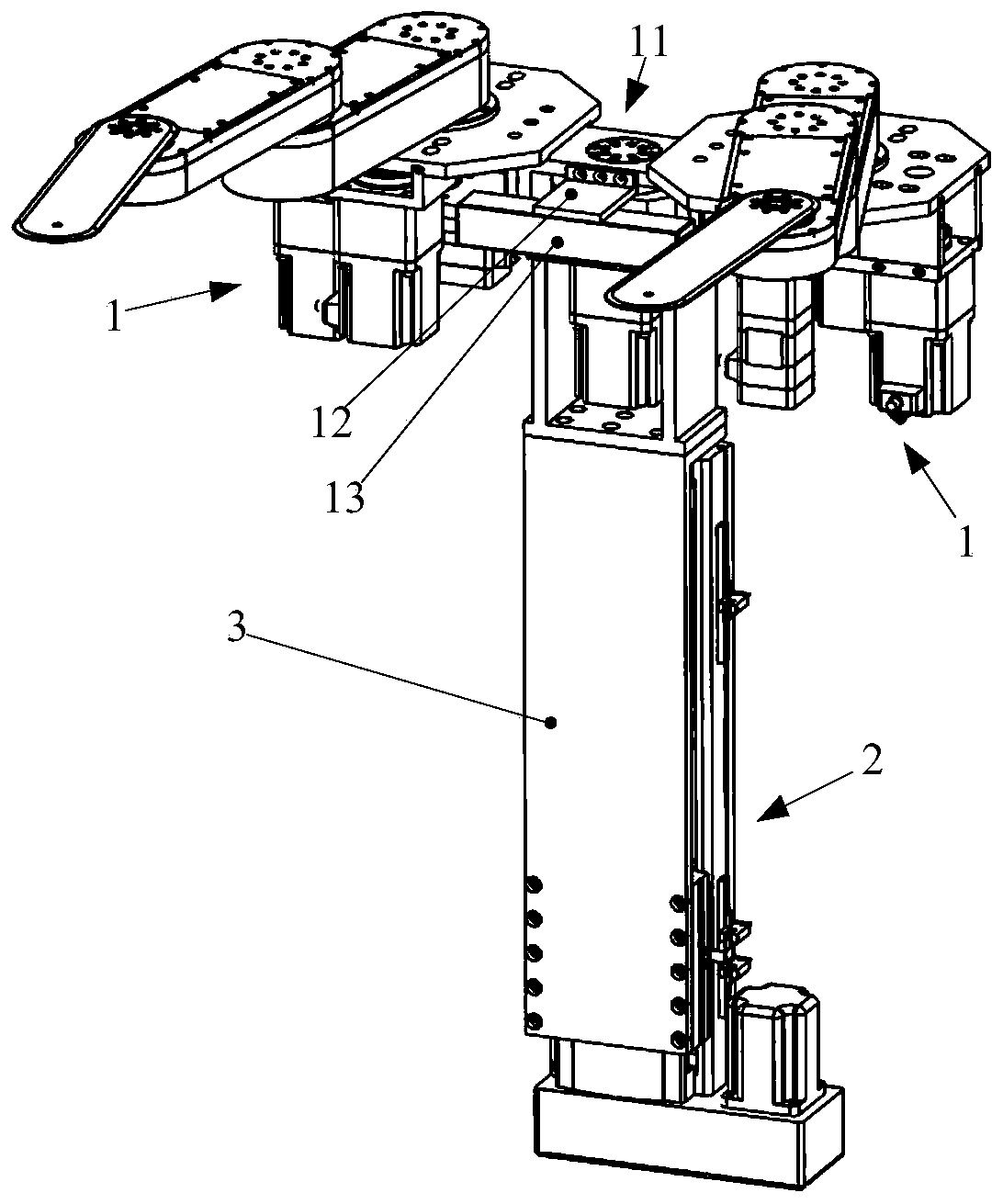

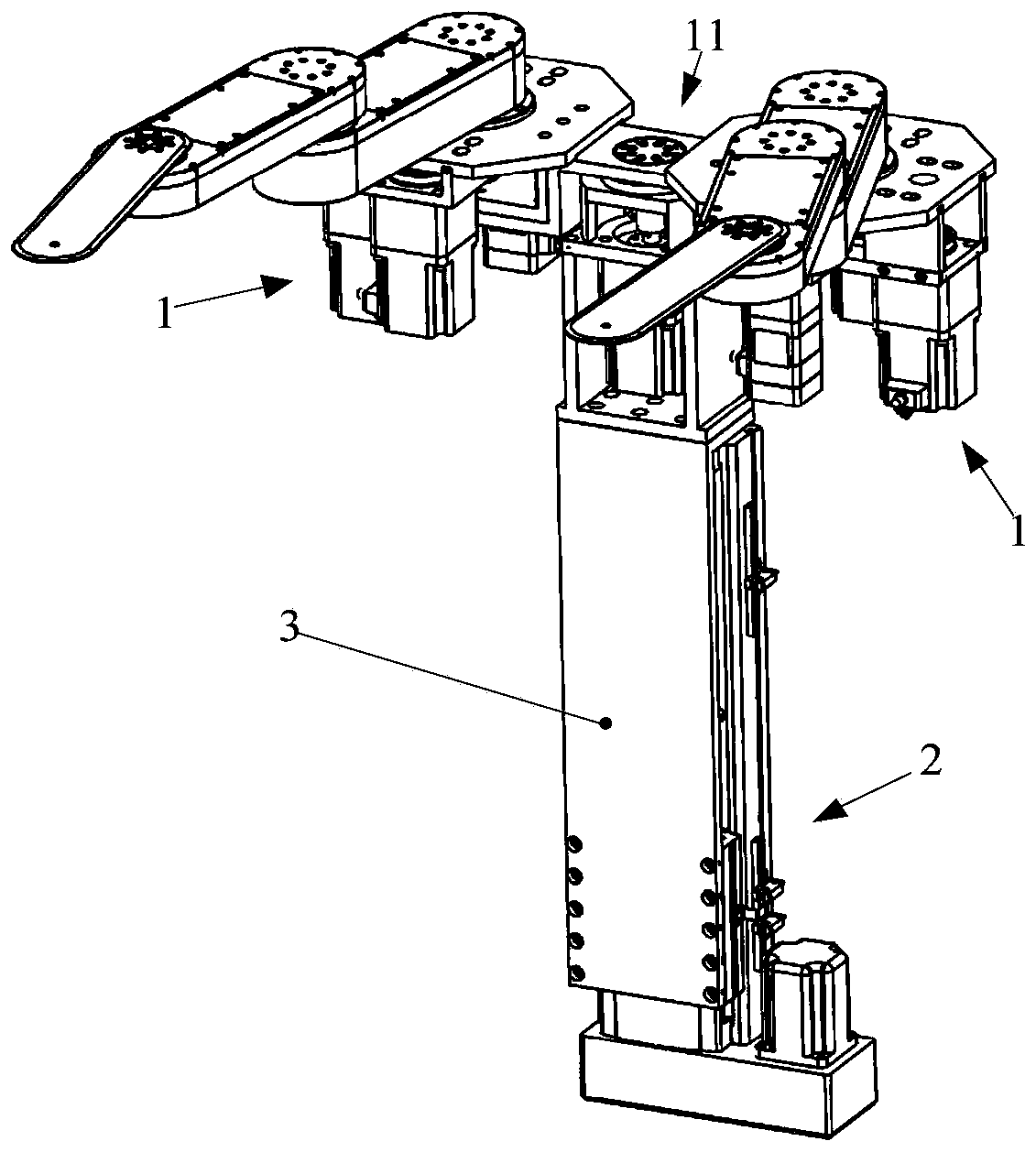

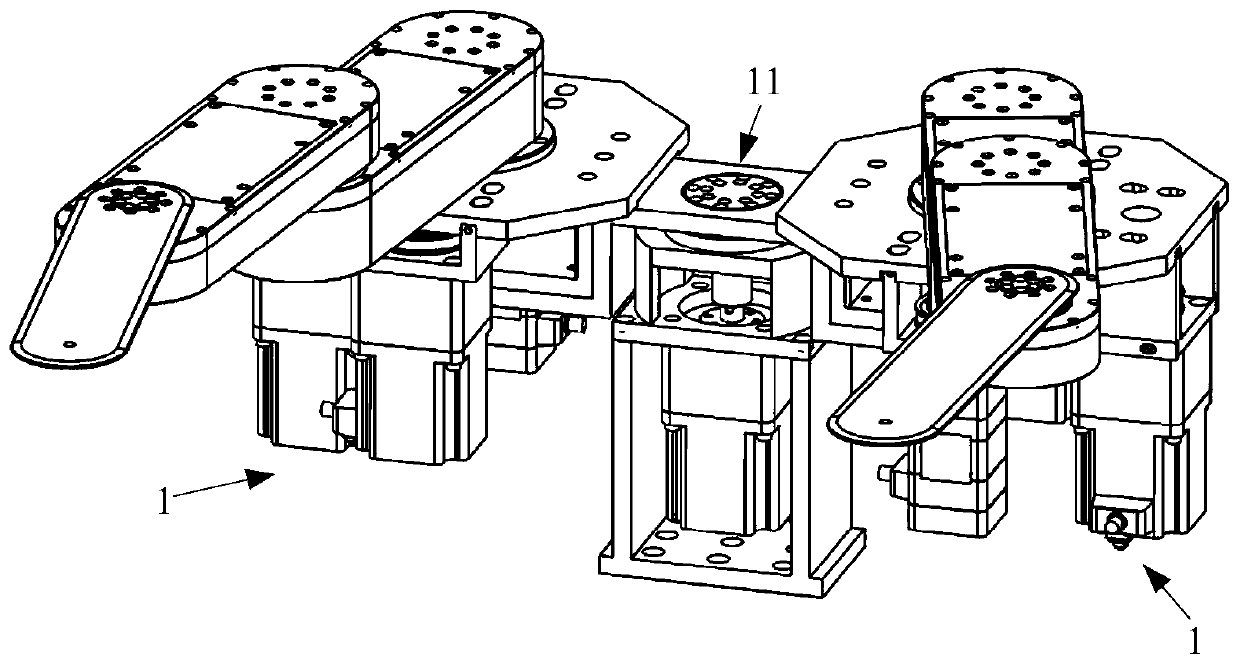

The invention discloses a human-like dual-arm cooperative robot based on synchronous pulley transmission, and relates to the field of robots. The human-like dual-arm cooperative robot comprises two SCARA mechanical arms and a lumbar joint mechanism; the two sides of a rotor of the lumbar joint mechanism are each connected with one SCARA mechanical arm; each SCARA mechanical arm comprises a forearm, a middle arm, a last arm, a forearm transmission mechanism, a middle arm transmission mechanism and a last arm transmission mechanism, wherein the forearm, the middle arm and the last arm are arranged in order from front to back, the forearm transmission mechanism is a first-stage transmission mechanism, an output shaft of a motor of the forearm transmission mechanism is connected with a rotating shaft of the front arm through a set of synchronous pulley, the middle arm transmission mechanism is a secondary transmission mechanism, an output shaft of a motor of the middle arm transmission mechanism is sequentially connected to a rotating shaft of the middle arm in a transmitting manner through two sets of synchronous pulleys, the last arm transmission mechanism is a three-stage transmission mechanism, and an output shaft of a motor of the last arm transmission mechanism is sequentially connected with the last arm in a transmitting manner through three sets of synchronous pulleys. Thehuman-like dual-arm cooperative robot has the advantages that the rotating angles of the mechanical arms are not limited and the volume of the mechanical arms is reduced.

Description

technical field [0001] The invention relates to the field of robots, in particular to a humanoid dual-arm collaborative robot based on synchronous pulley transmission. Background technique [0002] The planar articulated SCARA robot has three degrees of freedom in rotation and one degree of freedom in the vertical direction. It can quickly locate and complete specified tasks in the horizontal plane. It is especially suitable for assembling printed circuit boards and electronic components, moving and picking up integrated circuit boards, etc. Work, is widely used in plastics industry, automobile industry, electronics industry, pharmaceutical industry and food industry and other fields. [0003] The traditional SCARA robot is driven by direct drive, which has the characteristics of low price, but the motor is located in each joint, and the cable routing makes the rotation angle of the joint limited; the vertical space of the end arm is large and cannot be used in the working s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B25J9/10B25J9/16B25J17/00

Inventor 何张强胡祥涛张腊梅李旺徐非骏吴后平时宇航程五四李赞澄赵晖陈帝江

Owner CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com