Gas feed method for a gas engine or dual-fuel engine, and gas supply apparatus for same

A dual-fuel engine, gas engine technology, applied in combustion engines, internal combustion piston engines, oil supply devices, etc., can solve the problems of expensive, unoptimized supply of internal combustion engines, inaccurate gas dosing, etc., and achieve accurate gas dosing. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

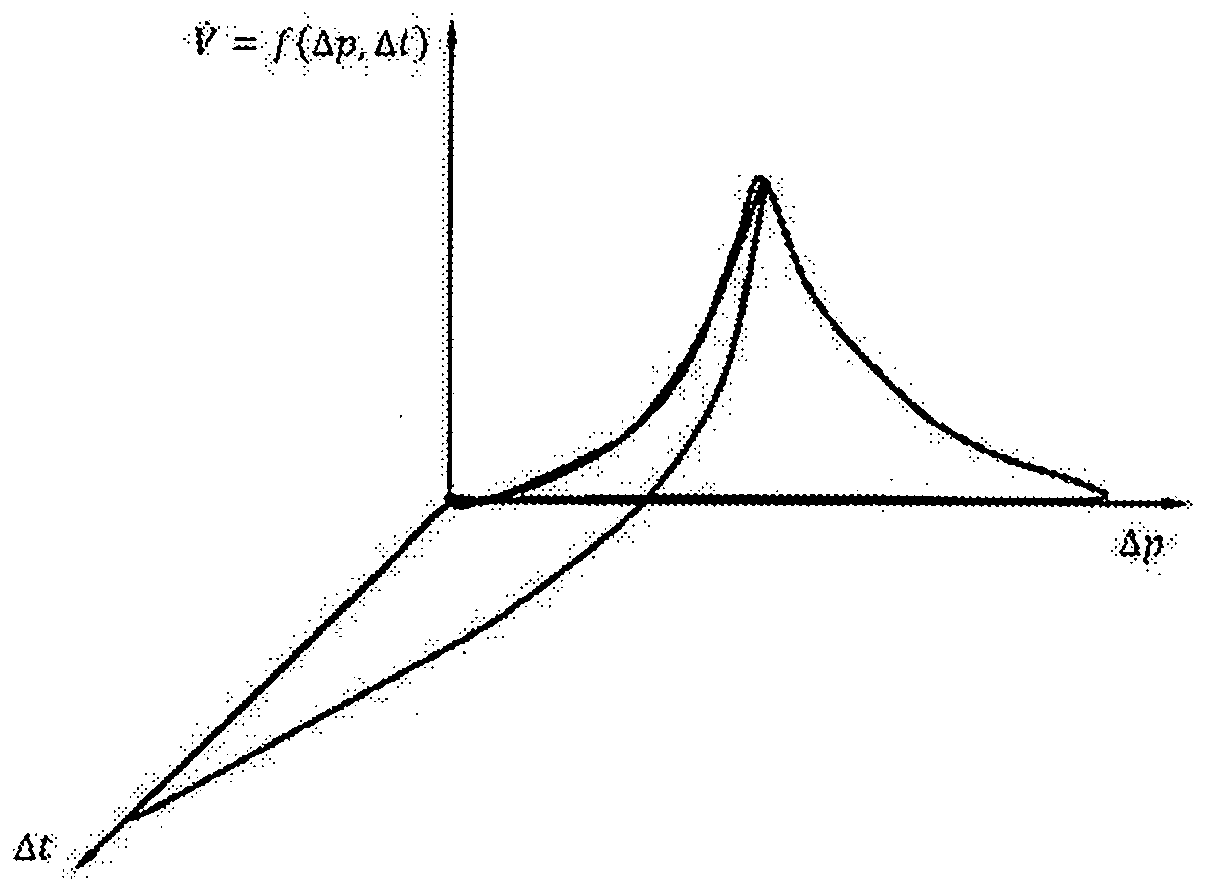

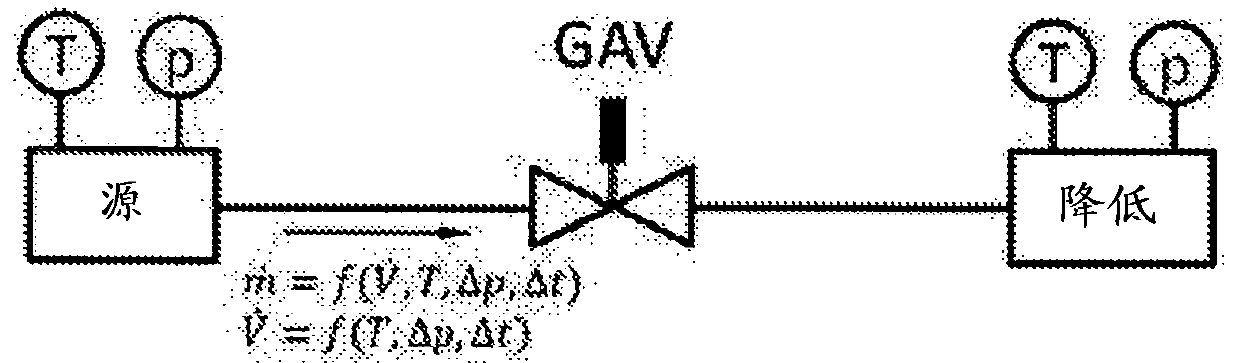

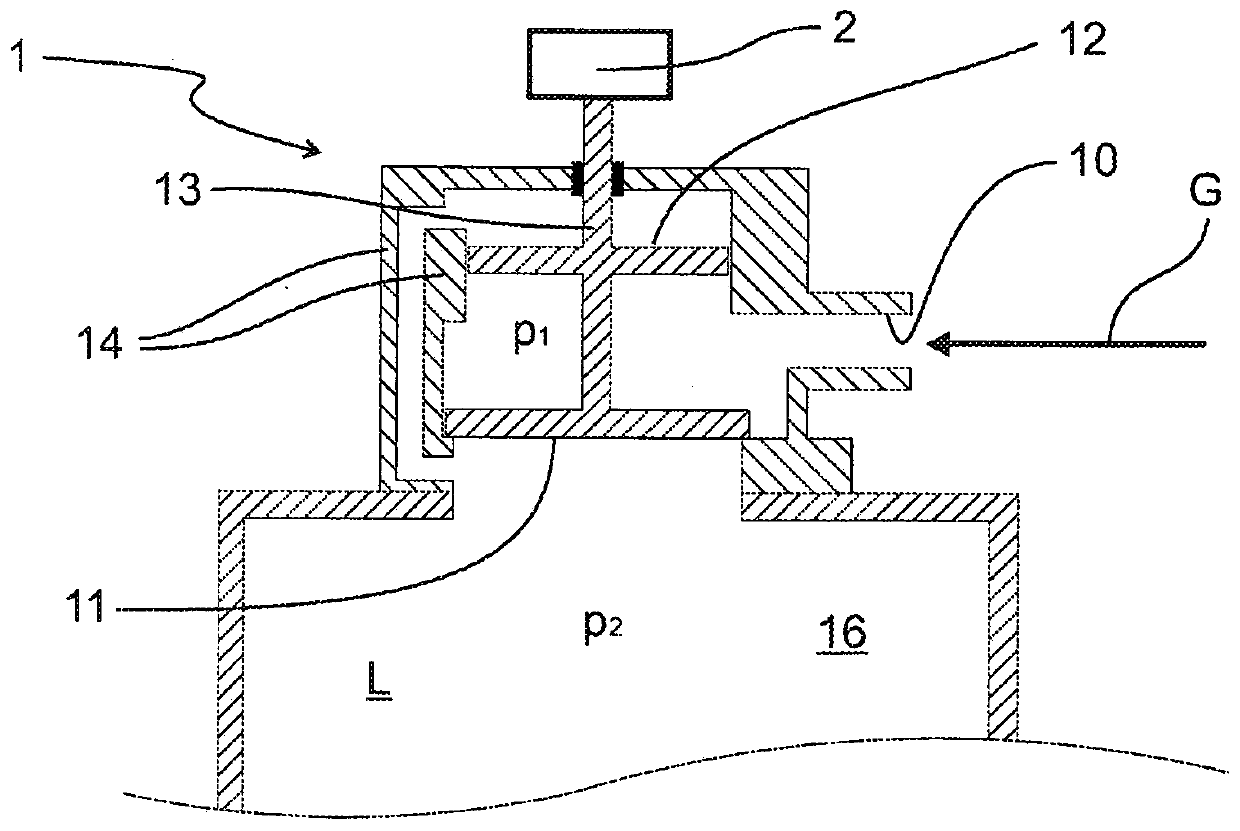

[0040] exist figure 1 A test rig is shown in , with which the flow characteristics of the gas valve 1 to be used can be determined. The test rig includes a measuring path into which the gas valve 1 is first fitted in the closed state and then loaded with a defined source pressure and drop pressure. It should be noted here that the source pressure and the drop pressure (that is to say the pressure situation at the valve) always correspond to values which also occur during actual engine-driven operation. The reduced pressure corresponding to the loading air pressure is here typically at 1 bar abs and 6 bar abs In the range between, while the source pressure corresponds to the (reduced) tank pressure of the gas tank minus the system pressure loss. Typical tank pressure is max 10 bar abs , of course this can also vary. For different pressure situations, gas temperatures and opening durations, the valve is now open and the flow rate is determined measuring-technically. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com