Stone machine spindle box saw blade clamping power assisting device

A technology of a power assist device and a spindle box, which is used in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of easy loosening of saw blades, time-consuming and laborious tightening of nuts, etc., and achieve a good effect of preventing saw blades from loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

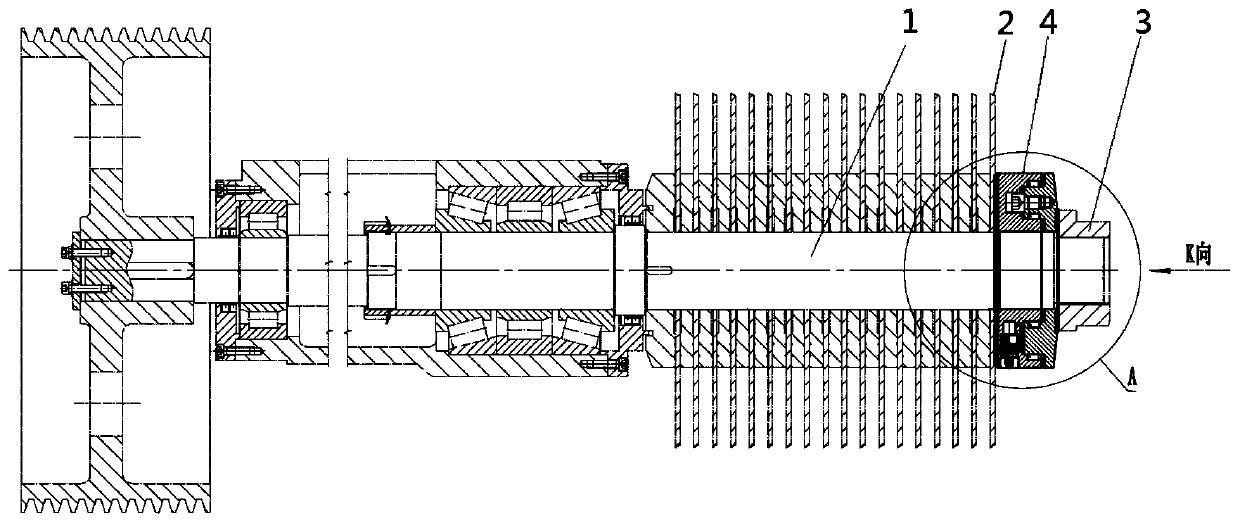

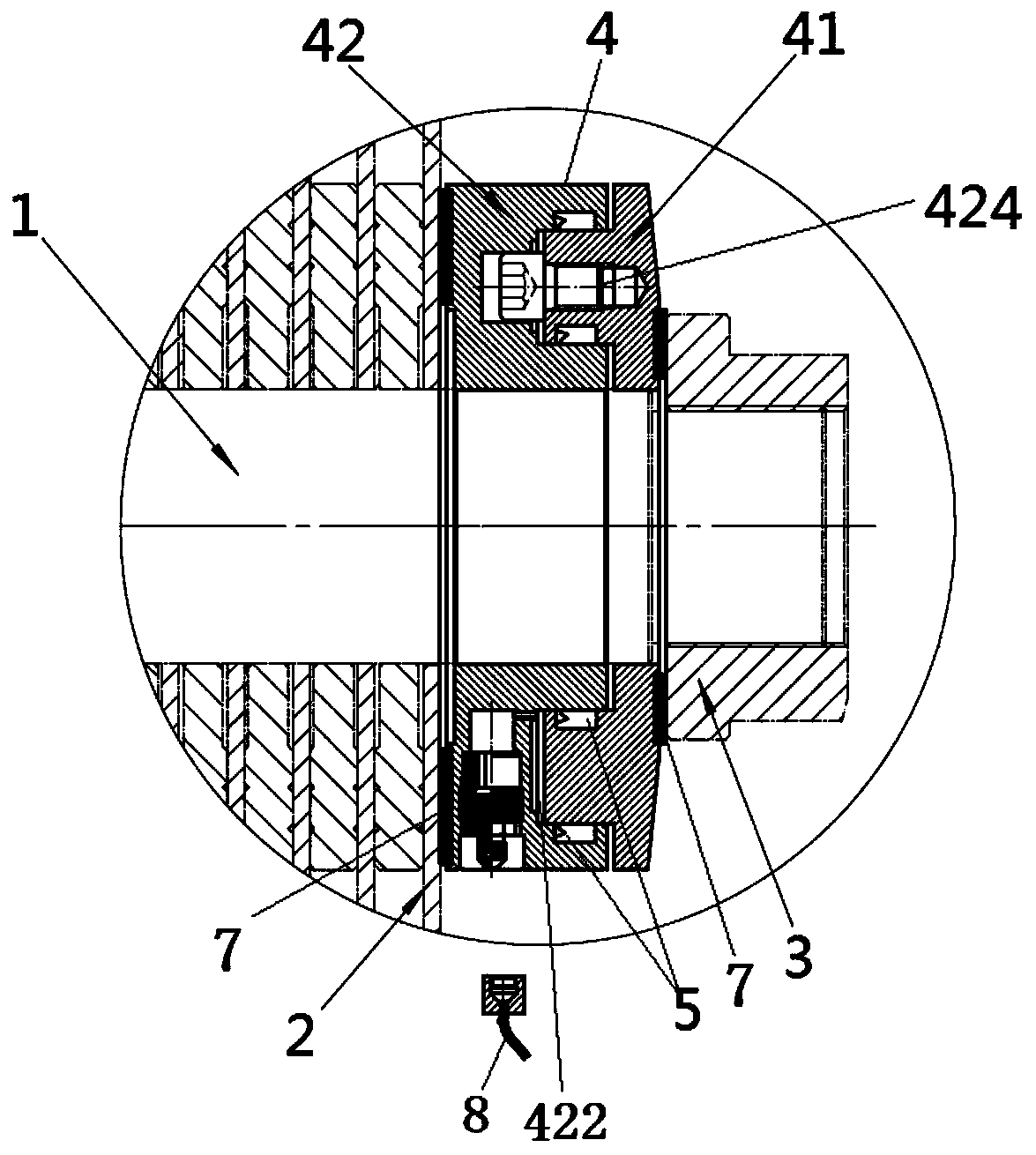

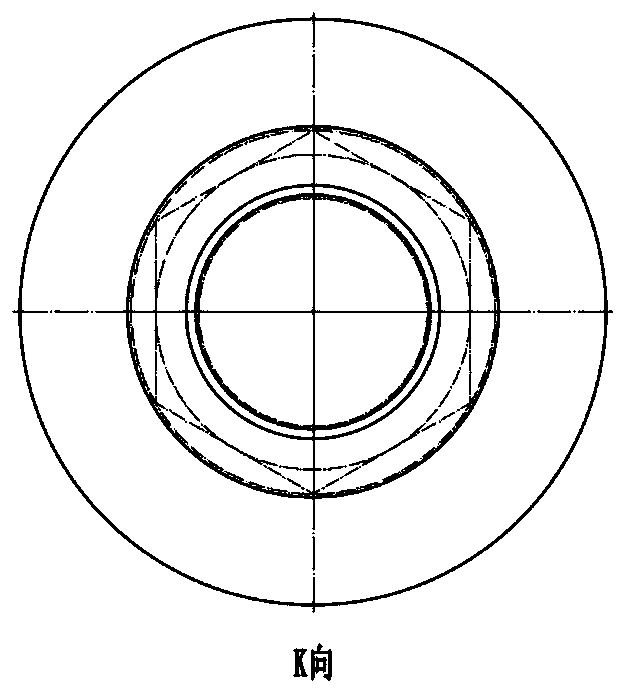

[0036] A stone machine headstock saw blade clamping booster, comprising a stone machine main shaft 1, a saw blade 2 installed on the stone machine main shaft 1, and a device for fastening the saw blade 2 axially along the stone machine main shaft 1 The clamping nut 3 also includes a hydraulic clamping booster 4, the hydraulic clamping booster 4 is arranged on the main shaft 1 of the stone machine between the saw blade 2 and the clamping nut 3, and the hydraulic clamping booster 4 Clamping booster 4 includes A cylinder front cover 41, B cylinder rear cover 42, reverse thrust supercharger assembly 43, pressure regulator assembly 44, oil inlet and outlet assembly 45;

[0037] The front cover 41 of the A cylinder and the rear cover 42 of the B cylinder are both revolving bodies arranged axially through the central hole, and the end face of the A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com