Retracting and releasing mechanism of binding device

A technology of retractable mechanism and binding device, which is applied in the direction of binding machine parts, etc., can solve problems such as falling off, worm stuck, screw loose, etc., and achieve the effect of fast and smooth axial movement during the switching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

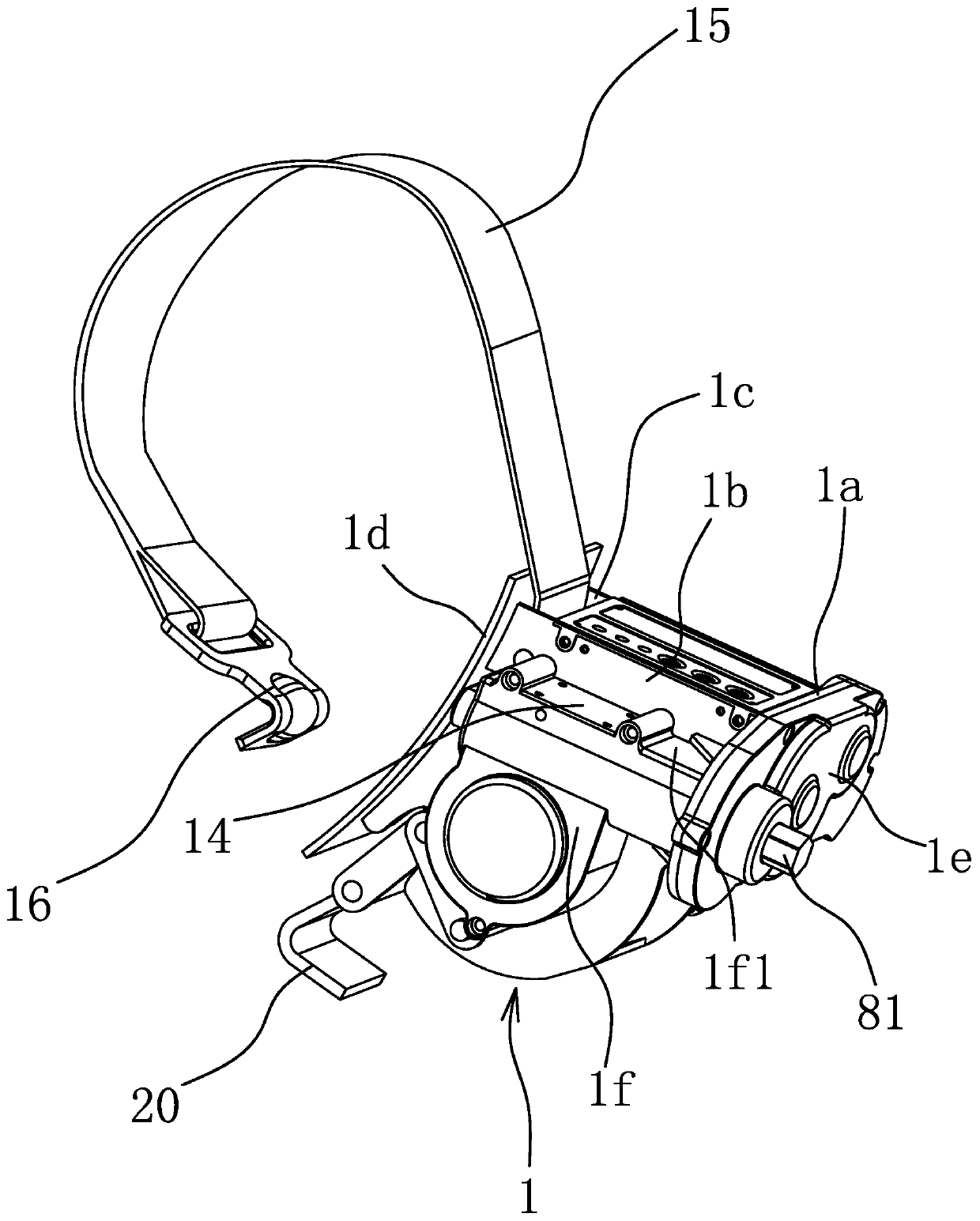

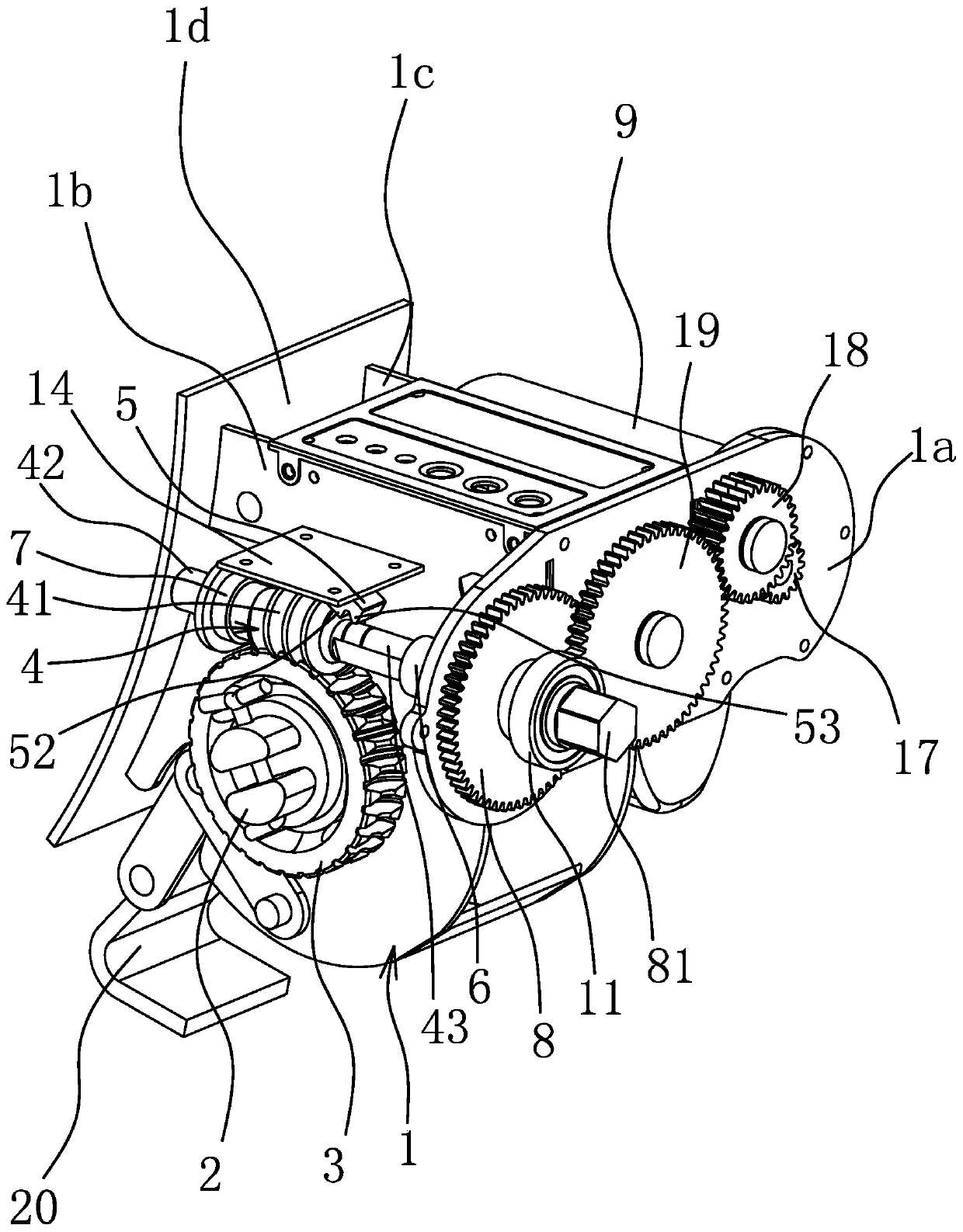

[0045] The binding device in this embodiment is a wheel fixer, which is used to bind and fix the wheels of the vehicle during the transportation of the vehicle, so as to prevent the vehicle from shifting during transportation and ensure the safety of transportation. Of course, the retractable mechanism of the binding device can also be used for other binding equipment, such as a winch or a binding device for binding and fixing goods. Such as figure 1 As shown, the binding device includes a housing 1, a binding member 15 and a reel 2 rotatably arranged on the housing 1, the binding member 15 is a webbing, the webbing is wound on the reel 2, and the protruding end of the webbing is connected with a belt hook 16, A hook 20 is connected to the housing 1 through a chain link. Housing 1 includes abutting plate 1d, mounting plate 1a, side plate 1b, side plate 2 1c, gear cover 1e, worm gear cover 1f, side plate 1b and side plate 2 1c are oppositely arranged, and mounting plate 1a is ...

Embodiment 2

[0060] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the included angle between the pushing plane 521 and the axis of the worm 4 is 25 degrees when the claw 5 swings toward the limit position in the direction close to the worm 4 .

Embodiment 3

[0062] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the included angle between the pushing plane 521 and the axis of the worm 4 is 50 degrees when the claw 5 swings toward the limit position in the direction close to the worm 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com