Plastic uptake mold structure for quick demolding and demolding method

A blister mold and demolding technology, applied in the field of rapid demolding blister mold structure and demolding, can solve the problems of high manufacturing and maintenance costs, troublesome operation, low degree of automation and intelligence, etc. The effect of improving reliability, reducing product defect rate and scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

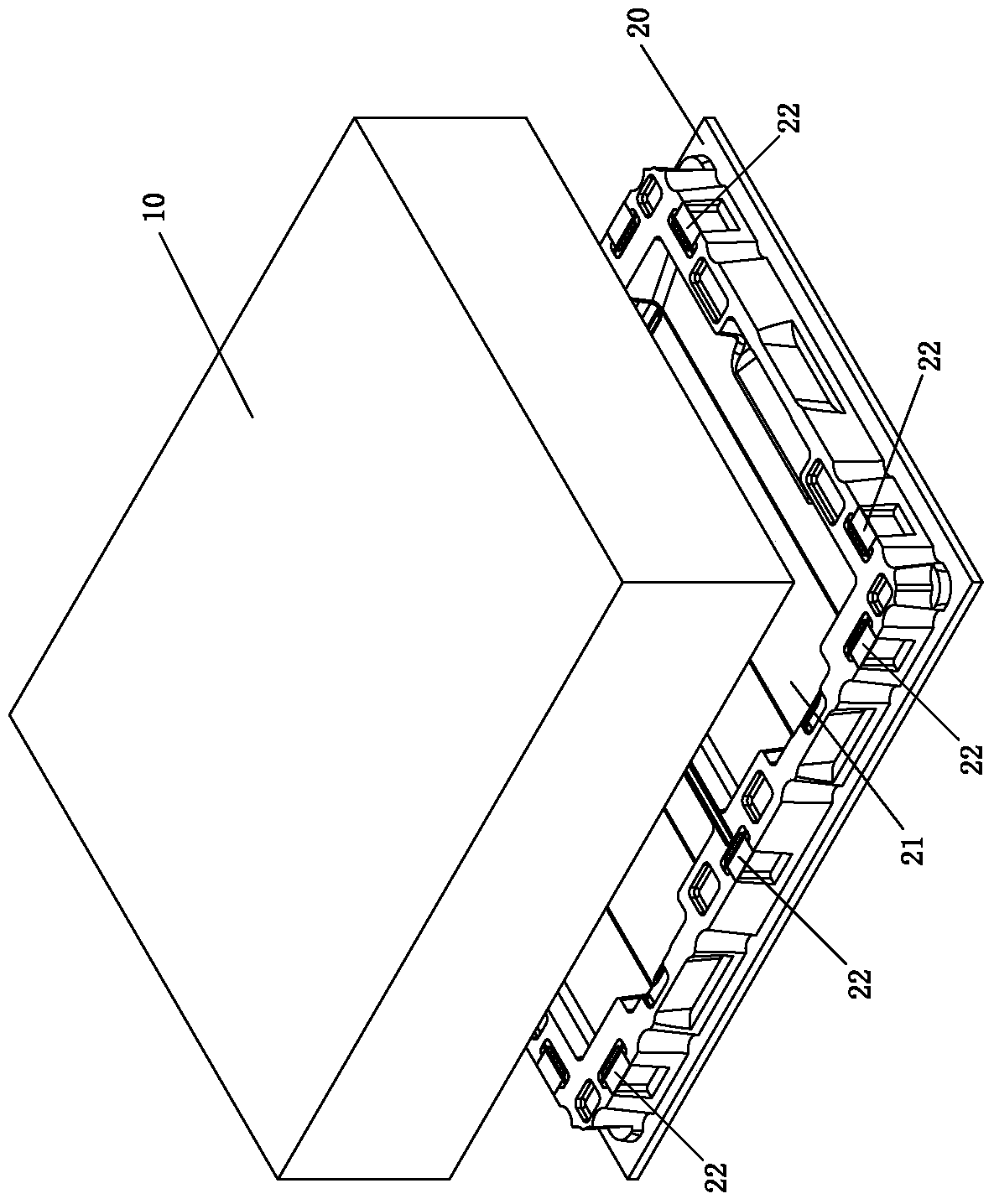

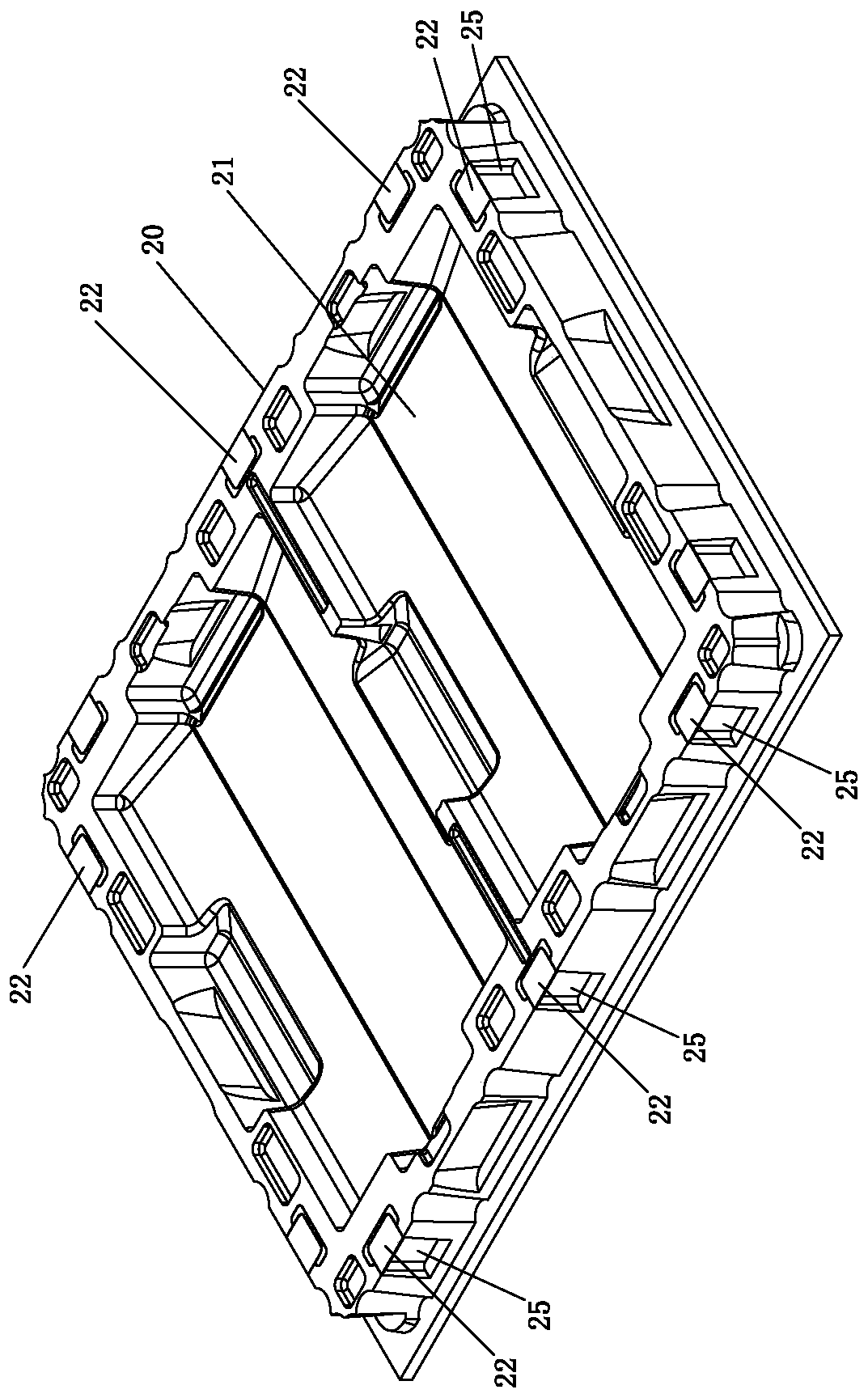

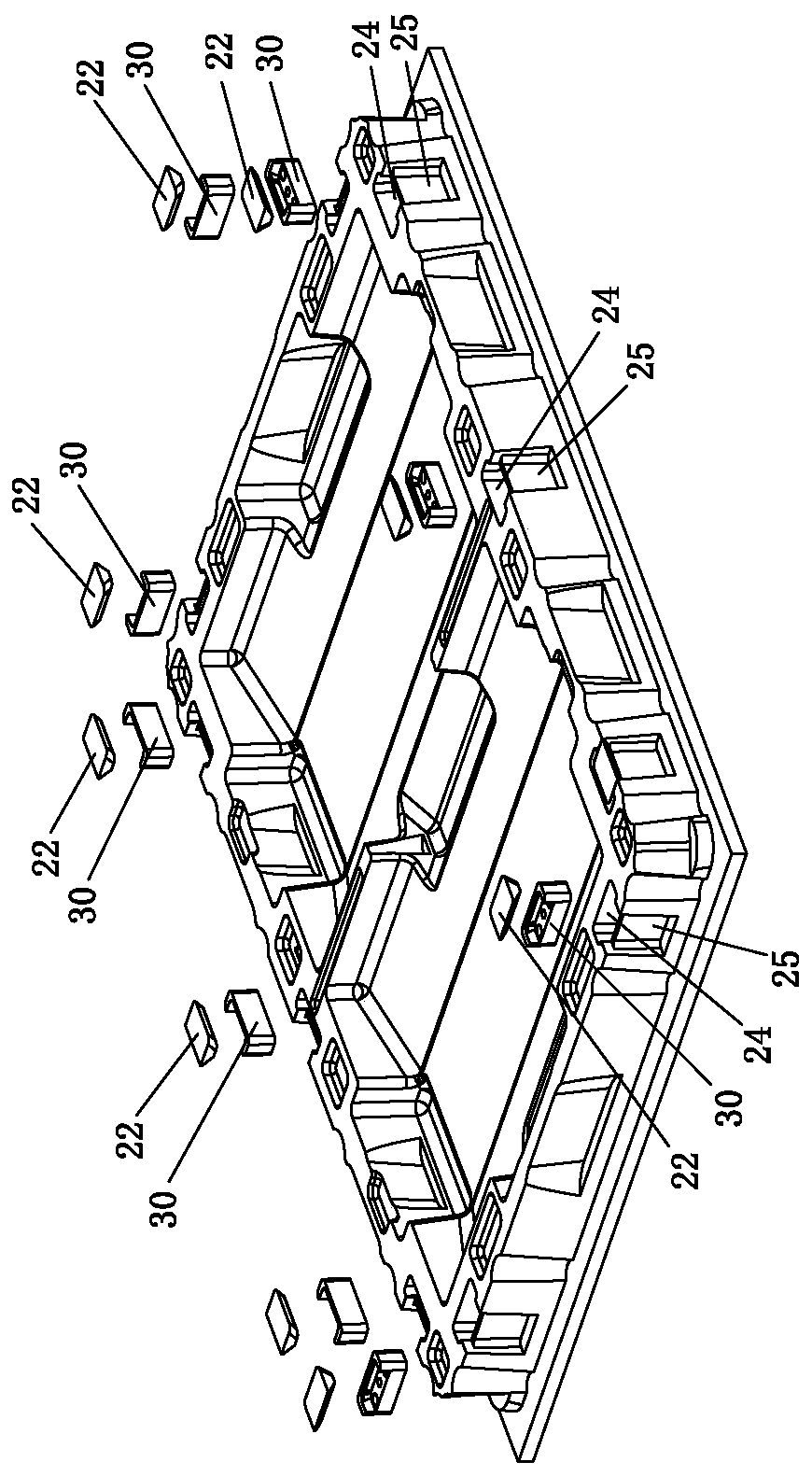

[0045] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the embodiment of the present invention.

[0046] A blister mold structure for rapid demoulding, including a mold body; wherein, the mold body has an upper mold 10 and a lower mold 20 correspondingly arranged up and down, and the top of the lower mold 20 is concavely provided with a cavity 21 , the lower mold 20 is provided with a number of movable buttons 22, and the movable buttons 22 are arranged along the outer peripheral edge of the cavity 21; preferably, there are 10 movable buttons 22, and the 10 movable buttons 22 are arranged The outer periphery of the cavity 21 is arranged in a spaced manner; here, 3, 2, 3, and 2 movable buckles 22 are respectively arranged around the cavity 21, forming a balanced and stable demoulding effect around the cavity 21 force;

[0047] The movable buckle 22 is installed on the lower mold 20 through a pivot shaft 23, and the movable buckle 22 can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com