Peanut seed sowing self-disturbance seed discharge disc of suction seed discharge apparatus

An air-suction and seed-metering technology, which is applied to the parts of the planter, can solve the problems of missed seeding and damage, leakage of seed holes, and short filling time, and achieves the effects of reliable work, simple processing and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

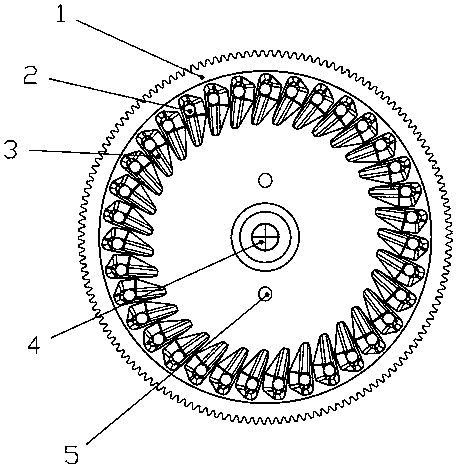

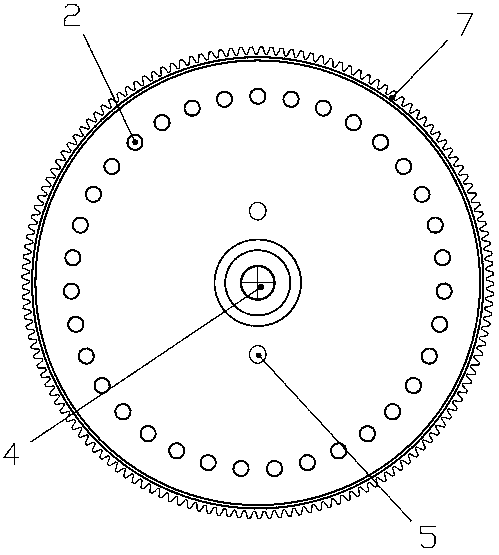

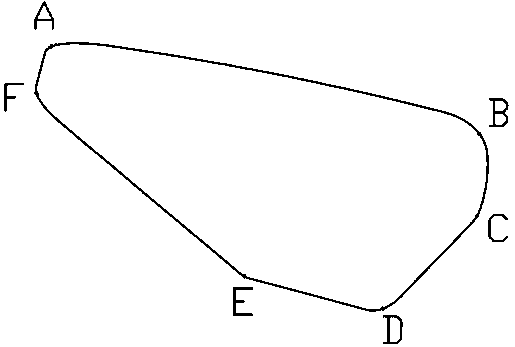

[0027] refer to figure 1 , figure 2 and Figure 4 , an air-suction seed metering device self-disturbance seeding disc for peanut sowing, comprising a disc body 1, a central mounting hole 4, a positioning guide hole 5, a seed filling groove 3, and a disc body 1 are provided on the disc body 1. On the front of the body, the disturbance stirring bar 6 formed by every two adjacent seed-filling grooves 3 areas; the center position of the disc body 1 protrudes outward, and a central mounting hole 4 is provided on it, and positioning guides symmetrically distributed are arranged on the periphery Holes 5; a plurality of three-dimensional seed-filling grooves 3 fitting the outer shape of peanuts are evenly distributed on the periphery of the disk body; the back of the disk body 1 is provided with a ventilation hole 2 communicating with the seed-filling groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com