A kind of magnesium oxide retarder based on multivitamin, composite magnesium oxide and application

A technology of complex vitamins and magnesium oxide, which is applied in the field of cement-based material admixtures, can solve the problems of magnesium oxide hydration ineffectiveness, and achieve the effects of reducing the hydration rate, slowing down the hydration rate, and reducing the formation of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] 2.1 Preparation method of retarder

[0028] vitamin C, vitamin B 1 , Vitamin B 2 and vitamin B 6 Crush and grind into powder, weigh the powder according to the proportion, and mix evenly to obtain the required magnesium oxide retarder.

Embodiment 1

[0029] Example 1: According to the method in part 2.1, the vitamin tablets are crushed and ground into powder, and in parts by weight, 40 parts of vitamin C and 20 parts of vitamin B 1 , 20 servings of vitamin B 2 , 20 servings of vitamin B 6 , mixed evenly to obtain retarder.

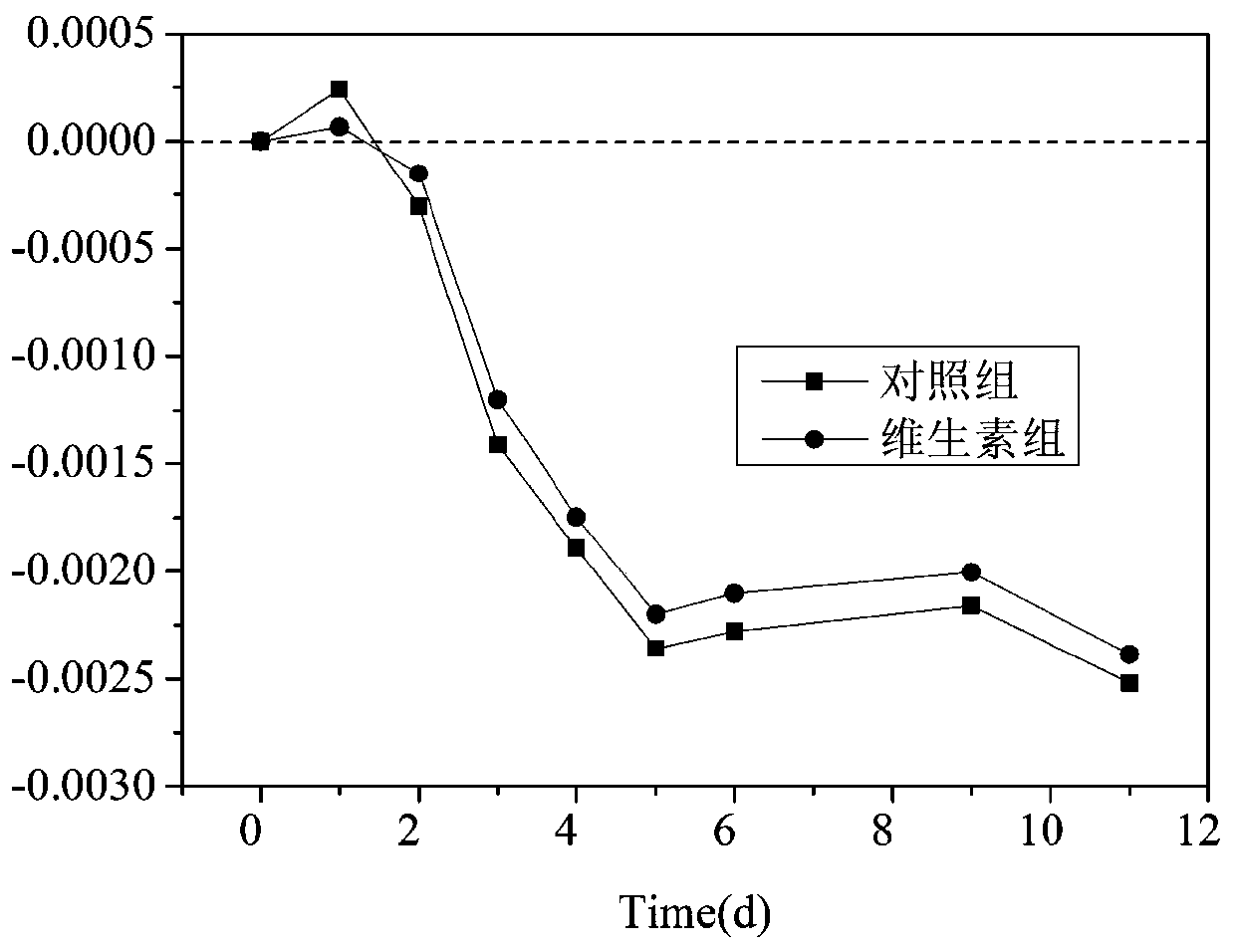

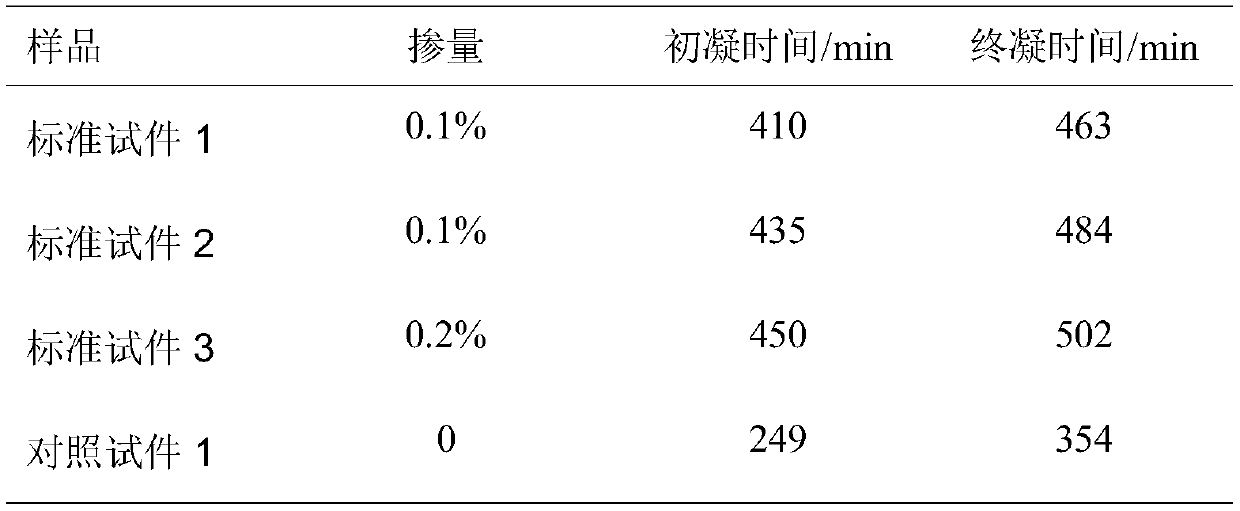

[0030] Take 0.1% magnesia mass retarder and dissolve it in water, add magnesia and mix to make standard test piece 1, measure the setting time, and record it in Table 1.

Embodiment 2

[0031] Example 2: According to the method in part 2.1, the vitamin tablets are crushed and ground into powder, and by weight, 55 parts of vitamin C and 15 parts of vitamin B 1 , 15 servings of vitamin B 2 , 15 servings of vitamin B 6 , mixed evenly to obtain retarder.

[0032] Take 0.1% magnesia mass retarder and dissolve it in water, add magnesia and mix to make standard test piece 2, measure the setting time, and record it in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com