One-way one-way one-row or two-row variable self-propelled seedling transplanter

A kind of transplanting machine and self-propelled technology, which is applied in the field of seedling transplanting machines and agricultural machinery for seedling transplanting, can solve the problems of high labor intensity, weakening the advantages of seedling transplanting, and high transplanting costs, so as to improve intensification, improve seedling planting efficiency, expand The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

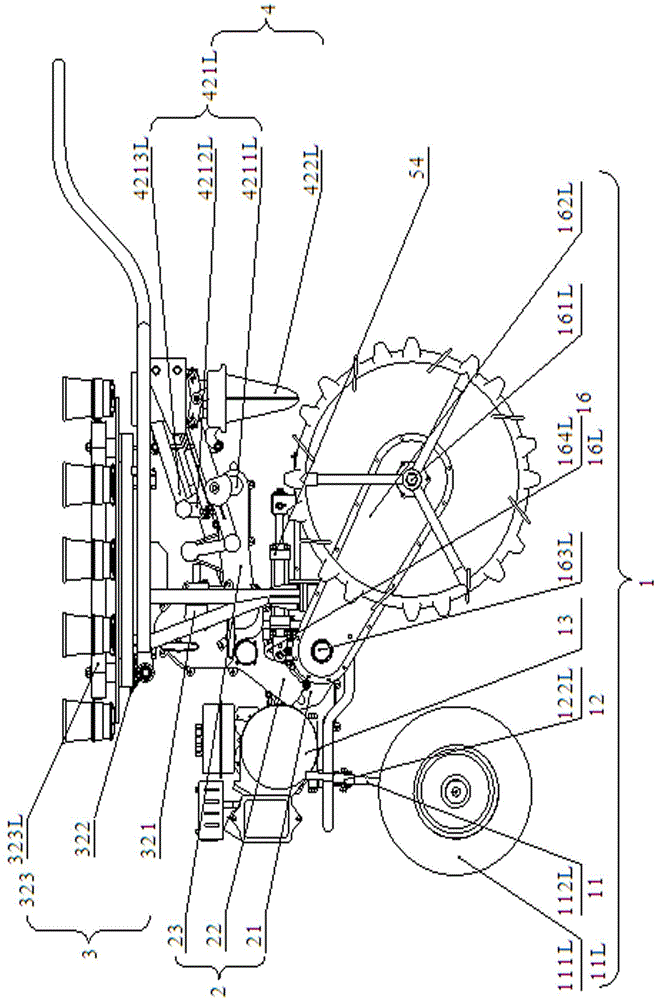

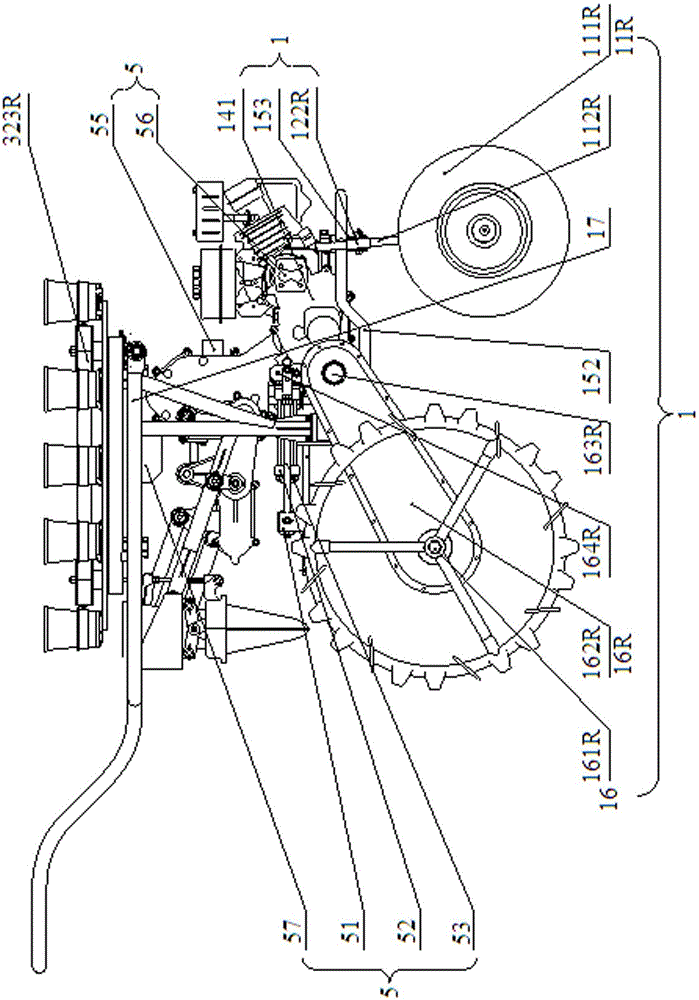

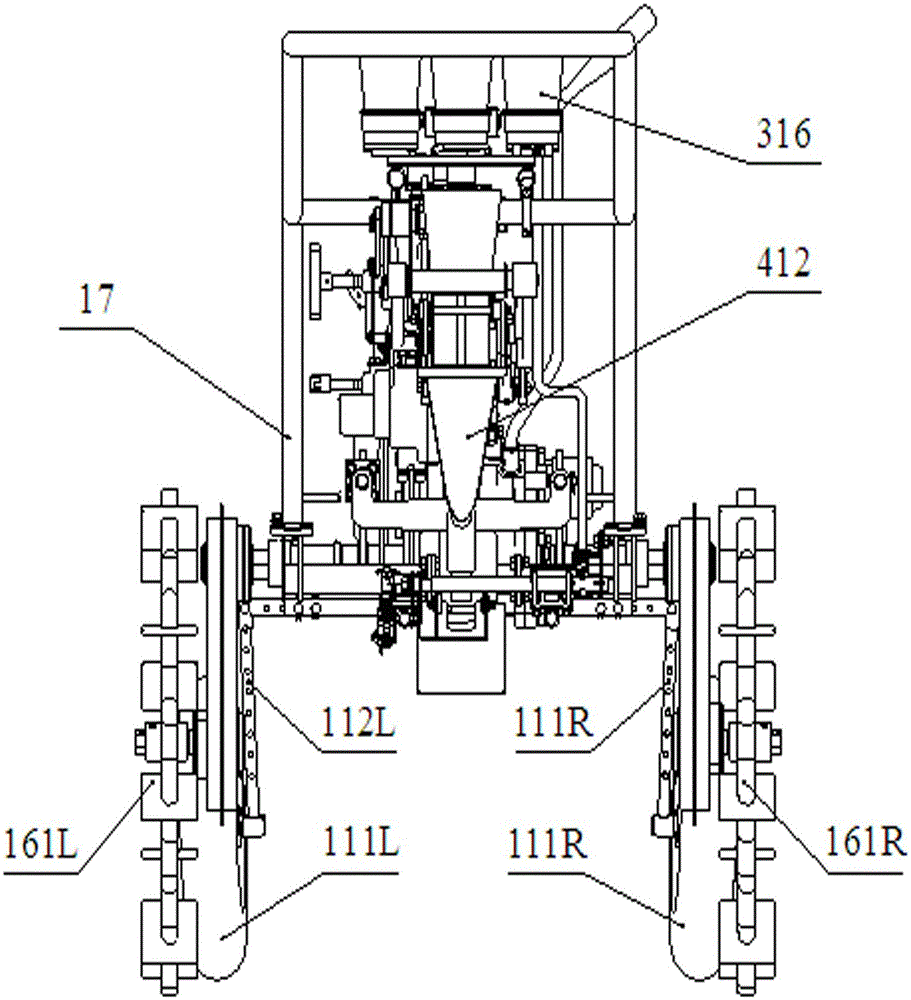

[0042] Example 1 : One-way, one-way, single- and double-row variable self-propelled seedling transplanting machine—two-row embodiment, the composition relationship of this one-way, one-way, two-row, self-propelled seedling transplanting machine is a chassis 1, a power transmission system 2 arranged on the chassis 1, The replaceable double seedling supply system 32 arranged on the chassis 1 and located on the upper part of the power transmission system 2, and the replaceable double seedling supply system 42 installed on the power transmission system 2 and located at the lower part of the replaceable double seedling supply system 32 are arranged on the chassis 1 The hydraulic system 5 located in the middle of the transplanter completes the one-way, one-way, two-row seedling planting operation through the cooperative work of the five parts.

[0043] A front axle 12 and a rear axle 14 are respectively provided at the front and rear of the chassis 1 as described above; a left driv...

Embodiment 2

[0049] Example 2 : One-way, one-way, single-row, single-row, variable self-propelled seedling transplanting machine—one-row embodiment, the composition relationship of this one-way, one-way, single-row, self-propelled seedling transplanting machine is a chassis 1, and a power transmission system 2 arranged on the chassis 1 is arranged on The replaceable single planting system 31 on the chassis 1 and positioned at the top of the power transmission system 2 is installed on the power transmission system 2 and the replaceable single planting system 41 located at the bottom of the replaceable single seedling system 31 is installed on the chassis 1 and The hydraulic system 5 located in the middle of the transplanting machine completes the one-way, one-way, two-row seedling planting operation through the cooperative work of five parts.

[0050] A front axle 12 and a rear axle 14 are respectively provided at the front and rear of the chassis 1 as described above; a left driven wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com