Blocking and sopping mechanism and drawing-pulling type water outlet device

A snap ring and snap sleeve technology, applied in the field of kitchen and bathroom, can solve the problems of complicated assembly, long life of the overall solution, inconvenient operation, etc., and achieve the effect of easy identification, good experience, and easy listing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

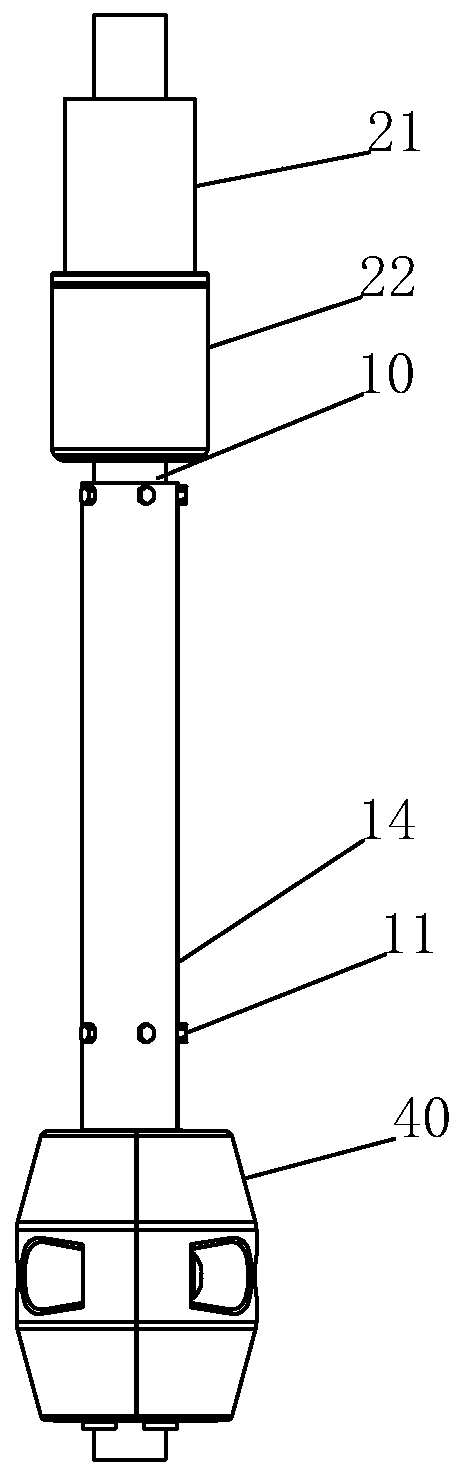

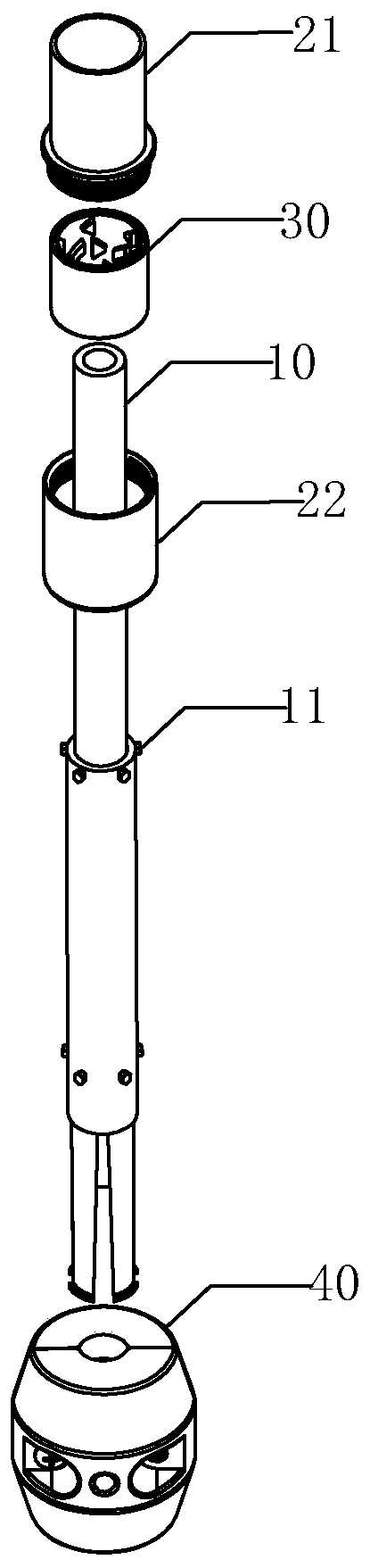

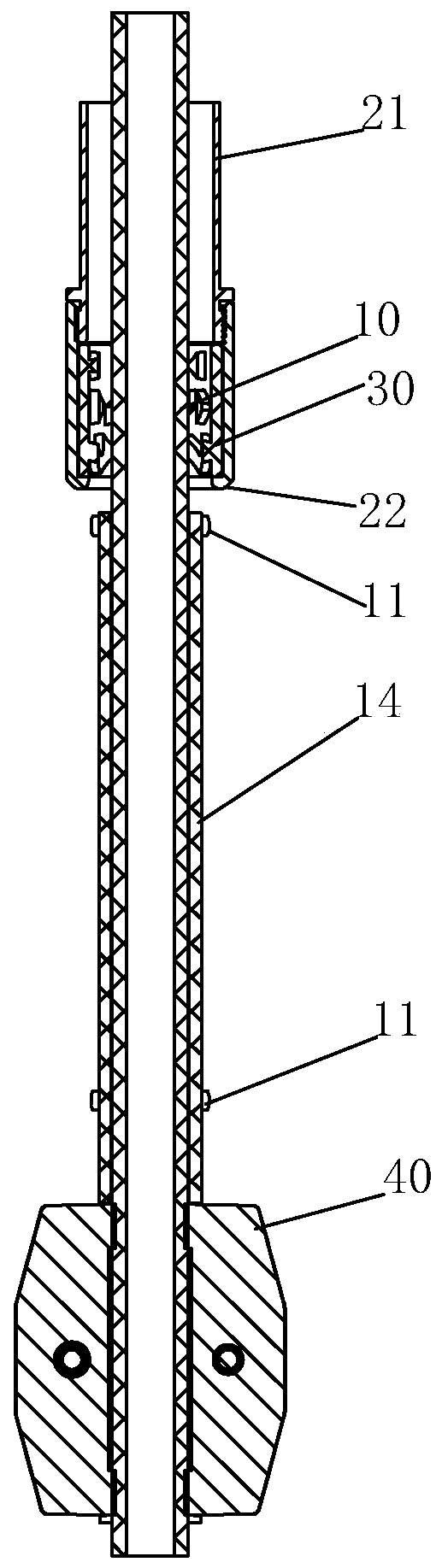

[0047] refer to Figure 1 to Figure 3 , a locking mechanism, including a tube body group, a fixed sleeve 20 and a snap ring 30, the tube body group is provided with a tube body 10 and a return member 40, etc., the tube body 10 can be a flexible pipe or a hard tube, and the fixed sleeve 20 Adopt one-piece structure. At least one bump group is provided on the tube body 10, and each bump group is provided with a plurality of bumps 11, and the plurality of bumps 11 are distributed circumferentially. The protruding point 11 can be a protruding block or a partially embedded movable steel ball. If it is a protruding block, it can be in the shape of a rhombus, an ellipse, a circle, etc., such as a rhombus. The upper slope 12, the bottom is provided with the lower slope 13 extending upwards along both sides respectively. The number of the bump groups can be one group, two groups, three groups or even more, and the number of bump groups represents the number of stops that can be achie...

Embodiment 2

[0073] refer to Figure 9 to Figure 11 , a locking mechanism, the pipe body 10 only needs to be locked when the longest drawing length is required, and only a group of uniformly distributed bumps 11 are required on the pipe body 10, and at the same time, the fourth convex Block 37 is taken and removed, and the positioning of the longest drawing length of the limit pipe body 10 can be realized. details as follows:

[0074] It includes a tube body set, a fixing sleeve 20 and a snap ring 30. The tube body set is provided with a tube body 10 and a return piece 40, etc., and the tube body 10 can be a hose or a hard tube. In this embodiment, only one bump group is provided on the tube body 10 (that is, the number of locking stages that can be realized is 1), and the bump group is provided with a plurality of bumps 11, and the plurality of bumps 11 are circumferentially distributed. The protruding point 11 can be a protruding block or a partially embedded movable steel ball. If it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com