Fragrance-producing Laomian mantou and preparation method thereof

A technology for old noodles and steamed buns, which is applied in the field of producing fragrant old flour steamed buns and their production, can solve the problems of bland flavor, poor sensory quality and low aroma of steamed buns, and achieve the effects of good taste, stable properties and high content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

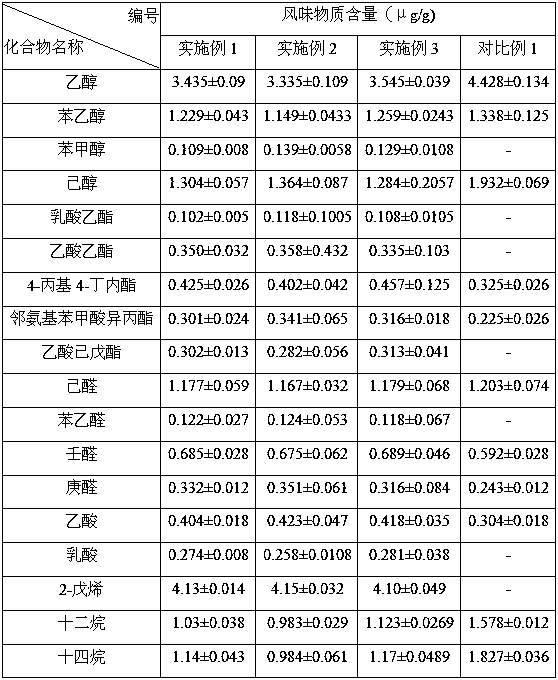

Examples

Embodiment 1

[0034] (1) Knead 0.5g of the aroma-producing yeast preparation activated in Reference Example 1, 0.5g of active dry yeast preparation, 0.2g of plantarum lactobacillus preparation, 45g of water and 100g of flour until evenly kneaded. Ferment for 6 hours until the pH of the dough is 4.3 to obtain 200 g of fermented sourdough;

[0035](2) Knead 80g of the fermented sourdough obtained in step (1) with 480g of water and 1000g of flour until evenly kneaded, and carry out secondary fermentation for 10 hours at a humidity of 80%RH and 30°C to obtain 2300g of secondary fermented dough, adding 62g of baking soda until the pH value of the even dough is 5.8, shaped and steamed to obtain fragrant old noodle steamed buns.

Embodiment 2

[0037] (1) Knead 20g of the aroma-producing yeast preparation activated in Reference Example 1, 20g of active dry yeast preparation, 5g of Lactobacillus plantarum preparation, 2.0kg of water and 5kg of flour until evenly kneaded, and carry out a fermentation at 30°C 8h until the pH value of the dough is 4.5, and 9.5kg of fermented sourdough is obtained;

[0038] (2) Knead 5kg of the fermented sourdough obtained in step (1) with 23kg of water and 50kg of flour until evenly kneaded, and carry out secondary fermentation for 12 hours at a humidity of 70%RH and 28°C to obtain 95kg of secondary fermented dough, adding 8.05kg of baking soda until the pH value of the even dough is 6.0, shaped and steamed to produce fragrant old noodle steamed buns.

Embodiment 3

[0040] (1) Knead 60g of the aroma-producing yeast preparation activated in Reference Example 1, 60g of active dry yeast preparation, 30g of plantarum lactobacillus preparation, 5kg of water and 10kg of flour until evenly kneaded, and ferment for 10 hours at 32°C To dough pH value is 4.0, obtains 18kg fermented sourdough;

[0041] (2) Knead 1.2kg of the fermented sourdough obtained in step (1) with 4.2kg of water and 10kg of flour until evenly kneaded, and carry out secondary fermentation for 8 hours at a humidity of 90%RH and 32°C to obtain 20kg of secondary fermented dough , add 1.85kg of baking soda until the pH value of the even dough is 7.0, shape it, steam it, and get fragrant old-fashioned steamed buns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com