Automatic unwinding and winding device and automatic unwinding and winding method

An automatic unloading and film roll technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of heavy load, low degree of automation, and high labor intensity of workers, so as to simplify the structure and reduce equipment required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

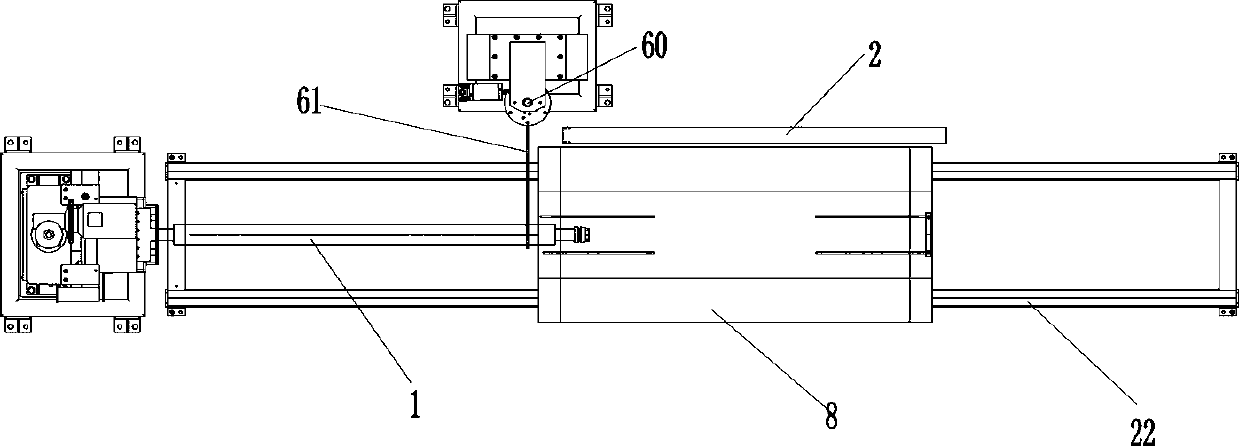

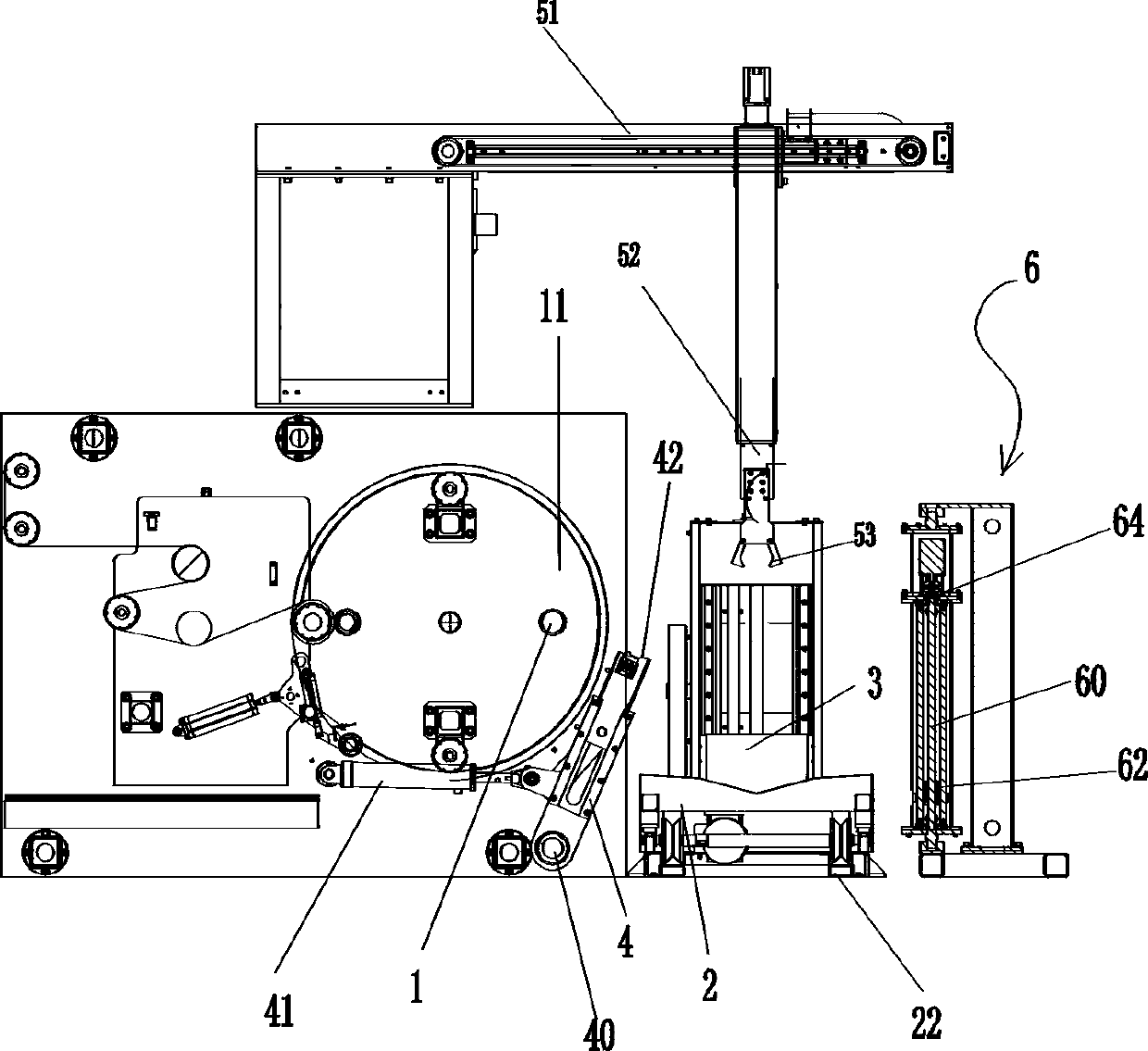

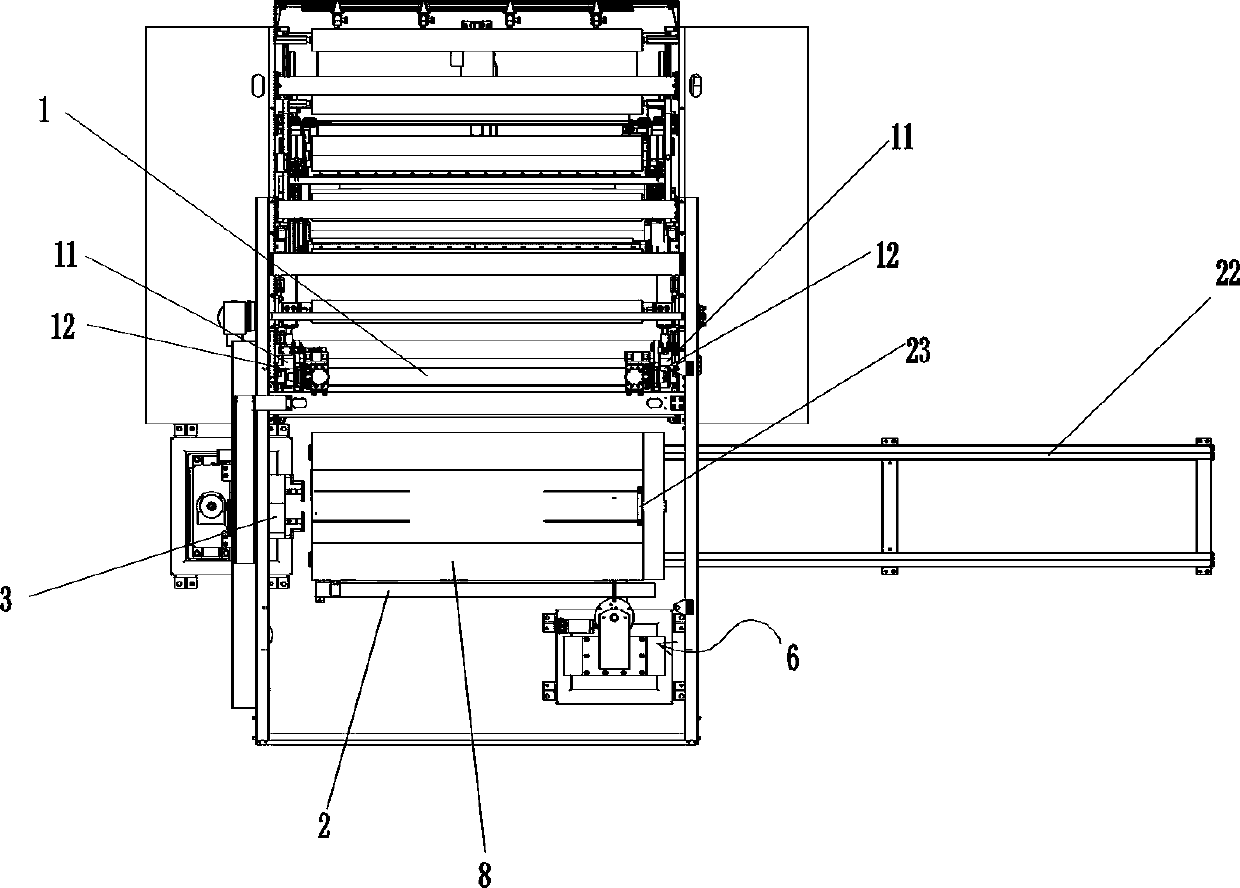

[0077] An automatic unwinding core device, comprising two left and right winding shaft supports 11, an inflatable winding shaft 1 is arranged between the left and right two winding shaft supports 11, and the left and right ends of the winding shaft 1 are installed on the left and right sides respectively. On the first rewinding shaft support 11, the central axis of the rewinding shaft 1 extends laterally. Overlapping with the central axis of the winding shaft 1, the inner cavity 120 of the shaft sleeve has a taper corresponding to the end of the winding shaft; the shaft sleeve 12 is axially movably installed on the corresponding side of the winding shaft support 11, and each winding shaft The support 11 is also provided with a first cylinder that drives the shaft sleeve 12 on the corresponding side to move laterally, and each shaft sleeve 12 forms a movable plug-in relationship with the end of the winding shaft on the corresponding side, as figure 1 , figure 2 , image 3 , ...

Embodiment 2

[0086] A method for automatically unloading cores, which is characterized in that the automatic unloading cores device of Embodiment 1 is adopted, and includes the following steps in sequence:

[0087] (1) When the film roll 8 reaches the set length and is ready to be unloaded, the film roll 8 is wound outside the paper core tube, and the paper core tube is set outside the inflatable reel shaft 1, and the reel shaft 1 is in the expansion state. Tight state and closely combined with the paper core tube, the left and right ends of the winding shaft 1 are respectively inserted in the bushings 12 on the corresponding sides, as Figure 4 Shown; Carrying trolley 2 is positioned at the rear bottom of take-up shaft 1, as figure 1 , figure 2 , image 3 As shown, the two unloading swing arms 4 are in a backward tilting state, as Figure 7 As shown, the support arm support 62 is at the lower end of its vertical movement track, and the length of the horizontal support arm 61 is in a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com