Coal mine camera protection system with automatic lens replacing, cleaning, dust removing and dust falling functions and application thereof

A technology for automatic replacement and protection of the system, applied in the field of mining equipment, can solve the problems of manual cleaning, time-consuming, laborious, dangerous, and inability to obtain underground information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

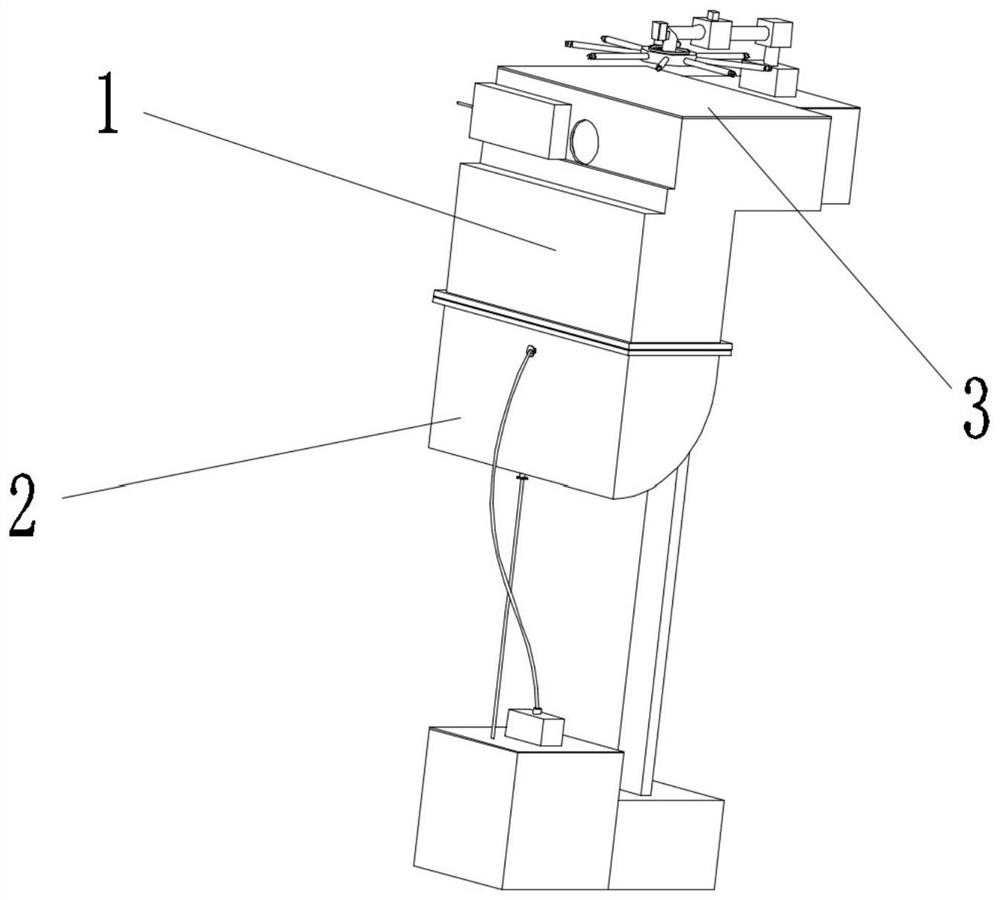

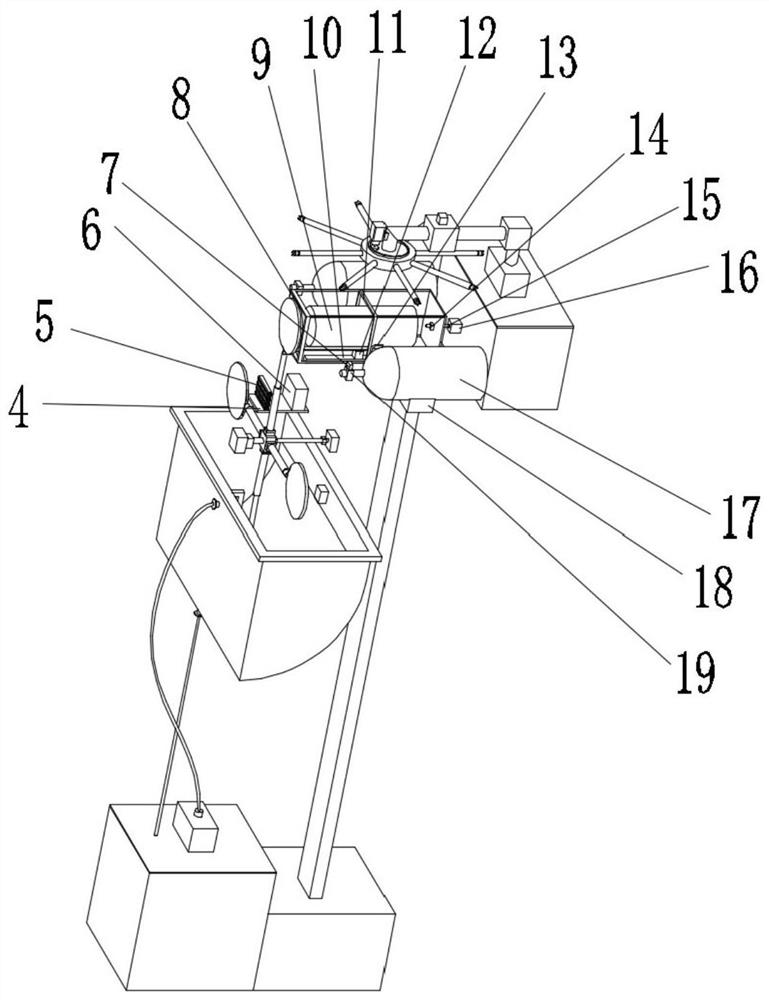

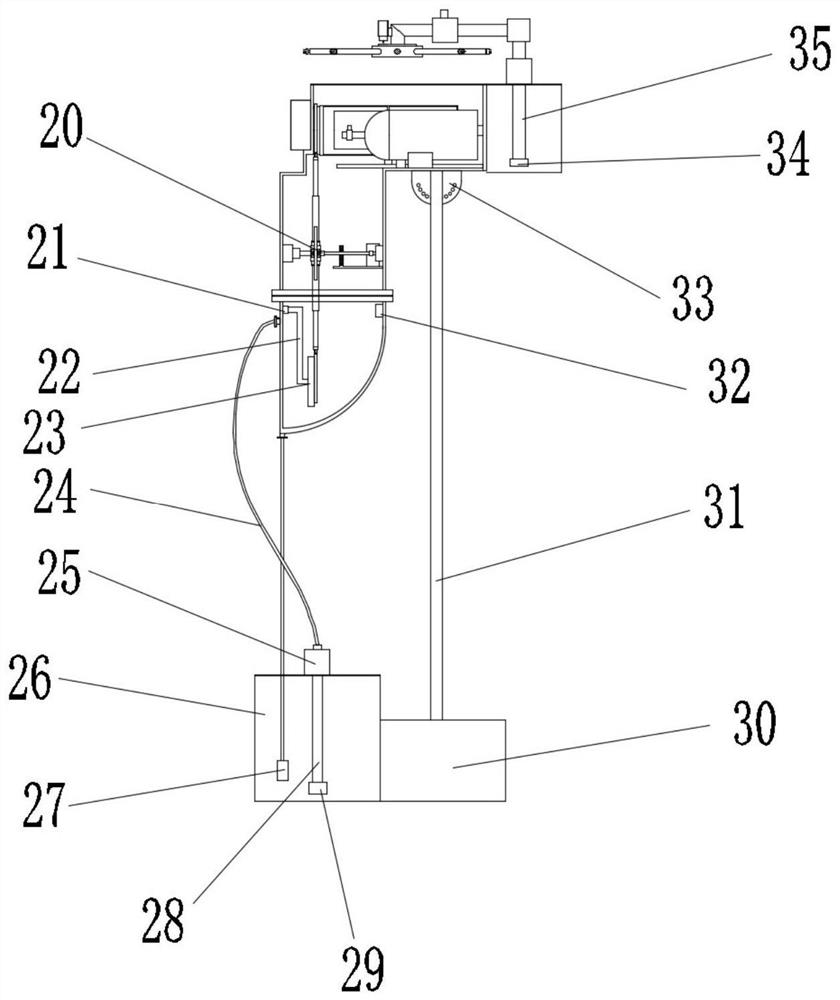

[0058] A camera protection system for coal mines with automatic lens replacement and cleaning and dust removal and dust reduction functions, including: a lens cleaning device, a lens drying device, an internal pressurization device, an external lens cover, a lens bracket, a housing, and a controller;

[0059] The housing includes an upper housing 1 and a lower housing 2. The lens cleaning device cleans the lens in the lower housing, and the lens drying device performs drying of the cleaned lens in the upper housing. At least two A lens is used to replace the working lens and replace it with a new lens when cleaning is required. The camera is located in the upper housing, and the lens of the lens bracket is placed in front of the camera lens; a through hole is provided on the side of the upper housing, and the camera passes through the through hole and the lens to complete the video monitoring work; an external lens cover is set outside the through hole, which is used to seal an...

Embodiment 2

[0072] A camera protection system for coal mines with the functions of automatic lens replacement and cleaning and dust removal. The various devices inside the body are inspected and maintained.

Embodiment 3

[0074] A camera protection system for coal mines with automatic lens replacement and cleaning and dust removal and dust reduction functions. Its structure is as described in Embodiment 1. The difference is that the system also includes a dust suppression device. replacement cycle. The dust suppression device is placed on the outside of the top of the upper shell, and is used to sprinkle water and dust on the outer periphery of the system;

[0075] The dust suppression device includes a second water tank 49, the second water pump 47 is fixedly installed on the water tank cover 48, and each of the two ends of the right-angle water pipe joint 46 is connected with a section of stainless steel water pipe 45, wherein one section of stainless steel water pipe 45 is connected with the second water pump 47, and the other section is connected with the first water pump 47. The electric on-off valve 44 is connected, and the first electric on-off valve 44 stretches out a section of right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com