Enhanced motor device

An enhanced motor technology, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as damage, irreparable motor devices, and inability to adapt to the operating requirements of the manufacturing industry, and achieve easy assembly and removal High-speed heat accumulation and high sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in connection with the drawings and embodiments.

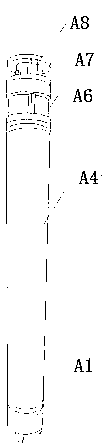

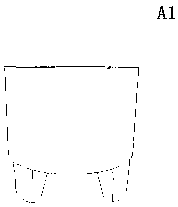

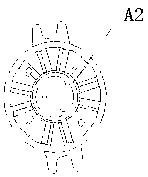

[0021] Such as Figure 1-Figure 8 As shown, the enhanced motor device has a support platform A1, a bottom barrier device A2, a bottom traction slewing bearing A3, an iron core with a cable A4, a high-power rotating shell A5, a top traction slewing bearing A6, and a fixed connection Support plate A7 and connection part A8;

[0022] The bottom barrier device A2 is equipped in the support platform A1, and the bottom traction type slewing bearing A3 is equipped at a higher position of the bottom barrier device A2.

[0023] The iron core A4 with cable is hooped outside the motor in addition, and the high-power rotary shell A5 is equipped with in the iron core A4 with cable.

[0024] The lower position of the high-power rotary shell A5 is connected with the bottom traction type slewing bearing A3, and the higher position of the iron core A4 with cables is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com