Patterning device and patterning method

A patterned, hollow area technology, applied in decorative arts, special decorative structures, processes for producing decorative surface effects, etc., can solve the problem of uneven diffusion of liquid optical glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the description of this disclosure more detailed and complete, reference may be made to the attached drawings and various implementations described below. Elements in the drawings are not drawn to scale and are provided merely to illustrate the present disclosure. Numerous practical details are described below in order to provide a thorough understanding of the present disclosure, however, those of ordinary skill in the relevant art will understand that the present disclosure can be practiced without one or more of the practical details, and thus, these details are not apply to define this disclosure.

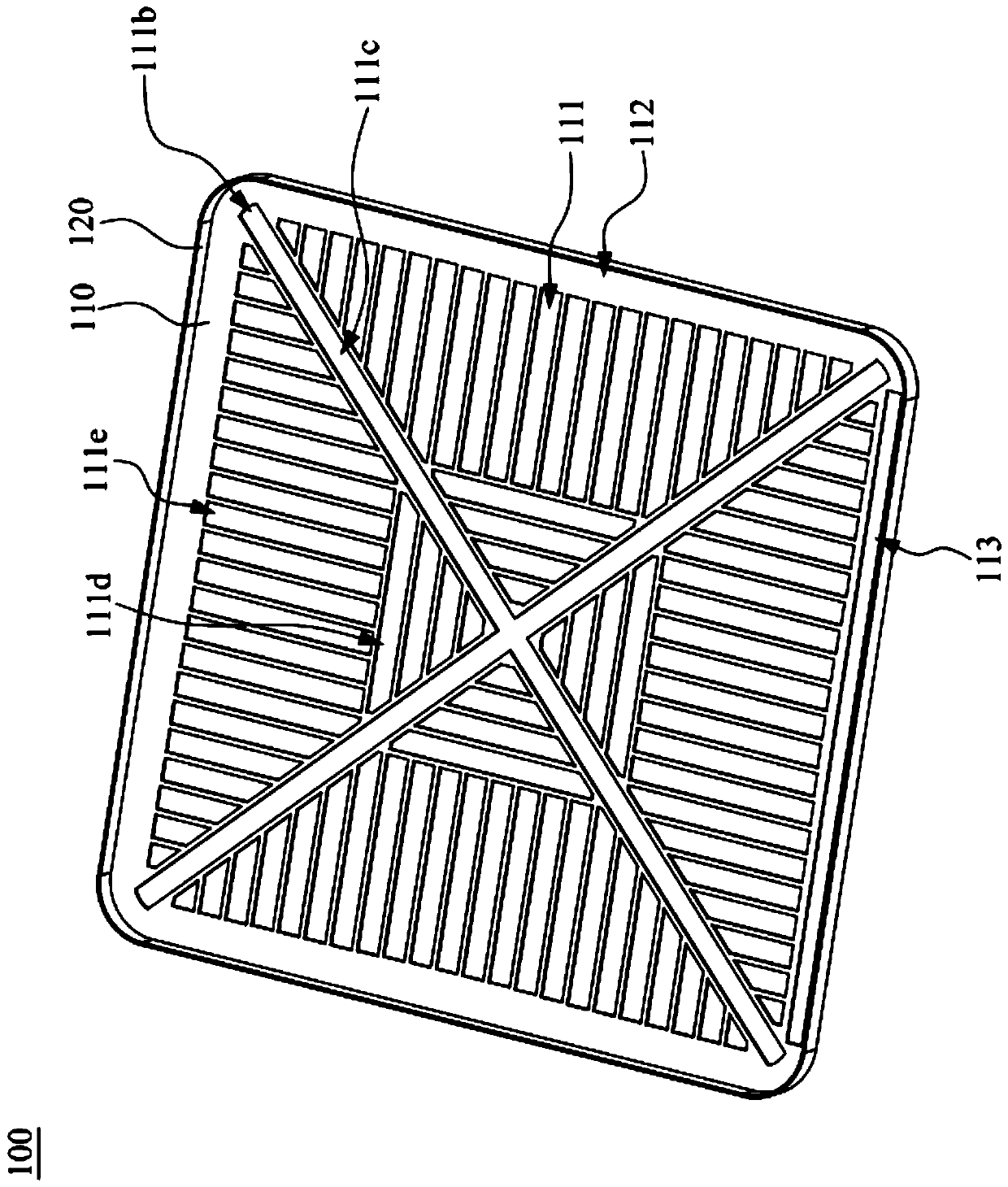

[0043] Please refer to figure 1 , which is a perspective view illustrating a patterning device 100 according to an embodiment of the present disclosure. The patterning device 100 is applied to bonding of display devices, and it can be used for substrates to be bonded (such as cover glass, not shown in figure 1 Middle) to form a specific liquid optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com