Electric heating type automobile interior foam molding mold

A technology for automotive interior decoration and foam molding, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of reducing processing efficiency, affecting the heat dissipation of the lower mold, and difficult to clean dust, achieving high-efficiency dust-proof dust filters, improving Exhaust heat dissipation performance, easy to replace the dust filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

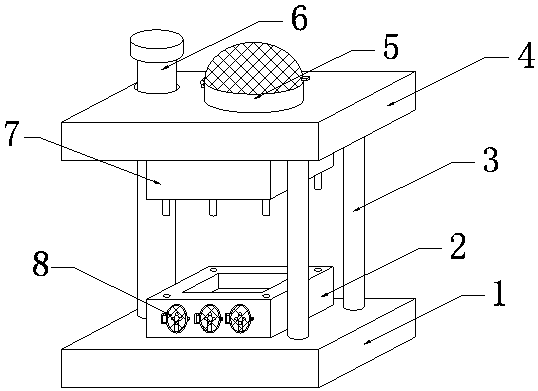

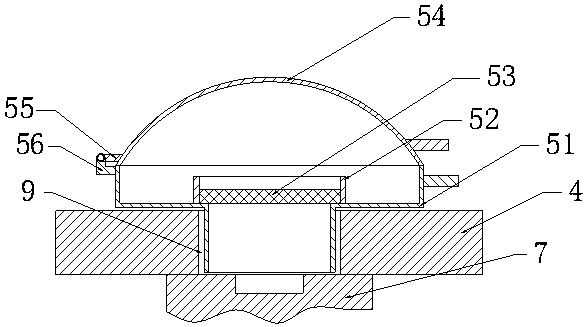

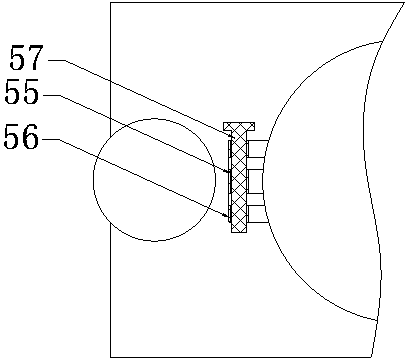

[0022] See Figure 1-Figure 5 , The present invention provides a technical solution: an electrically heated foam molding mold for automobile interior decoration, including a device main body, a dustproof mechanism 5, and a heat dissipation mechanism 8. The device main body includes a lower transverse plate 1, a lower mold 2, a telescopic rod 3, The upper horizontal plate 4, the sliding column 6, the upper mold 7, the upper vent 9 and the lower vent 10, the lower mold 2 is set in the middle of the upper end surface of the upper horizontal plate 4, and the telescopic rod 3 is fixed on the right side of the upper end surface of the lower horizontal plate 1, The sliding column 6 is assembled on the right side of the upper end surface of the lower ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com