Beam and column connecting structure

A beam-column connection and connecting pipe technology, which is applied in the direction of building construction and construction, can solve the problems of easy deformation of the stressed part of the column, affecting the appearance of the beam and column connection, troublesome connection, etc., so as to avoid welding Fixed, high strength, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

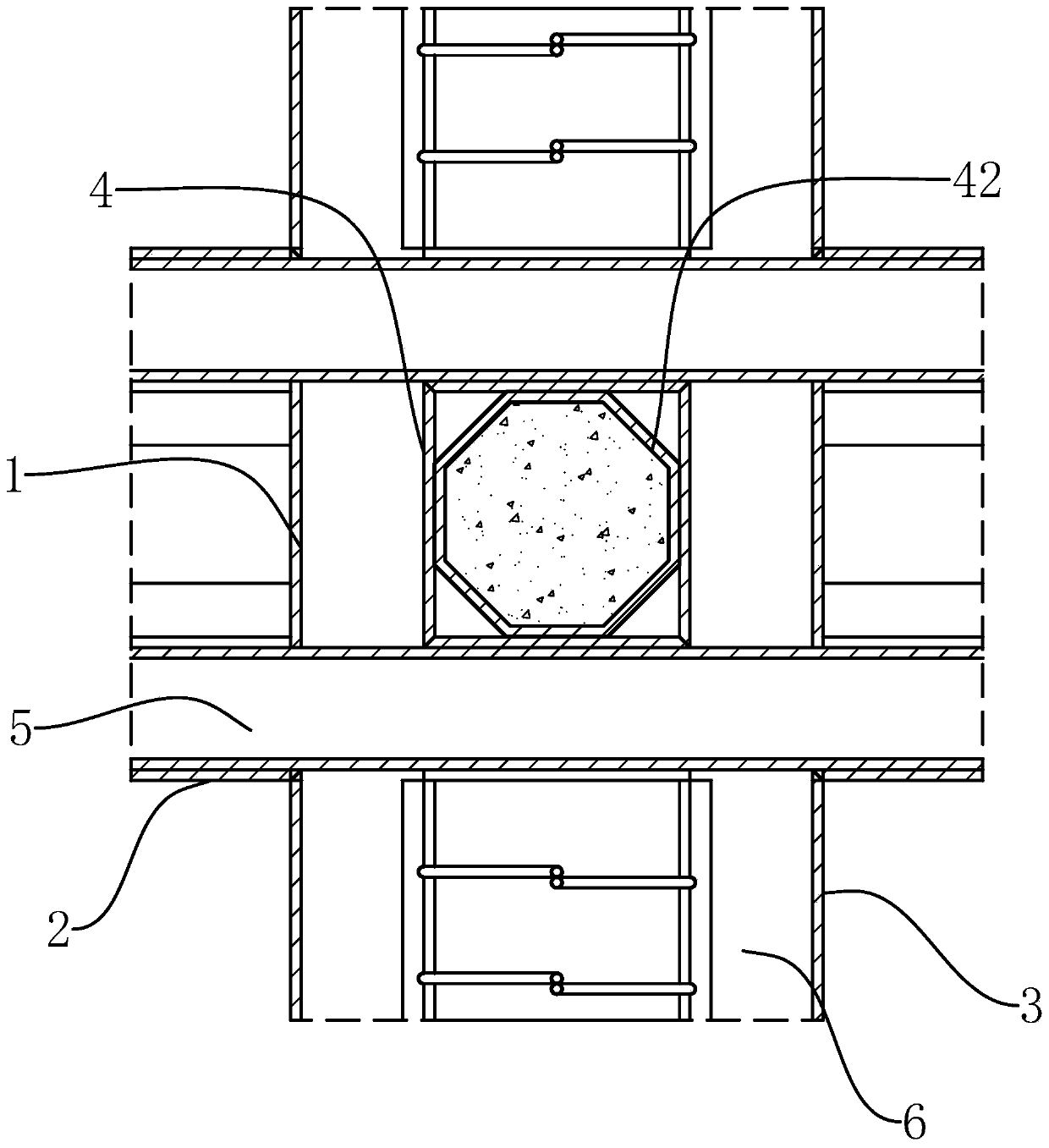

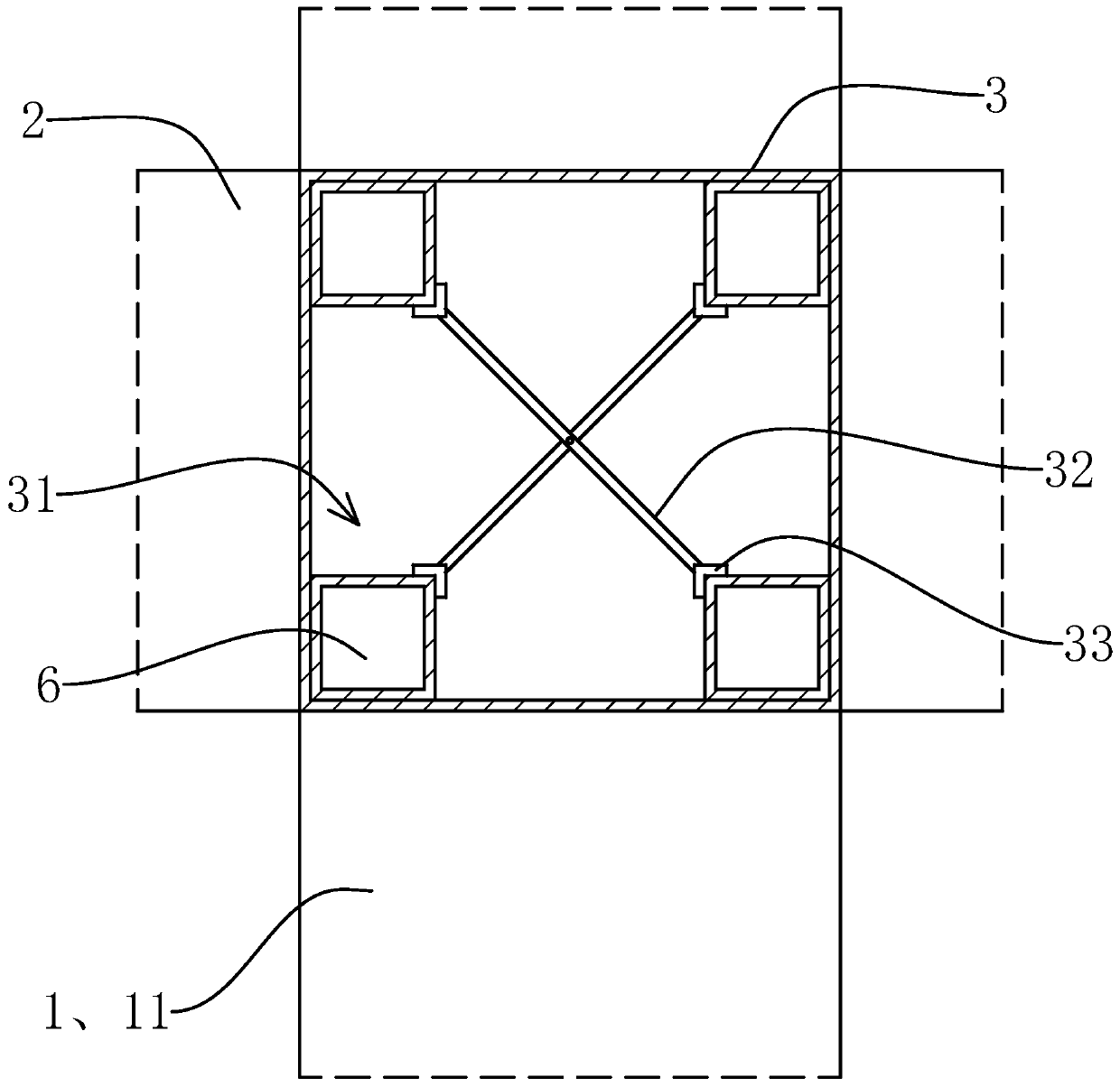

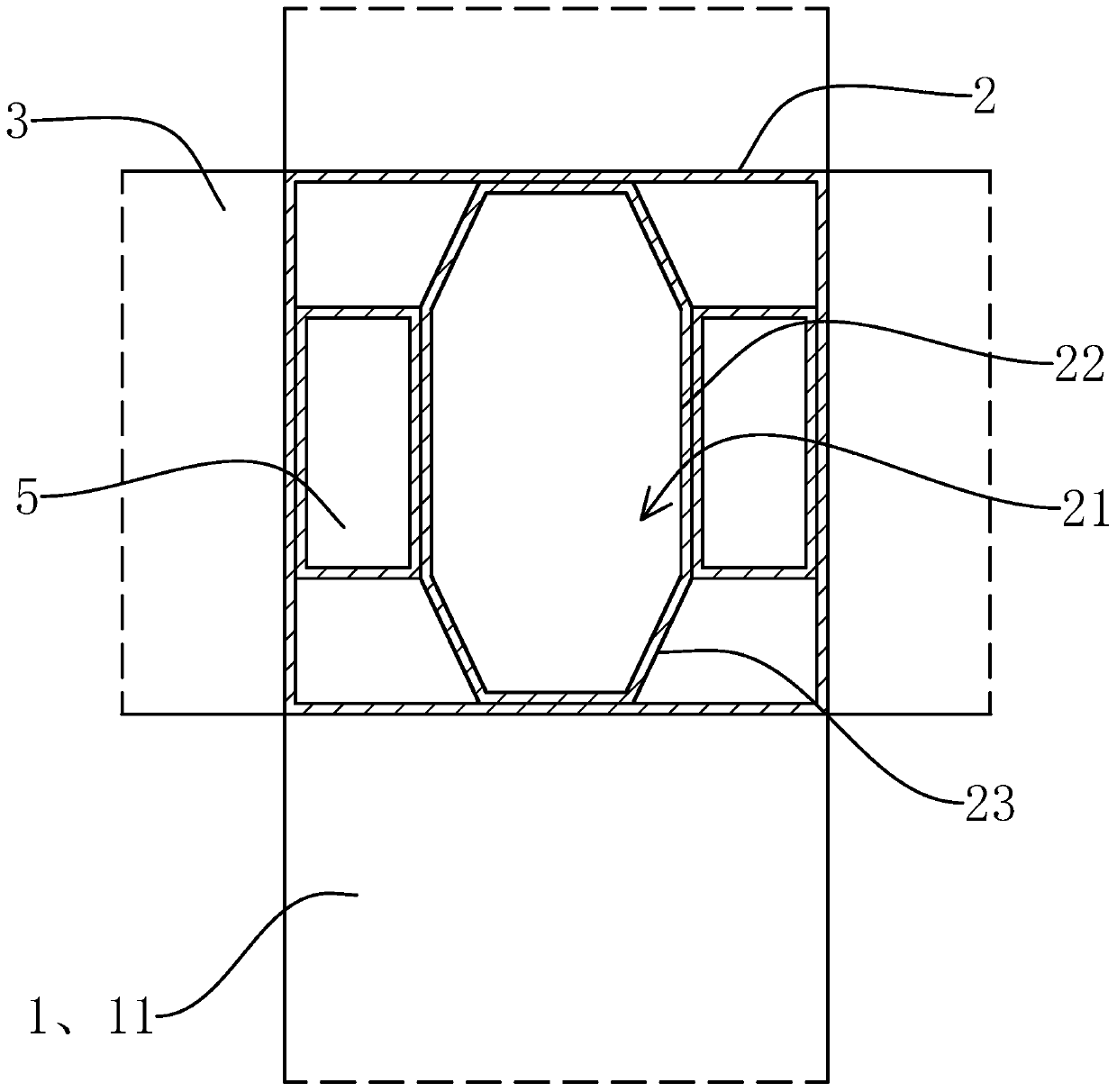

[0030] Such as Figure 1-5 As shown, a beam-column connection structure of the present invention includes a column body and a beam body, the column body includes a column 1, the beam body includes a beam 2 and a longitudinal beam 3, and the column 1, the beam 2 and the longitudinal beam 3 are all hollow rectangular tube structures , and the length direction is perpendicular to each other, the column 1 is vertically arranged, and includes four column plates 11 connected in sequence, two beams 2 and two longitudinal beams 3 are respectively fixed at the same axial position of the column 1, and the two beams 2 Coaxial setting, two longitudinal beams 3 are coaxially arranged, the ends of the two cross beams 2 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com