Special automatic transmission brake belt piston clearance measuring and correcting method

A technology of automatic transmission and piston clearance, which is applied to components with teeth, transmission control, instruments, etc., can solve the problems of shifting delay, inability to mass-produce and use, unstable clearance, etc. effect of slices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

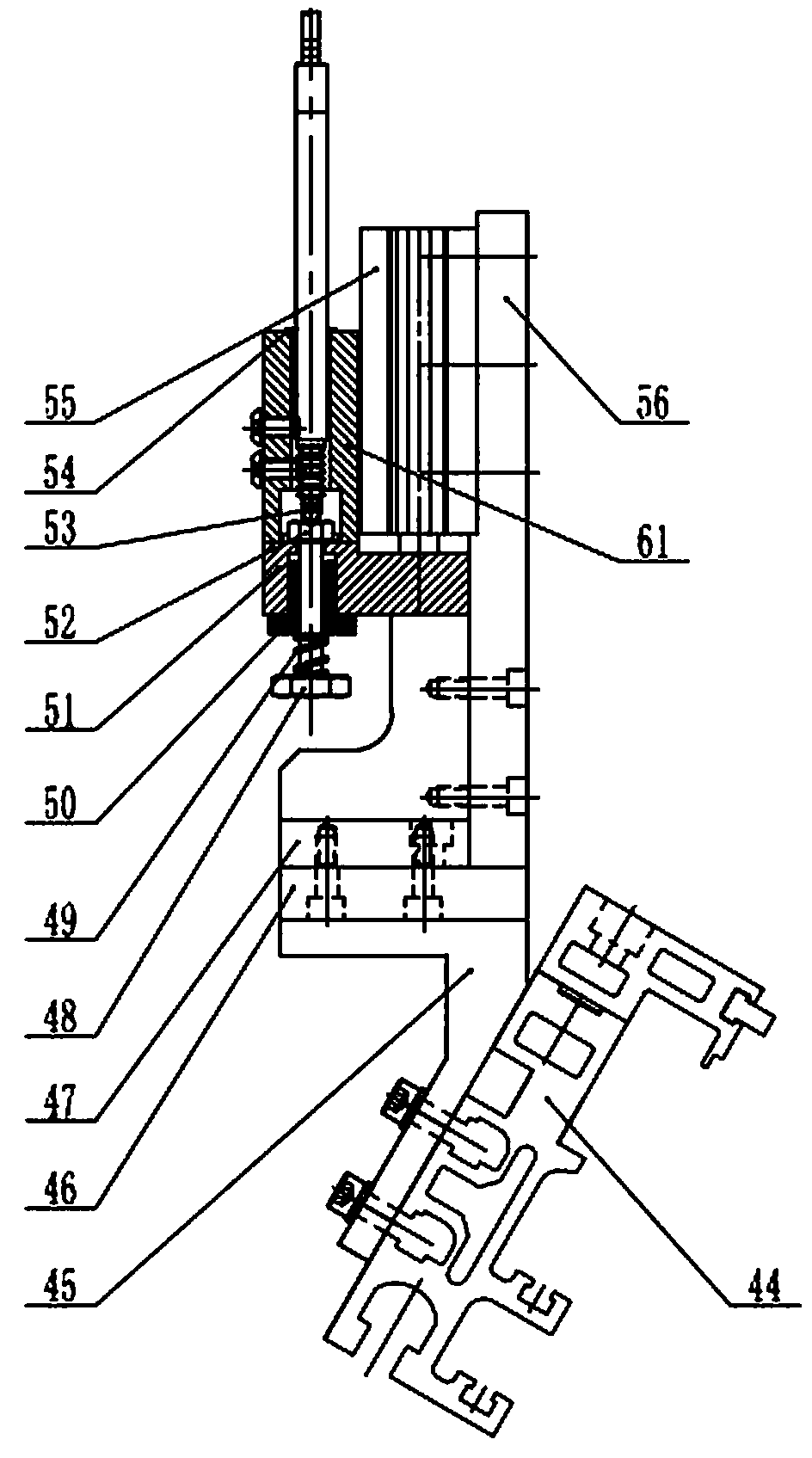

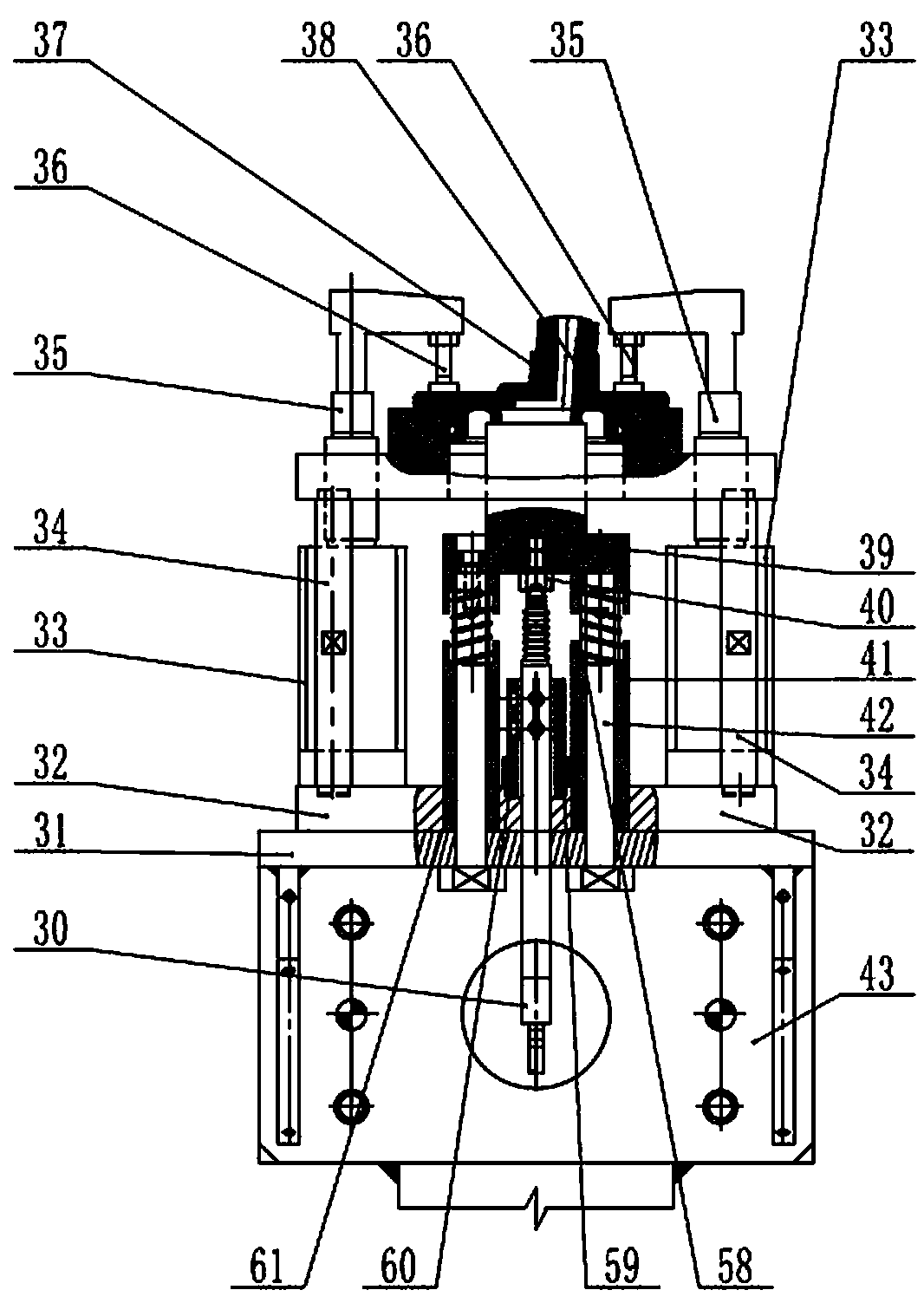

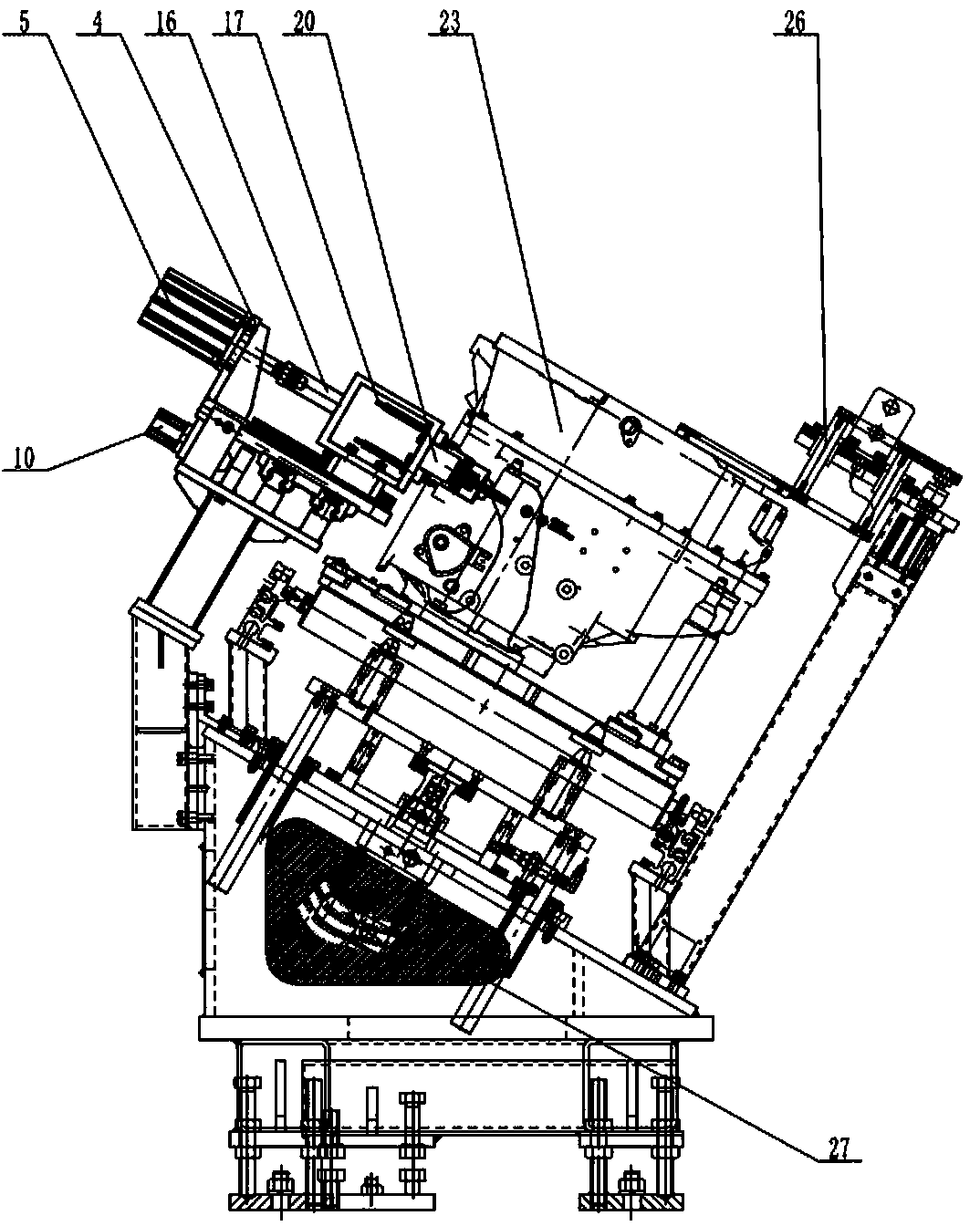

[0052] The reciprocating measuring mechanism includes a reciprocating measuring instrument moving unit fixing seat 11 as a mounting seat of the measuring mechanism parts, and the left and right sides of the reciprocating measuring instrument moving unit fixing seat 11 are respectively provided with a limit block fixing seat 6;

[0053] Two parallel linear guide rail fixing seats 8 are arranged in the middle of the moving unit fixing seat 11 of the reciprocating measuring instrument, and a horizontal linear guide rail 12 is arranged on the linear guide rail fixing seat 8, and a horizontal linear guide rail slider 15 is arranged above the horizontal linear guide rail 12 , the horizontal moving platform 3 is installed on the linear guide rail slider 15;

[0054] The left side of the lateral movement platform 3 is equipped with a sliding handle 1, and the sliding handle 1 is provided with a locking device button 2; the upper part of the lateral movement platform 3 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com