Gravity induction vending machine fixing structure

A vending machine and gravity sensing technology, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., to achieve the effects of stable structure, weight reduction, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

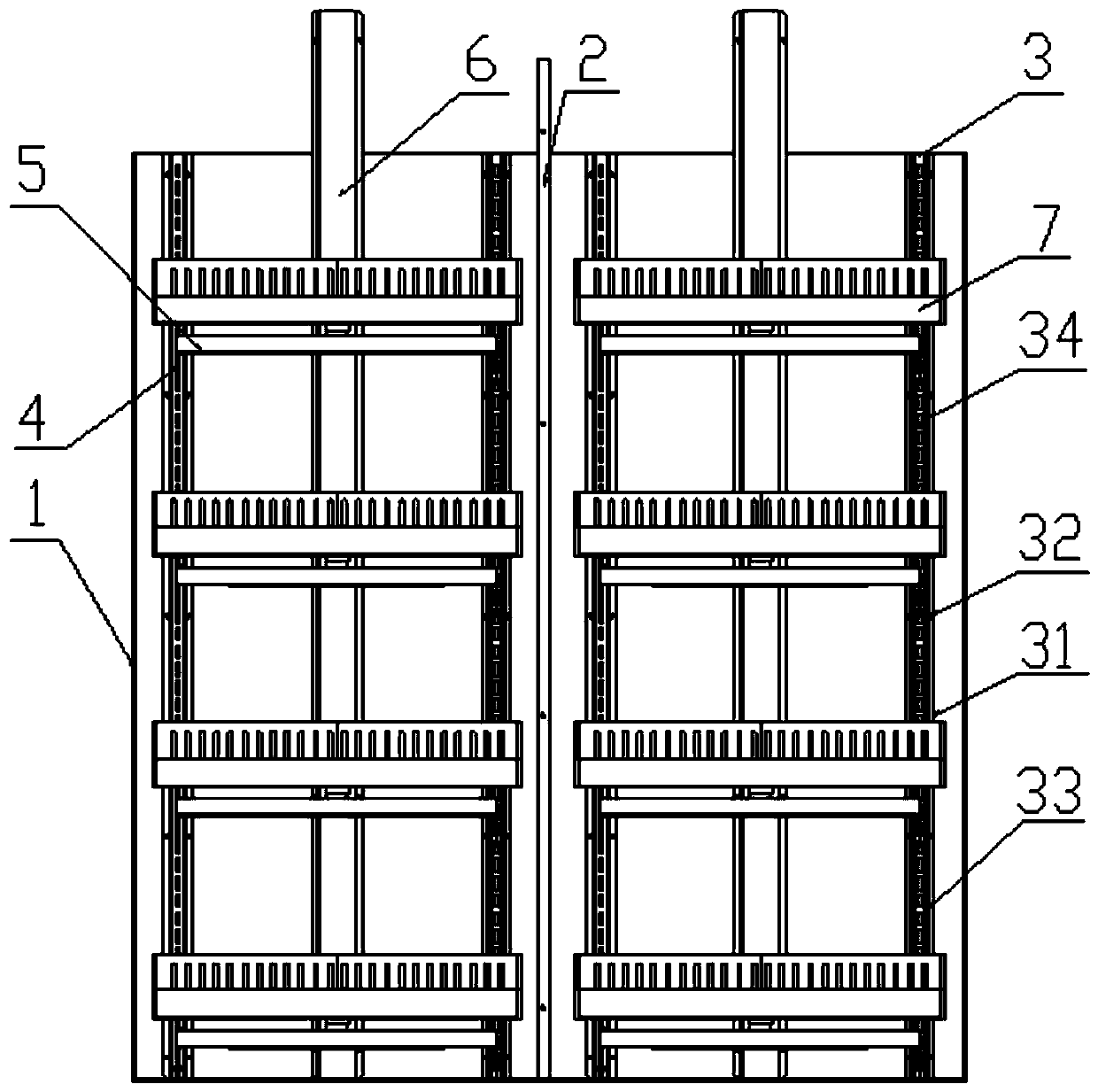

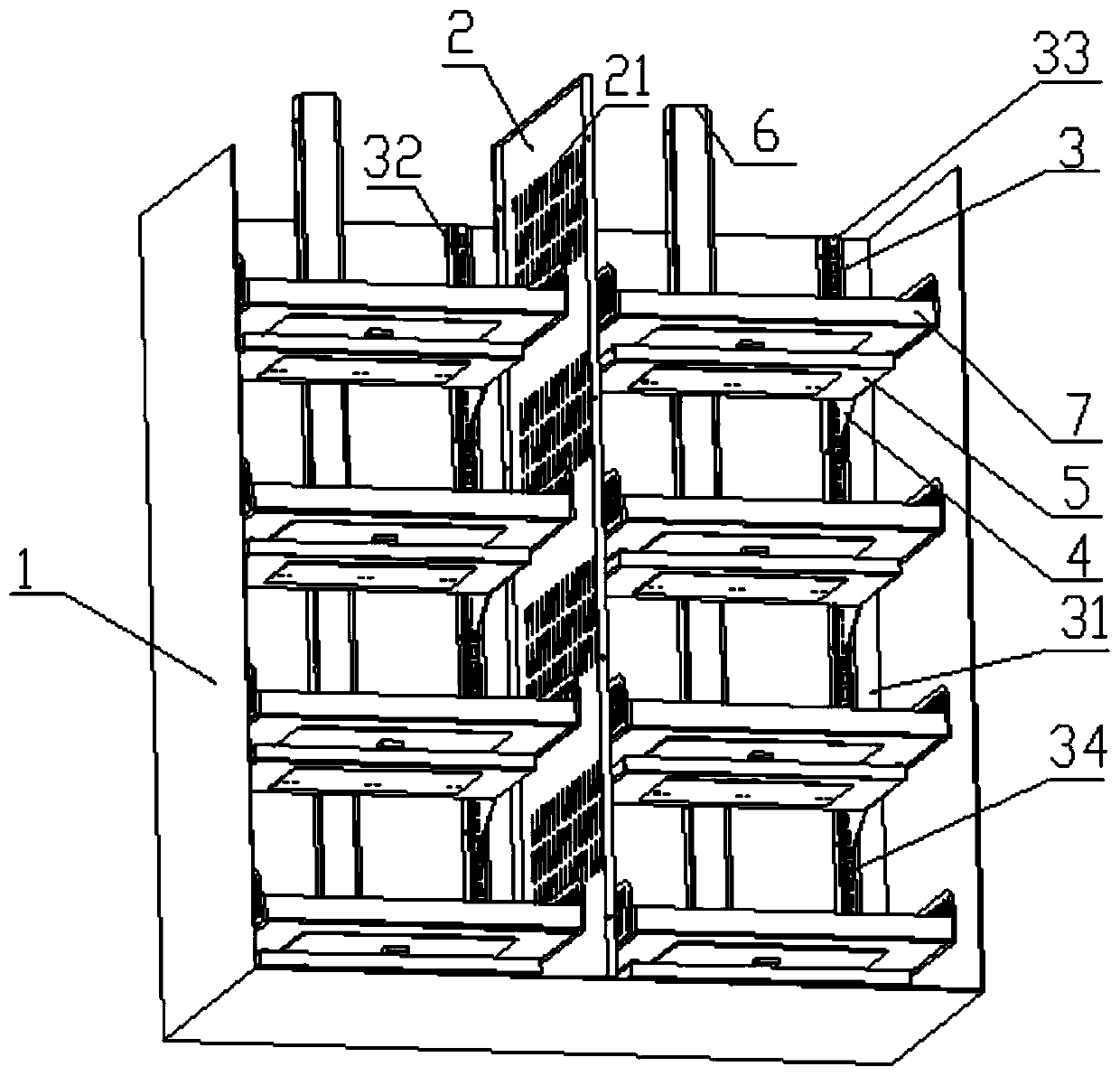

[0026] Such as Figure 1-3 As shown, the present invention provides a fixed structure for a gravity-sensing automatic vending machine, including a vending cabinet main body 1, a partition plate 2, a support rod structure 3 and a clip structure 4; the vending cabinet main body 1 is a rectangular hollow cavity, and the vending cabinet main body 1 The central axis of the inner and rear sides of the vertical vending cabinet body 1 is fixedly connected to the partition plate 2 on the bottom surface of the vending cabinet main body 1, and a number of hollows 21 are evenly distributed on the partition plate 2. The design of the hollowing out 21 reduces the weight of the partition plate 2, thereby reducing the weight of the vending cabinet main body 1 ; The inner rear side of the vending cabinet main body 1 is provided with four sets of support rod structures 3, and the support rod structures 3 are symmetrical to the center of the partition plate 2, thereby providing a stable overall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com