Preservation technology of zongzi

A kind of zongzi and technology, applied in the field of zongzi preservation technology, can solve the problems of the appearance, taste and flavor of the zongzi being evenly affected, prolonging the shelf life of the zongzi, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

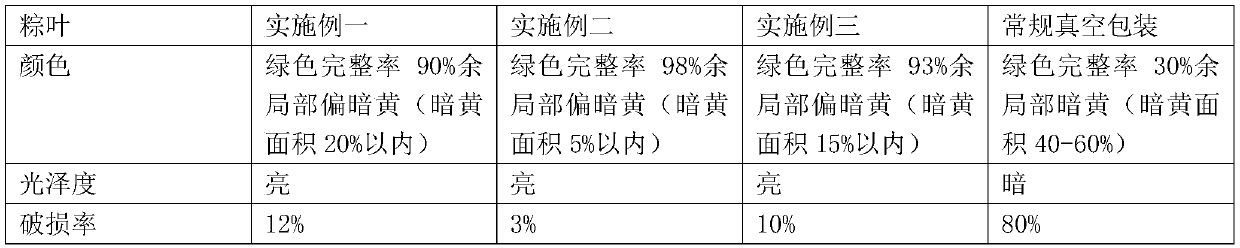

Embodiment 1

[0035] Zongzi preservation process, including:

[0036] A) steaming: steaming the steamed dumplings as raw material;

[0037] B) cooling: the steamed rice dumplings are cooled;

[0038] C) coating: coating the viscous fresh-keeping material on the surface of the zongzi after cooling,

[0039] Among them, the fresh-keeping material includes the following parts by weight of component A, component B, and component A: 5 parts of grape seed essential oil, 4 parts of fennel essential oil, 1 part of ascorbic acid, 5 parts of citric acid, 5 parts of glacial acetic acid, zein 30 parts of film, the slurry that A component is made of is coated on the surface of described zongzi to form film layer,

[0040] Component B: 18 parts of straw ash, 10 parts of water, 5 parts of glycerin, and 4 parts of konjac flour. The slurry composed of the B component is coated on the surface of the A component to form a protective layer with a bactericidal function;

[0041] D) packing: the zongzi coated...

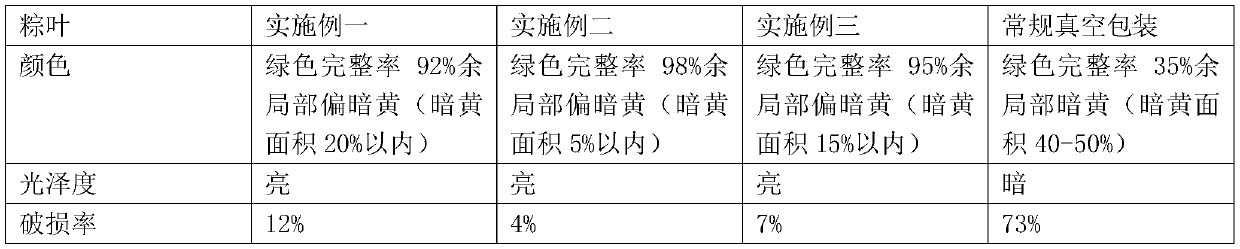

Embodiment 2

[0044] Zongzi preservation process, including:

[0045] A) steaming: steaming the steamed dumplings as raw material;

[0046] B) cooling: the steamed rice dumplings are cooled;

[0047] C) coating: coating the viscous fresh-keeping material on the surface of the zongzi after cooling,

[0048] Among them, the fresh-keeping material includes the following parts by weight of component A, component B, and component A: 8 parts of grape seed essential oil, 6 parts of fennel essential oil, 2 parts of ascorbic acid, 7 parts of citric acid, 7 parts of glacial acetic acid, zein 35 parts of film, the slurry that A component is made of is coated on the surface of described zongzi to form film layer,

[0049] Component B: 25 parts of straw ash, 15 parts of water, 10 parts of glycerin, and 6 parts of konjac flour. The slurry composed of the B component is coated on the surface of the A component to form a protective layer with a bactericidal function;

[0050] D) packing: the zongzi coat...

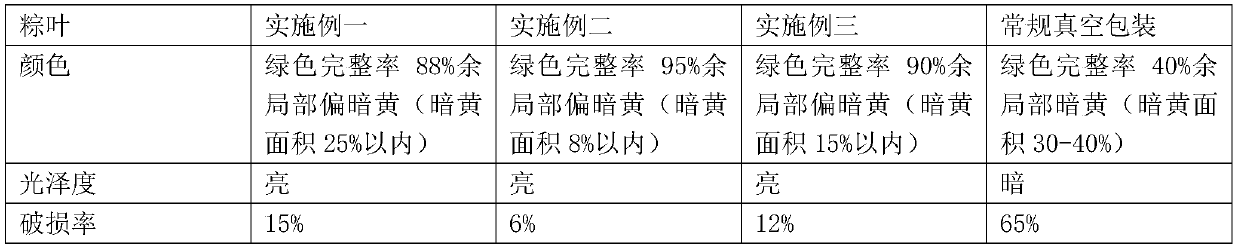

Embodiment 3

[0054] Zongzi preservation process, including:

[0055] A) steaming: steaming the steamed dumplings as raw material;

[0056] B) cooling: the steamed rice dumplings are cooled;

[0057]C) coating: coating the viscous fresh-keeping material on the surface of the zongzi after cooling,

[0058] Among them, the fresh-keeping material includes the following parts by weight of component A, component B, and component A: 6 parts of grape seed essential oil, 5 parts of fennel essential oil, 1.5 parts of ascorbic acid, 6 parts of citric acid, 6 parts of glacial acetic acid, zein 33 parts of film, the slurry that A component is made of is coated on the surface of described rice dumpling to form film layer,

[0059] Component B: 20 parts of straw ash, 12 parts of water, 8 parts of glycerin, and 5 parts of konjac flour. The slurry composed of the B component is coated on the surface of the A component to form a protective layer with a bactericidal function;

[0060] D) packing: the zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com