Piezoelectric ultrasonic transducer and working method thereof

A piezoelectric ultrasonic and transducer technology, applied in the direction of fluid using vibration, etc., can solve the problems of weak sensitive signal of piezoelectric ultrasonic transducer, unable to be popularized and applied on a large scale, and unable to be arrayed on a large scale, so as to simplify the process and steps, increased sensitivity, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

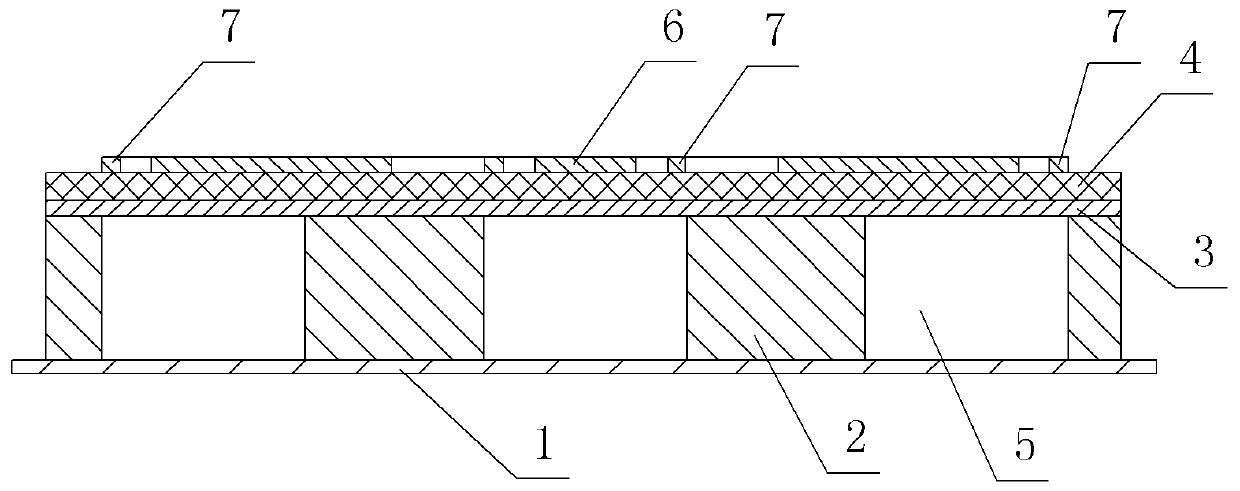

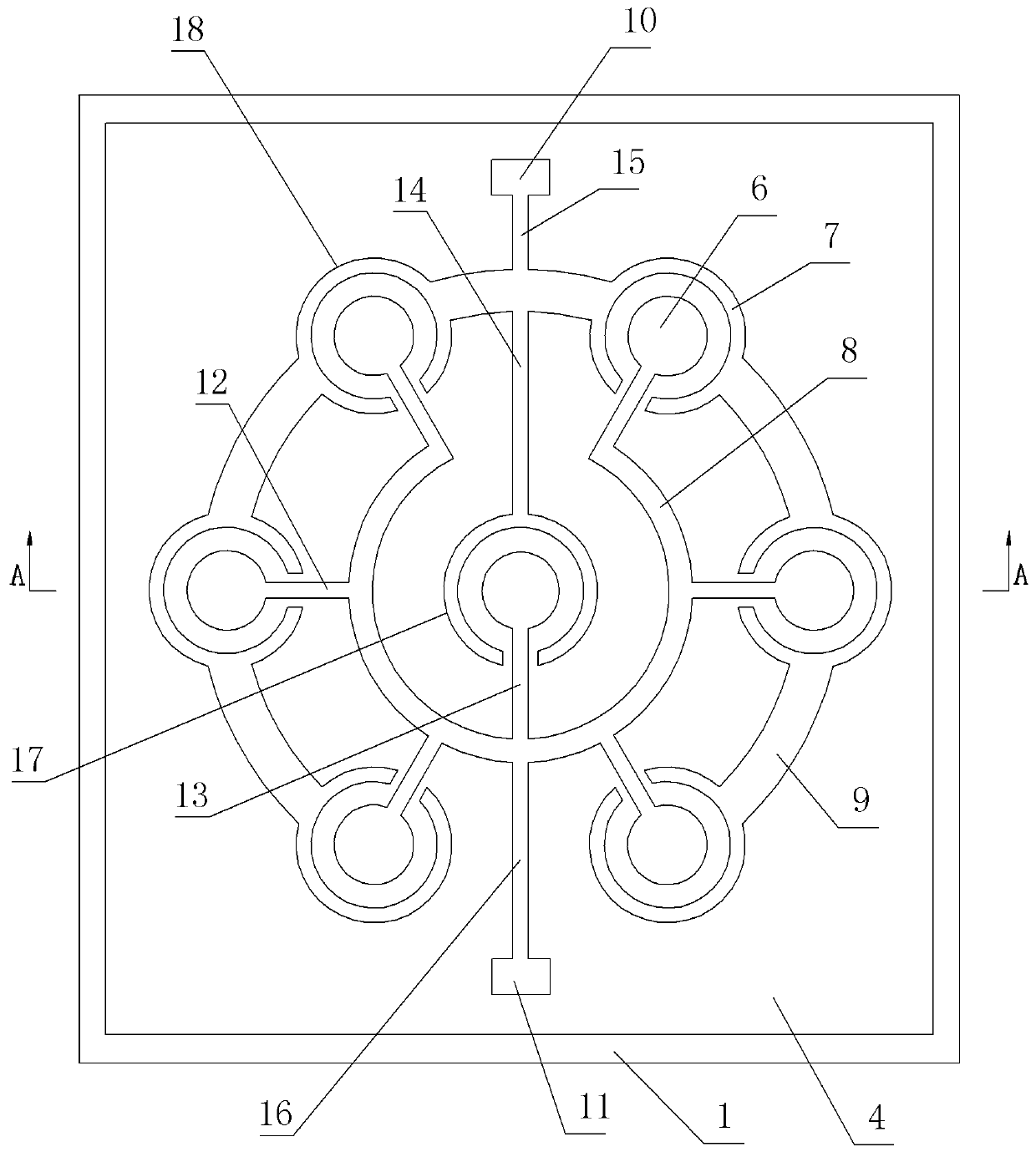

[0037] Embodiment one: if figure 1 ﹑ figure 2 As shown, the piezoelectric ultrasonic transducer includes a top electrode layer, a piezoelectric layer 4, a bottom electrode layer 3, a base layer 2 and a fixed plate 1, the fixed plate 1 is arranged horizontally, and the base layer 2 is arranged on the upper surface of the fixed plate 1 , the bottom electrode layer 3 is arranged on the upper surface of the base layer 2, the piezoelectric layer 4 is arranged on the upper surface of the bottom electrode layer 3, the top electrode layer is arranged on the upper surface of the piezoelectric layer 4, and the top electrode layer contains 7 two identical top electrode units, one of which is the central top electrode unit 17, and the remaining six top electrode units are peripheral top electrode units 18, and the six peripheral top electrode units 18 are evenly distributed around the central top electrode unit 17, The spacing between adjacent top electrode units is half of the waveleng...

Embodiment 2

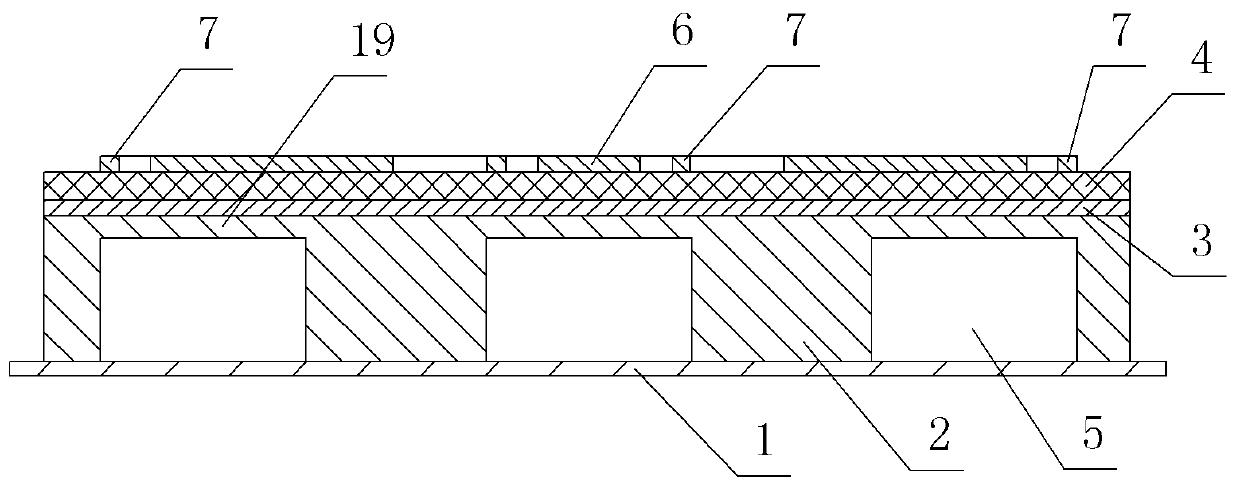

[0058] Embodiment two: if figure 1 ﹑ image 3 As shown, the numbers in the figure are the same as those in Embodiment 1, the representative meanings are the same, and its working process is also basically the same, and the similarities will not be repeated. The difference is: the height of the cavity 5 is less than the height of the base layer 2, and the remaining A part of the base layer 2 above the cavity 5, that is, the cavity 5 stops when the bottom electrode layer 3 is not etched, and a thin film 19 is formed on the cavity 5 as a support to improve the yield and improve the piezoelectricity. The tolerance of the ultrasonic transducer enhances the survivability of the piezoelectric ultrasonic transducer under external damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com