Hydraulic support frame

A technology of hydraulic support and support controller, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., which can solve the problems of affecting the stability of support support, not being well adapted, and the forward tilt of the top beam, so as to increase the Coal control effect, adaptation to the roof environment, and the effect of avoiding the forward tilt of the support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

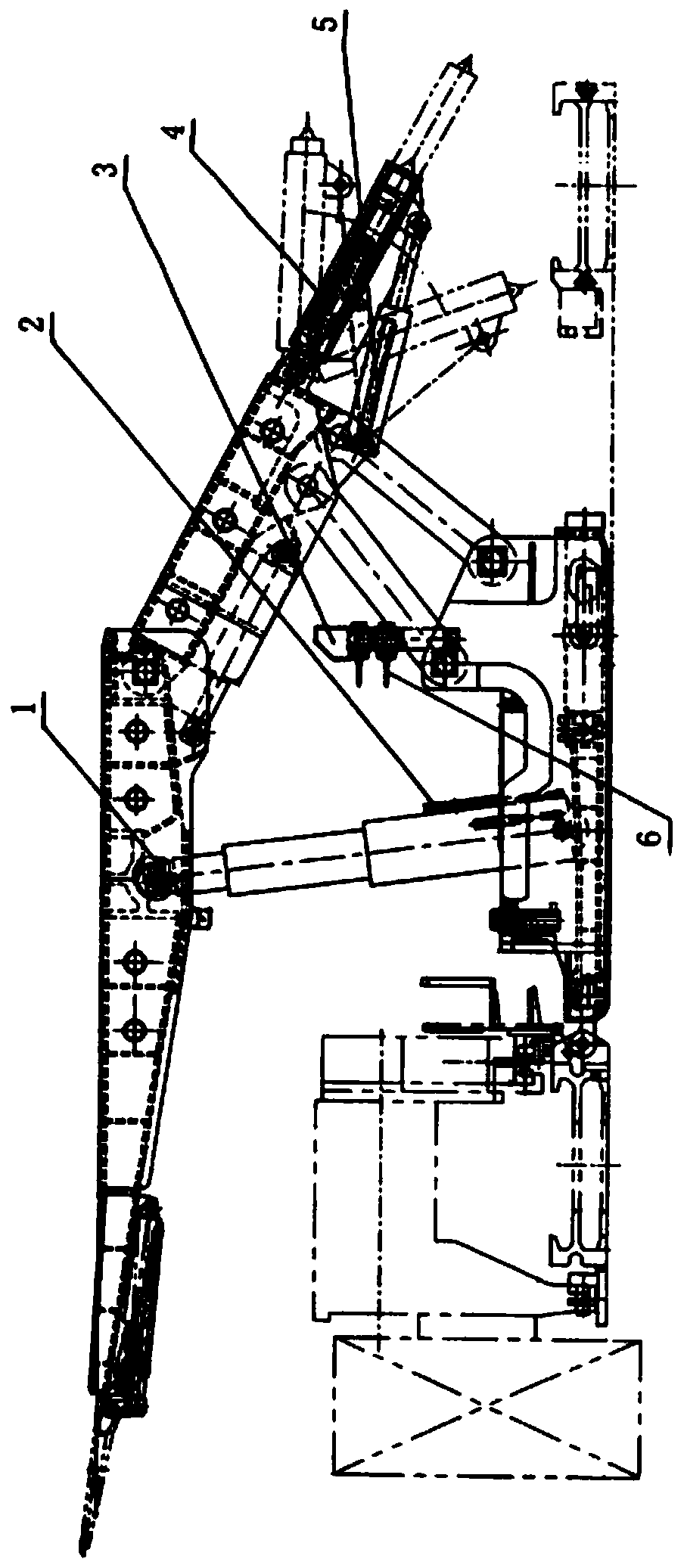

[0034] Example 1: In figure 1 , 2 It shows that the bracket of the present invention is composed of a bracket body and an electro-hydraulic control system.

[0035] The support body is a two-column cover-type low-level coal caving hydraulic support, which consists of a top beam, a column, a base, a cover beam, a balance jack, a front connecting stalk, a rear connecting stalk, side guards and side guard jacks, side guards and side guards. Guard plate pushing jack, front conveyor pushing jack, rear conveyor pulling jack, base lifting jack, and tail beam of coal discharge mechanism, tail beam jack, inserting plate and inserting plate jack, etc.

[0036] A tilt sensor 1 is installed on the top beam of the bracket and in front of the column, a pressure sensor 2 is installed on the valve plate of the hydraulic cylinder lower chamber of the column, an electro-hydraulic valve group 6 is installed on the operating frame of the base, and the bracket controller 3 is installed on the Ab...

Embodiment 2

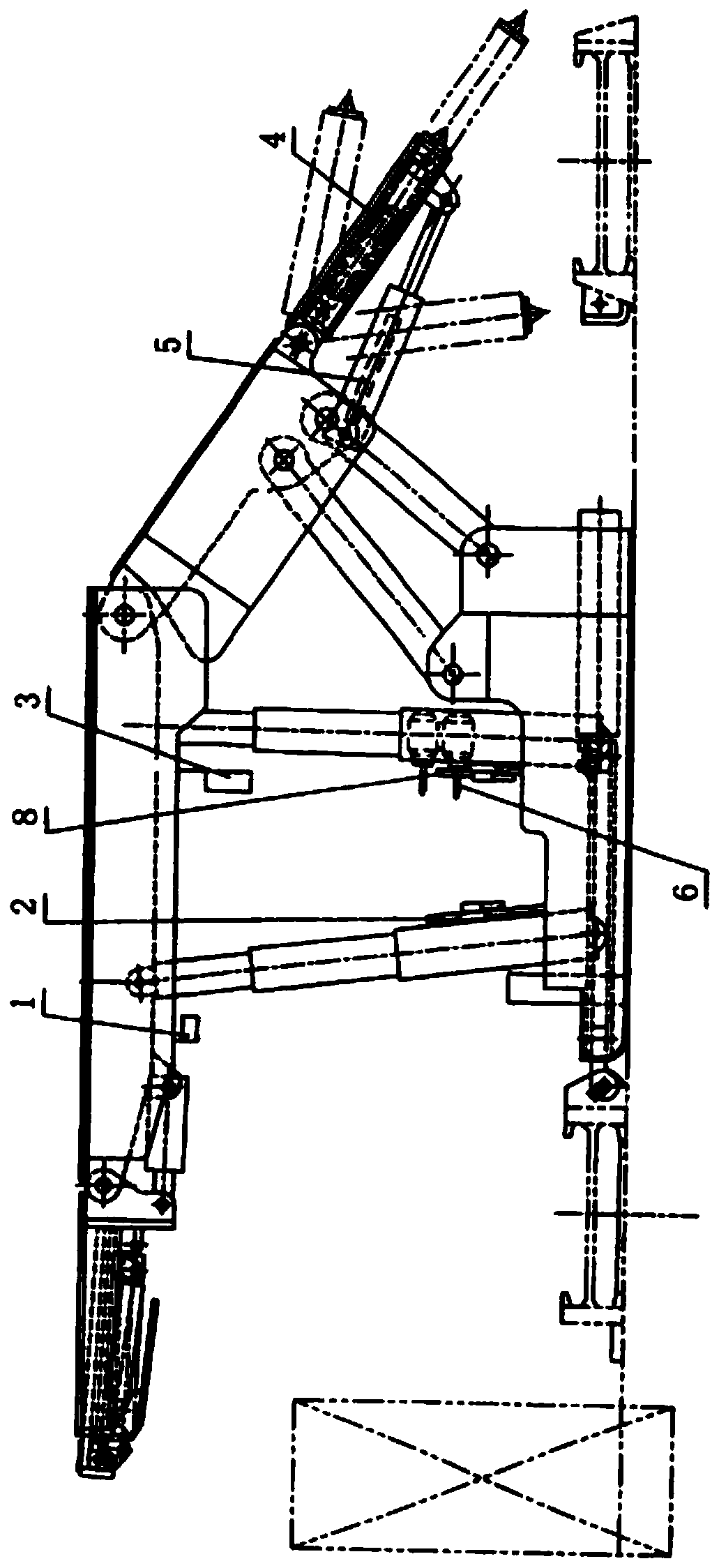

[0051] Example 2: image 3 Another form of the hydraulic support of the present invention is shown: an electro-hydraulic control four-column support shield type low-position top coal caving hydraulic support. Its upright column is four, divides front, rear two rows, does not need balance jack. The pressure sensor is divided into front and rear column pressure sensors 2 and 8, which are installed on the valve plate of the front and rear column lower chambers respectively. The expansion and contraction of the front and rear columns of the bracket are controlled by two main control valves of the 6th unit and two main control valves of the 4th unit of the electro-hydraulic valve group 6 respectively. The signal input end of the support controller 3 receives the signal of the roof beam inclination sensor 1, and the output socket F2 of the support controller 3 controls the expansion and contraction of the front and rear columns through the solenoid valve driver 10 and the electro-h...

Embodiment 3

[0054] Embodiment 3: The electro-hydraulic control top-coal caving method of the present invention includes the following five parts:

[0055] 1. Use electro-hydraulic control of the hydraulic support for caving coal, or install an electro-hydraulic control system on the hydraulic support for caving coal at low positions. The requirements of electro-hydraulic control caving hydraulic support and electro-hydraulic control system are as described in Example 1 and 2.

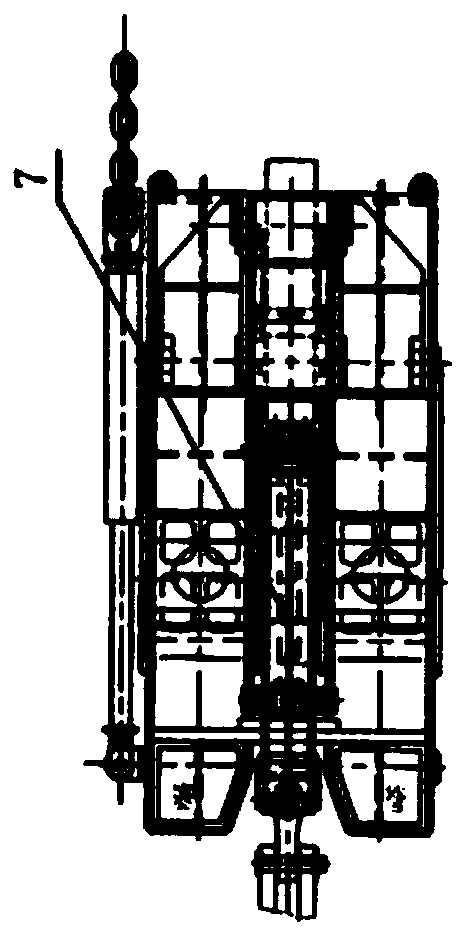

[0056] 2. Connect the bracket controllers 3 of all the brackets on the working face with trunk cables 20 in order or through the isolation coupler 15 to interconnect them into a network, and configure the necessary system accessories for connection at the same time, so that Figure 5 The unit system with the support controller 3 as the core in each support shown is combined into a complete set of full-face electro-hydraulic control system. exist Image 6 The pm31 full face electrohydraulic control system configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com