Double-sparking-plug mixed fuel rotor engine and control method thereof

A hybrid fuel, dual spark plug technology, applied in combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of poor fuel economy, high leakage rate, and high emissions, and achieve the effect of improving emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

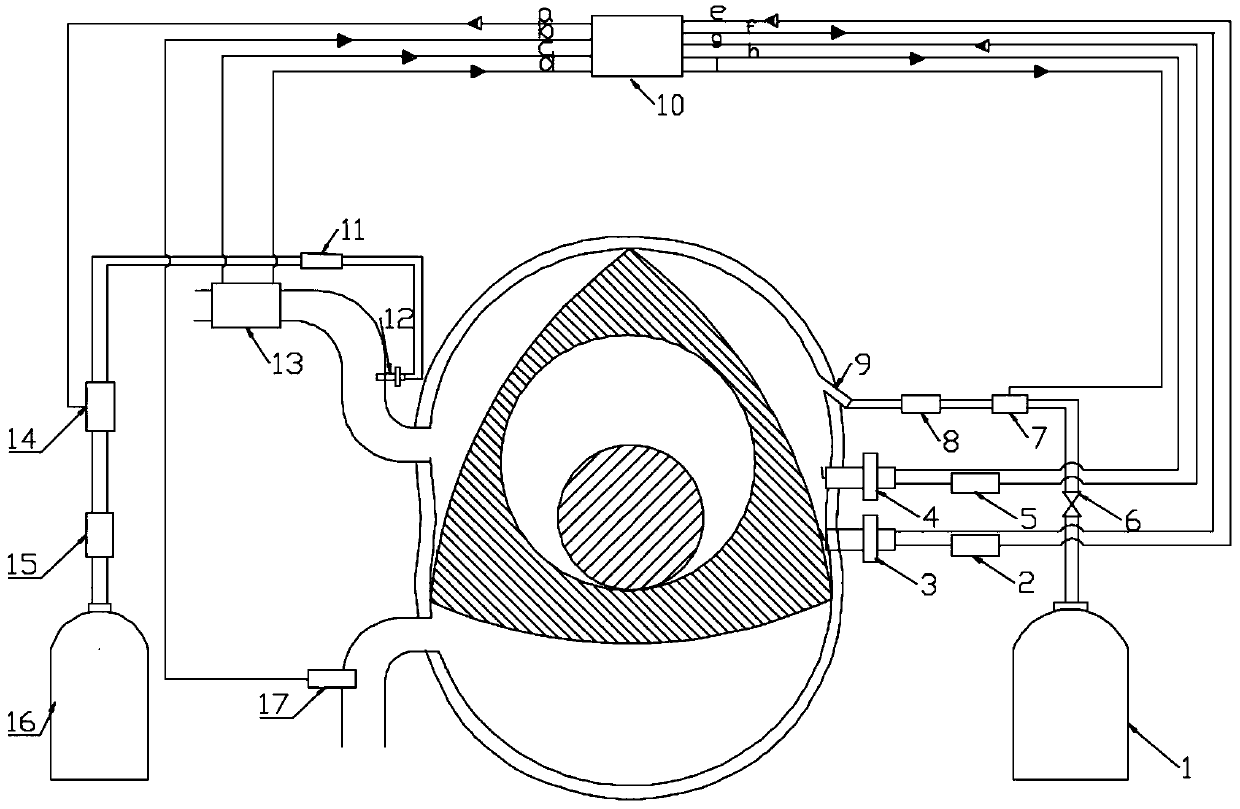

[0024] As shown in the figure (1), it includes: a hydrogen storage tank (1), after the hydrogen comes out of the storage tank, it passes through the pressure reducing valve (6), the hydrogen flow meter (7), and the flame retardant valve (8) successively, and then it is installed in the combustion chamber The hydrogen nozzle (9) on the wall enters the rotor machine for combustion, and the spark plug (3) and the spark plug type cylinder pressure sensor (4) are respectively connected in series with the first charge amplifier (2) and the second charge amplifier (5) and then installed in parallel. On the wall of the combustion chamber, the ECU (10) sends an ignition signal to the first charge amplifier (2) and the second charge amplifier (5) to ignite the spark plug according to the working conditions of the engine, and an air flow meter ( 13) Monitor the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com