Beam-column joint for multiple high-rise wood/bamboo frame structures

A technology of frame structure and beam-column joints, which is applied in building structure, construction, etc., can solve problems such as restricting the development of high-rise wood/bamboo structure buildings, and achieve the effect of convenient and efficient construction and assembly, reducing construction procedures and avoiding additional pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

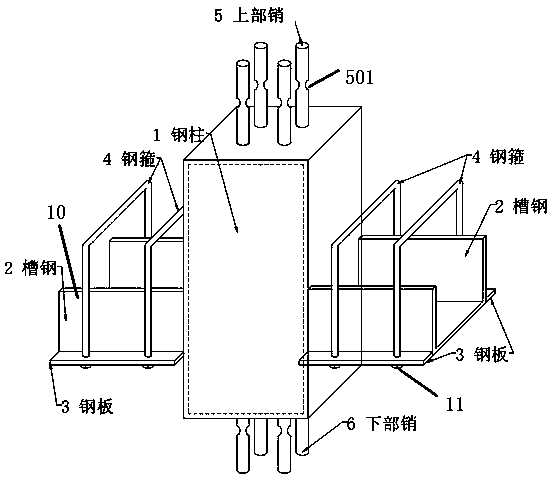

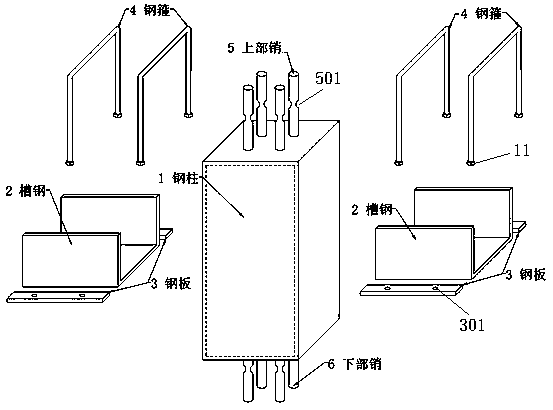

[0025] Below in conjunction with accompanying drawing, this patent is described further:

[0026] see figure 1 , figure 2 , image 3 The beam-column joint for a multi-story wood / bamboo frame structure shown includes a box-shaped steel column 1, which is vertically welded on the top surface of the steel column 1, and is used to cooperate with bolts 12 to connect the upper frame column 7 with the steel column 1, the upper pin 5 connected to the steel column 1 is vertically welded on the bottom surface of the steel column 1, and is used in conjunction with the bolt 12 to connect the lower frame column 8 with the steel column 1. The lower pin 6 is fixed on the side of the steel column 1, and is used to connect the A beam joint 10 semi-rigidly connected between the frame beam 9 and the steel column 1 .

[0027] The steel column 1 is a closed box structure, the top surface of the steel column 1 has the same shape and size as the cross section of the upper frame column 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com