Selenium-rich bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer and selenium-enriched technology, applied in fertilization devices, fertilizer mixtures, climate change adaptation, etc., can solve problems such as high production costs, adverse effects of actual use, and poor results, and achieve pollution-free and long-lasting selenium-enriched effects The effect of stabilizing and inhibiting the occurrence of crop diseases and insect pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

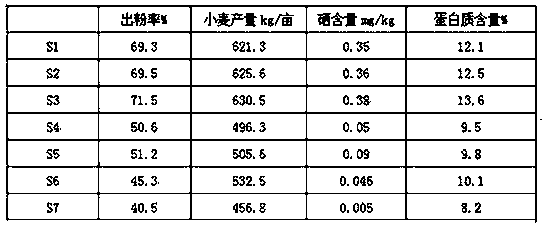

Examples

Embodiment 1

[0021] A selenium-enriched bio-organic fertilizer is prepared from the following raw materials in parts by weight: 200 parts of poultry manure, 100 parts of distiller's grain residue, 100 parts of furfural residue, 50 parts of diatomaceous earth, 4 parts of compound microbial agent, soil 6 parts of conditioner, 0.3 part of sodium selenite, 1 part of polylactic acid / glycolic acid nanospheres and 1 part of synergist;

[0022] The polylactic acid / glycolic acid nanospheres are prepared by the following method: take 25 mg of polylactic acid / glycolic acid and dissolve them in dichloromethane, add 100 μL of liquid perfluorohexane under ice-bath conditions, sonicate for 5 minutes, and then add the mixture Polyvinyl alcohol with a mass of 3% was homogenized by a dispersing homogenizer for 5 minutes to obtain double emulsion; the double emulsion was fully stirred to volatilize methylene chloride, washed with distilled water, and centrifuged to obtain polylactic acid / glycolic acid nanosph...

Embodiment 2

[0033] A selenium-enriched bio-organic fertilizer is prepared from the following raw materials in parts by weight: 300 parts of poultry manure, 150 parts of distiller's grain residue, 150 parts of furfural residue, 60 parts of diatomite, 5 parts of compound microbial agent, soil 8 parts of conditioning agent, 0.4 parts of sodium selenite, 3 parts of polylactic acid / glycolic acid nanospheres and 2 parts of synergist;

[0034] The polylactic acid / glycolic acid nanospheres are prepared by the following method: take 25 mg of polylactic acid / glycolic acid and dissolve them in dichloromethane, add 100 μL of liquid perfluorohexane under ice-bath conditions, sonicate for 5 minutes, and then add the mixture Polyvinyl alcohol with a mass of 3% was homogenized by a dispersing homogenizer for 5 minutes to obtain double emulsion; the double emulsion was fully stirred to volatilize methylene chloride, washed with distilled water, and centrifuged to obtain polylactic acid / glycolic acid nanosp...

Embodiment 3

[0045] A selenium-enriched bio-organic fertilizer is prepared from the following raw materials in parts by weight: 400 parts of poultry manure, 200 parts of distiller's grain residue, 200 parts of furfural residue, 70 parts of diatomaceous earth, 6 parts of compound microbial agent, soil 10 parts of conditioner, 0.5 parts of sodium selenite, 5 parts of polylactic acid / glycolic acid nanospheres and 3 parts of synergist;

[0046] The polylactic acid / glycolic acid nanospheres are prepared by the following method: take 25 mg of polylactic acid / glycolic acid and dissolve them in dichloromethane, add 100 μL of liquid perfluorohexane under ice-bath conditions, sonicate for 5 minutes, and then add the mixture Polyvinyl alcohol with a mass of 3% was homogenized by a dispersing homogenizer for 5 minutes to obtain double emulsion; the double emulsion was fully stirred to volatilize methylene chloride, washed with distilled water, and centrifuged to obtain polylactic acid / glycolic acid nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com