Sensor-based vehicle tire maintenance system and maintenance method thereof

A maintenance system and sensor technology, applied in tire measurement, vehicle parts, tire parts, etc., can solve the problem of inability to maintain tire pressure, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

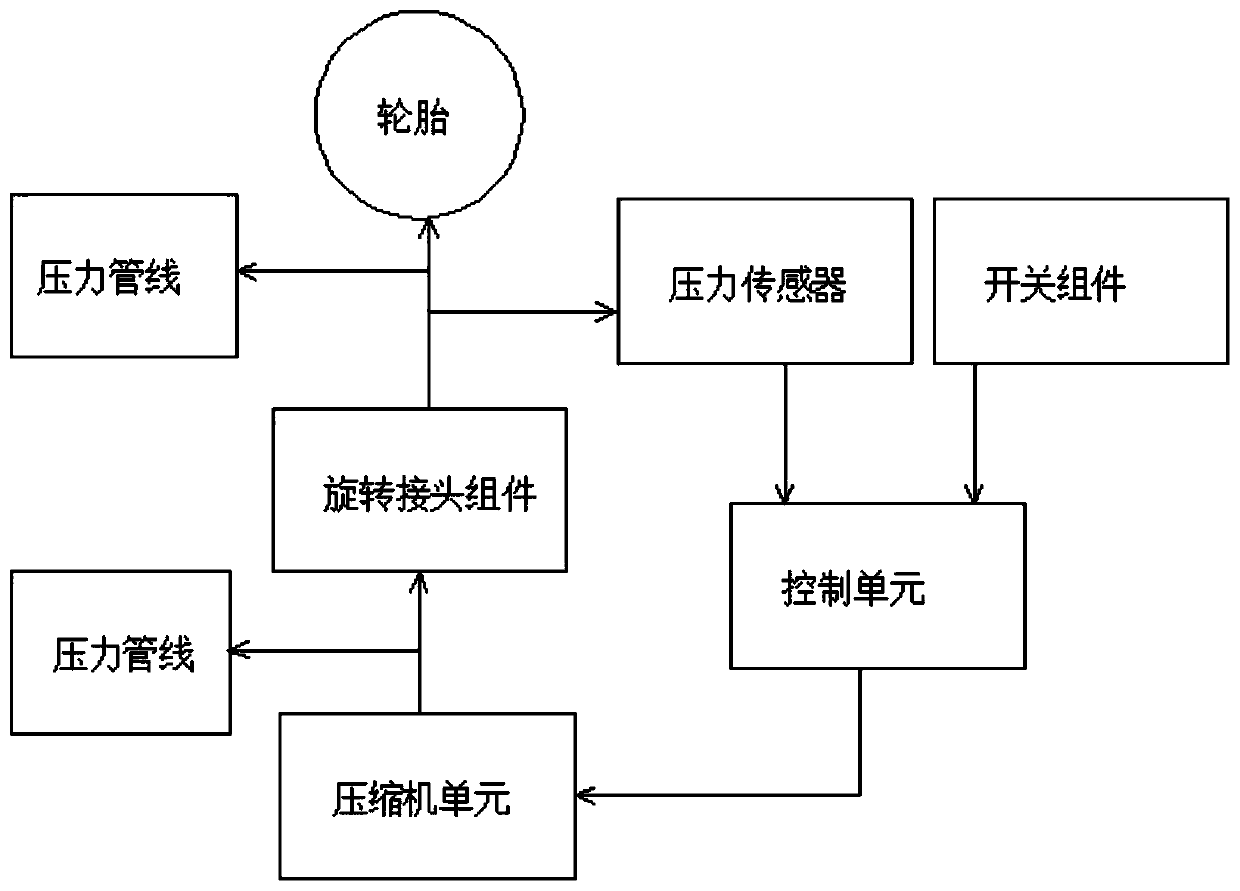

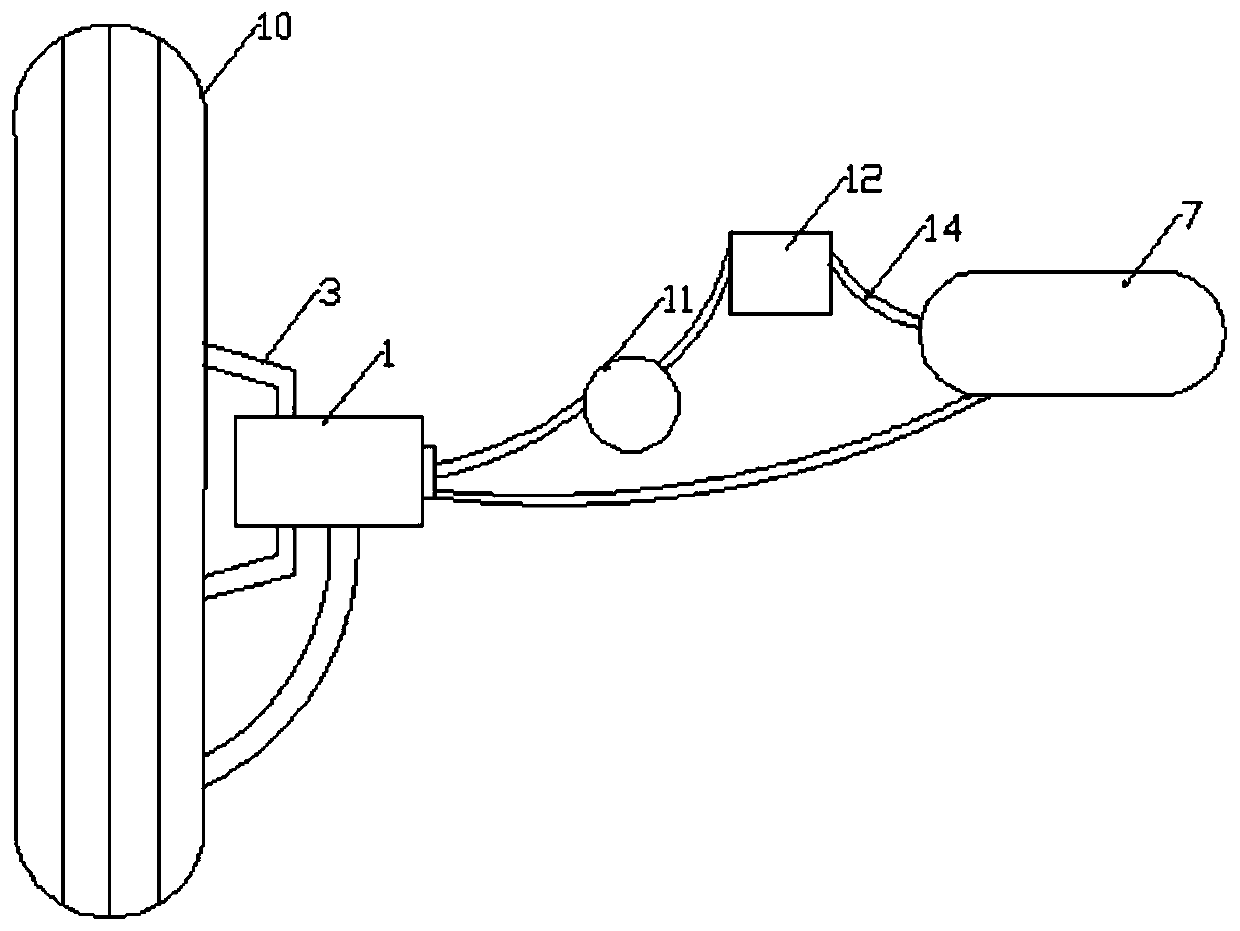

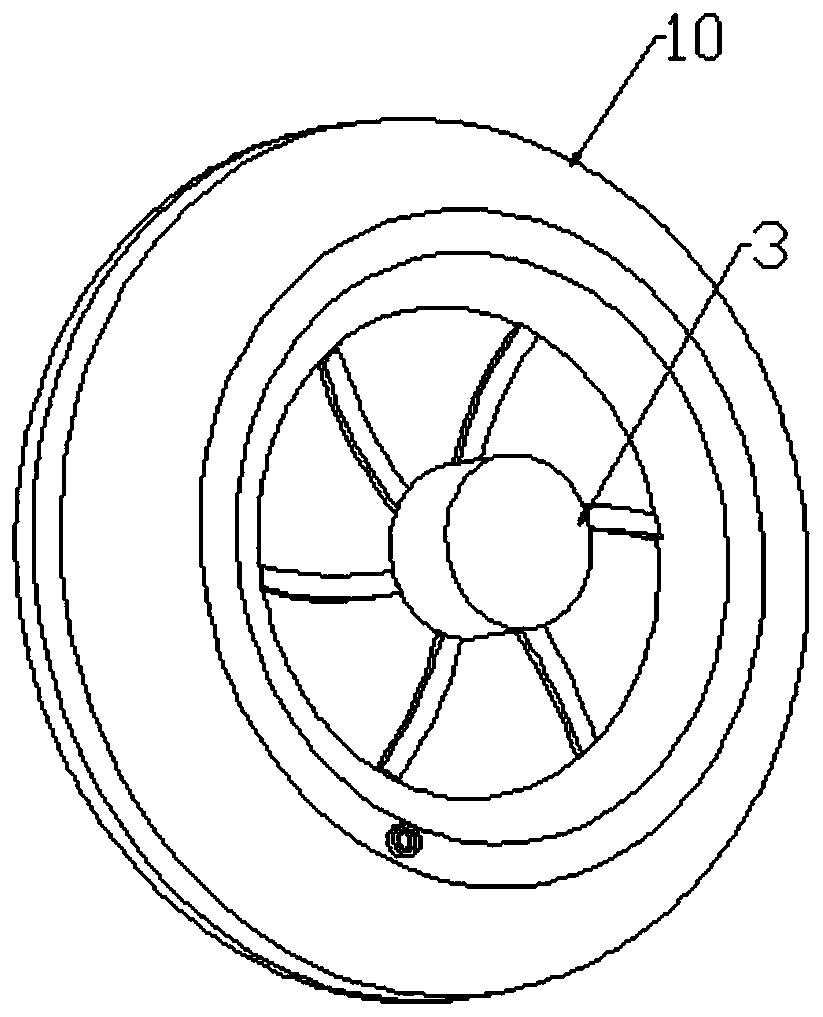

Embodiment 1

[0027] Such as Figure 1 to Figure 7 As shown, a sensor-based vehicle tire maintenance system and its maintenance method include a pressure sensor 11, a control unit 12, a compressor unit 7, a rotary joint assembly 1, a pressure pipeline E and a switch member. The pressure sensor 11 The port is connected to the input end of the control unit 12, the output end of the control unit 12 is connected to the compressor unit 7 through the hose 14, and the port of the compressor unit 7 is connected to the rotary joint assembly 1 through the pressure pipeline E, and the rotary joint assembly 1 Connected to the air valve of the tire through the pressure line E, the switch member is connected to the control unit 12, the rotary joint assembly 1 includes a housing 2, the inner wall of the housing 2 is fixedly connected with an air chamber 4 and a sleeve 5, the The bottom end of the sleeve 5 abuts against the outside of the air cavity 4, and the sleeve 5 is sleeved with a hollow sleeve rod 6...

Embodiment 2

[0035] Such as Figure 1 to Figure 7 As shown, a sensor-based vehicle tire maintenance system and its maintenance method include a pressure sensor 11, a control unit 12, a compressor unit 7, a rotary joint assembly 1, a pressure pipeline E and a switch member. The pressure sensor 11 The port is connected to the input end of the control unit 12, the output end of the control unit 12 is connected to the compressor unit 7 through the hose 14, and the port of the compressor unit 7 is connected to the rotary joint assembly 1 through the pressure pipeline E, and the rotary joint assembly 1 Connected to the air valve of the tire through the pressure line E, the switch member is connected to the control unit 12, the rotary joint assembly 1 includes a housing 2, the inner wall of the housing 2 is fixedly connected with an air chamber 4 and a sleeve 5, the The bottom end of the sleeve 5 abuts against the outside of the air cavity 4, and the sleeve 5 is sleeved with a hollow sleeve rod 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com