Fixed safety belt suspension device for maintenance of substation power equipment

A suspension device and power equipment technology, applied in the direction of safety belts, life-saving equipment, etc., can solve the problems of difficult bolt fastening, different fixing structures, and inability to weld and fix, etc., to reduce types and models, facilitate use and operation, reduce The effect of physical exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

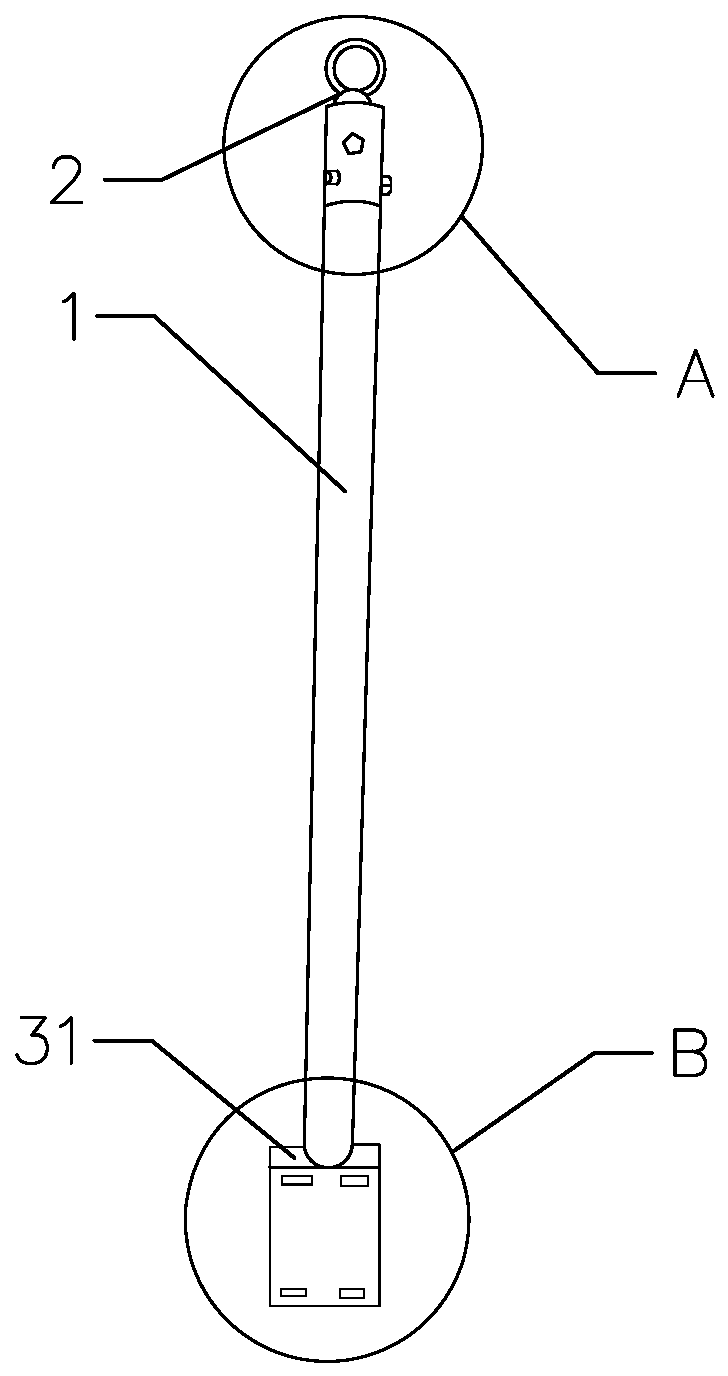

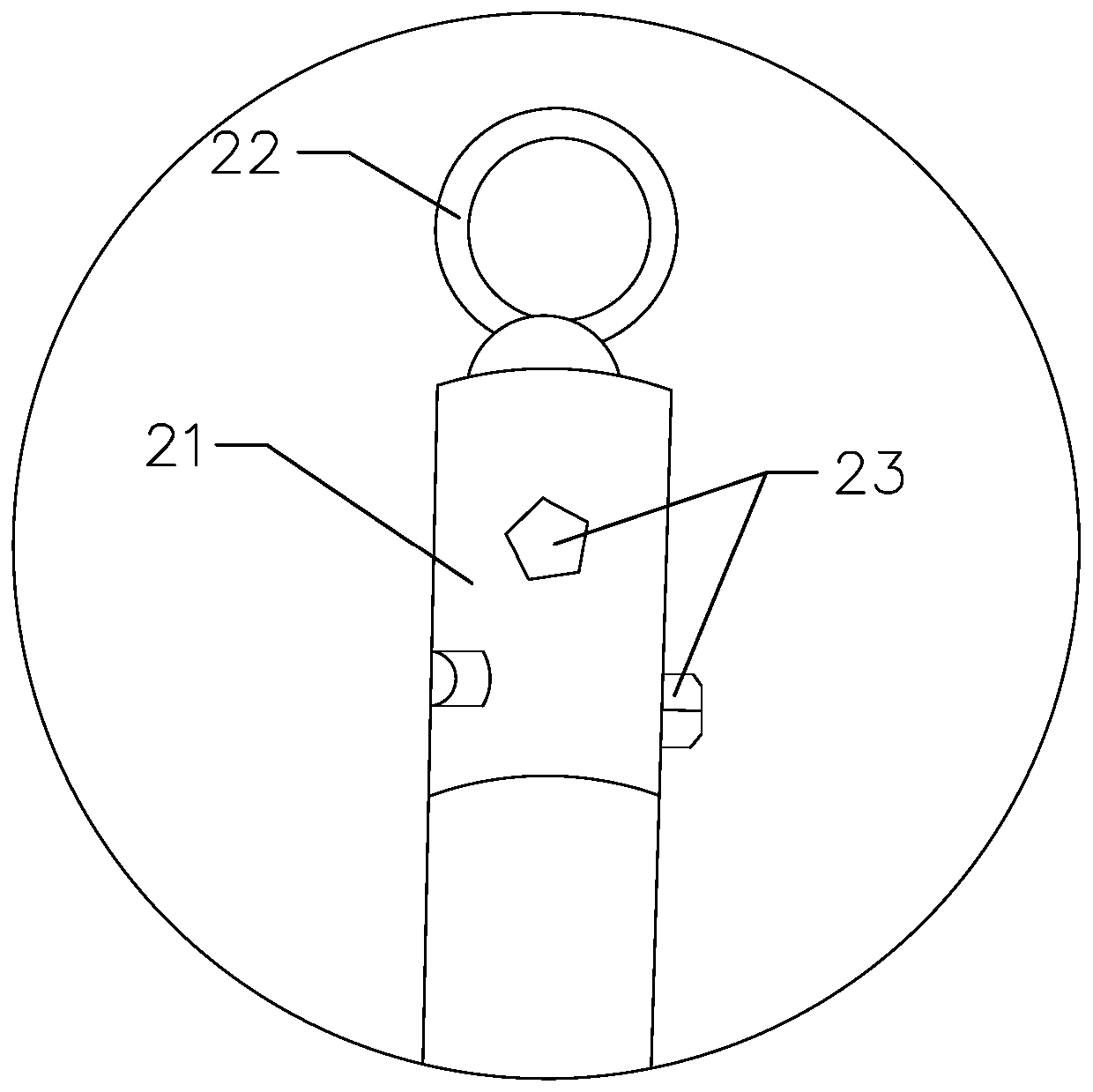

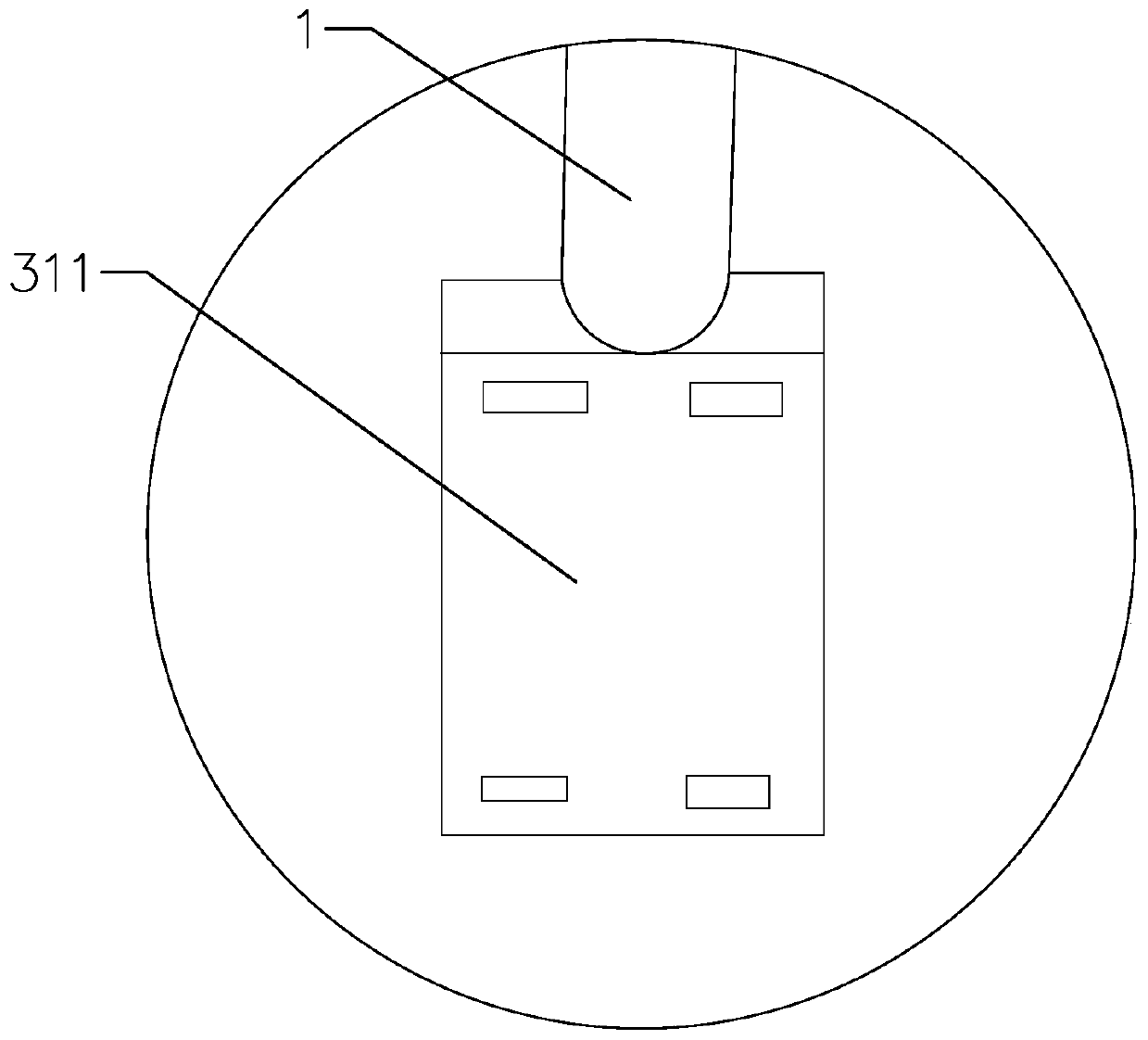

[0029] Such as Figures 1 to 4 As shown, the present invention provides a fixed safety belt suspension device for substation power equipment maintenance, including a standpipe 1, a safety belt hanging ring 2 and a fixing structure, and the safety belt hanging ring 2 and the fixing structure are respectively arranged on the standpipe 1 At both ends, the standpipe 1 is fixed together with the electrical equipment through a fixed structure, and a safety belt suspension device is provided to ensure the safety of the maintenance personnel when repairing the equipment.

[0030] In this embodiment, the fixed structure and the standpipe 1 are detachably fixed together, so that the fixed structure and the standpipe can be detachable, so that when maintaining different electrical equipment, different fixing structures can be selected to match with the standpipe, so as to achieve maintenance efficiency. Purpose, since the suspension device in the current maintenance is either fixed on th...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment lies in that the fixing structure is different.

[0037] In this example, if Figure 5 As shown, the fixing structure is a horizontal bar fixing structure, specifically an "L"-shaped horizontal bar fixing structure. Since there are various specifications of the existing middle horizontal bar, the "L"-shaped horizontal bar is one of them. This fixed structure is a fixed structure that can also be fixed to the crossbar on the utility pole when it is not convenient to fix it on the utility pole, so that the seat belt suspension device can be fixed, and the maintenance can also be well guaranteed Personal safety during maintenance and operation, and flexible and convenient operation.

[0038] Specifically, the "L"-shaped crossbar fixing structure includes an upper clamping plate 41, a lower clamping plate 42, and a connecting pipe 43 connecting the upper clamping plate 41 and the lower clamping plate 42. The ...

Embodiment 3

[0043] The difference between this embodiment and the second embodiment lies in that the fixing structure is different.

[0044] In this example, if Figure 6 As shown, the fixing structure is a cross bar fixing structure, specifically a channel steel type cross bar fixing structure. Since there are various specifications of the existing middle cross bar, the channel steel type cross bar is one of them. This fixed structure is a fixed structure that can also be fixed to the crossbar on the utility pole when it is not convenient to fix it on the utility pole, so that the seat belt suspension device can be fixed, and the maintenance can also be well guaranteed Personal safety during maintenance and operation, and flexible and convenient operation.

[0045] Concretely, the channel steel type cross bar fixing structure includes two parallel upper splints 51, a lower splint 52 and a vertical side plate 53. The upper splint 51 is provided with a connecting sleeve 54 sleeved on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com