Enclosed air-cooling fuel cell

A fuel cell and closed technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as the impact on the life of membrane electrode assemblies, achieve the goal of reducing plating area, reducing costs, and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] It should be noted in advance that the proportions, dimensions and deformations of the components in the embodiments are drawn according to the proportions and dimensions that facilitate explanation, rather than actual dimensions, and are not intended to limit the present invention. The innovation of the present invention lies in the optimized design of the structure of a single battery unit, therefore, the following embodiments only use the unit as an example for illustration.

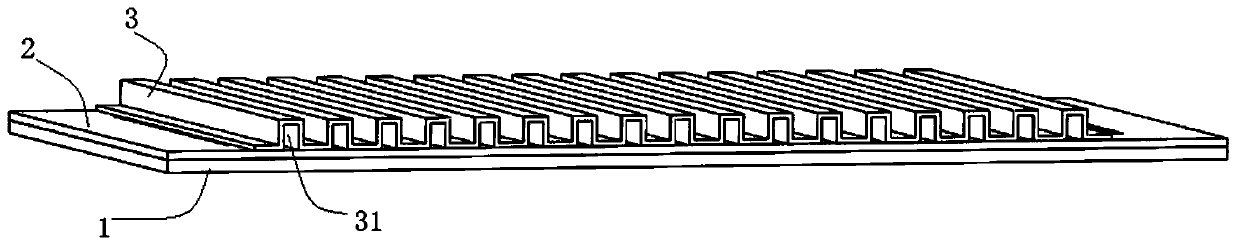

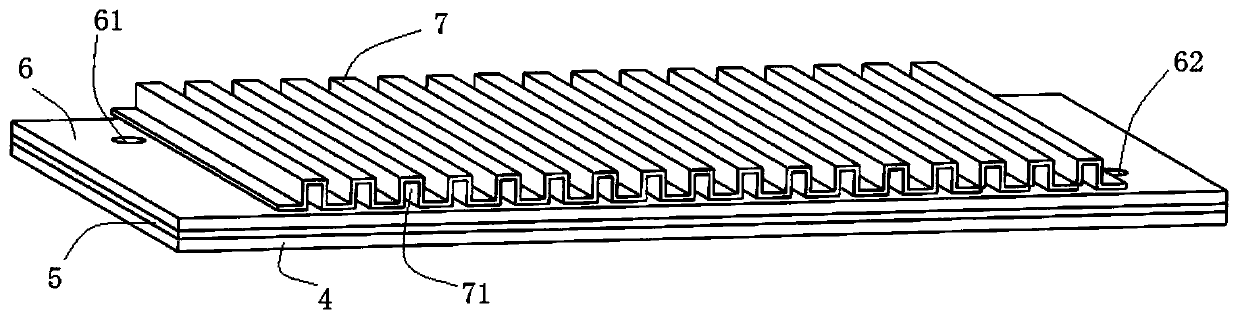

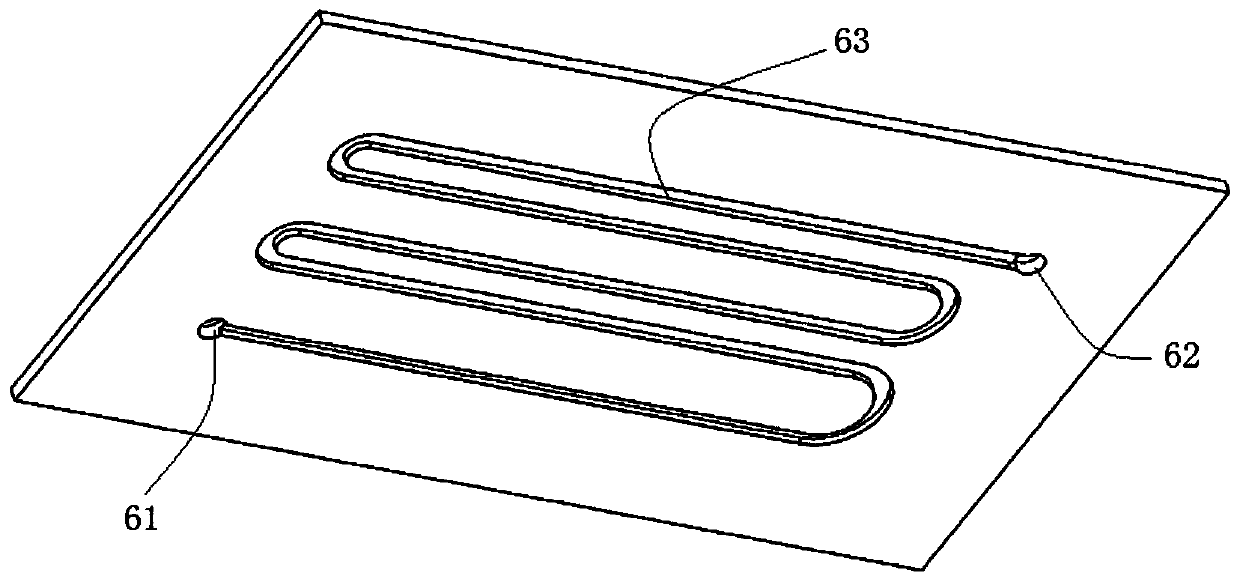

[0028] like Figure 2-Figure 5 As shown, the closed air-cooled fuel cell includes an anode plate 4, a membrane electrode assembly 5, a cathode plate 6, and a heat dissipation plate 7. The membrane electrode assembly 5 is sandwiched between the anode plate 4 and the cathode plate 6, and the heat dissipation plate 7 is stacked. on the cathode plate 6. In this embodiment, it is defined that the cathode plate 6 is above the anode plate 4, and the anode plate 4, the cathode plate 6 and the membrane...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the anode plate adopts the anode plate in the prior art that is not provided with the second airflow channel. When the anode plate and the membrane electrode assembly are stacked, the periphery is glued, and at the same time of sealing and fixing, there is also a gap formed between the anode plate and the middle part of the membrane electrode assembly for air flow to pass through.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that the structure of the cooling plate adopts another structure. Several heat dissipation passages provided by the heat dissipation plate 8, the cross section of a single heat dissipation passage is designed as a trapezoidal groove 81, such as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com