A 4-DOF Parallel Mechanism with Three 3t1r Motion Modes

A degree of freedom and parallel technology, applied in the field of robotics, can solve the problem of no switching and achieve the effect of satisfying one machine with multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

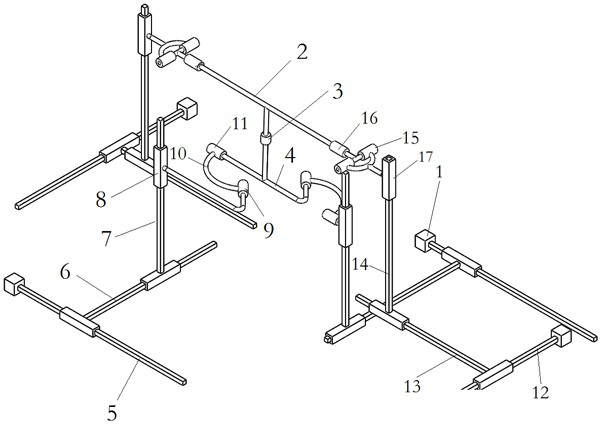

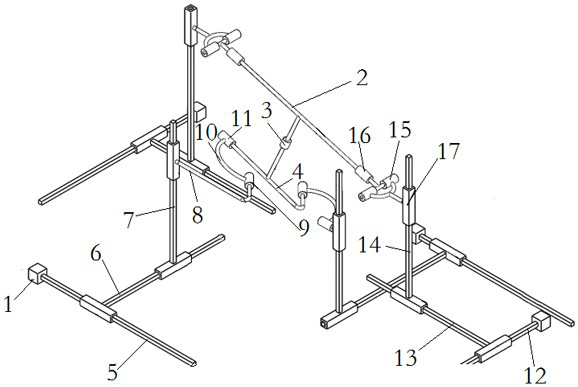

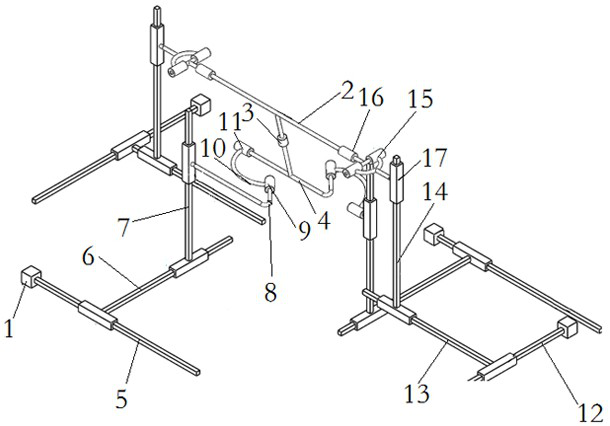

[0029] A four-degree-of-freedom parallel mechanism with three 3T1R motion modes, such as figure 1 As mentioned above, it includes a rod-shaped moving platform 2, and the moving platform 2 passes through the first rotating pair R 1 3 are connected in parallel with a first connecting rod 4,

[0030] It also includes a fixed platform 1, the fixed platform 1 is connected with the first connecting rod 4 through the first branch chain and the third branch chain; Rod 5, each first sliding rod 5 is connected with a T-shaped second connecting rod 6, each second connecting rod 6 includes a connecting rod and a hollow sleeve rod, and the sleeve rod of each second connecting rod 6 Socketed with the corresponding first sliding rod 5, so that each second connecting rod 6 can slide along the corresponding first sliding rod 5 to form the first moving pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com